Abstract

We report ongoing experiments on the growth of GaN by hydride vapor phase epitaxy (HVPE), using a newly designed Aixtron horizontal reactor. Growth was carried out on c-plane Al2O3 substrates on which a thin GaN layer had been predeposited by MOVPE and patterned using a dielectric mask. The mask pattern was designed to give information on the growth rate and morphology along different directions, and contained both a star-shaped pattern and arrays of parallel stripes of various widths and orientations. All growths were performed at atmospheric pressure and ~1050°C deposition temperature. For the range of experimental conditions investigated the maximum ratios of lateral to vertical growth velocities of around 2 and coalescence of the layer after approximately 10 μm of growth were observed for stripes oriented along the \(\langle 1\bar 100\rangle \) direction.

Similar content being viewed by others

1 Introduction

One of the key problems remaining in the growth of GaN and (Al,Ga,In)N mixed crystals is the lack of an appropriate substrate. One of the solutions proposed consists of the realization of self supported GaN layers grown by Hydride Vapor Phase Epitaxy to be used as pseudo-homoepitaxial substrates [1]. More recently, the use of the Epitaxial Lateral Overgrowth (ELOG) technique has been shown to be effective for the reduction of dislocation densities of GaN grown on sapphire by several orders of magnitude [2]. The combination of HVPE growth with the ELOG technique thus appears as the most promising approach to high crystalline quality. Hydride VPE has already been used successfully for selective epitaxy of other III/V compounds as GaAs [3] or InP [4]. The high selectivity and large growth rate anisotropy which are typical features of HVPE clearly make this method very suitable for such a growth on partially masked substrates [5], [6], [7].

2 Experimental

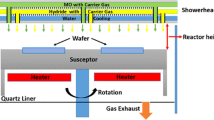

The growth experiments were performed in a newly designed horizontal AIXTRON reactor. A schematic drawing of the reaction chamber heated by a 5 zones furnace is presented in Figure 1. A single two inch wafer can be loaded on the substrate holder which is gas foil rotated. Gallium chloride is synthesized by the reaction of HCl flowing over metallic gallium at high temperature and is transported separately from NH3 in different quartz tubes to the deposition zone where the two species are mixed.

All experiments were performed at atmospheric pressure with nitrogen as carrier gas. The flow rate for ammonia was maintained at 1.2 l/min. while the HCl flow over Ga was varied from 10 to 40 cc/min. The total flow in the reactor was kept constant at 6 l/min. Source temperature and deposition temperature were 850 ° C and 1050 ° C respectively. By varying the GaCl partial pressure, growth rates from 10 to 50 μm/h were obtained and layers with up to 100 μm thickness have been grown. Thickness variations were below 15% over the total surface of a 2 inch wafer.

No nucleation step or GaCl pre-treatment have been used, but ammonia was introduced in the reactor during the heating up of the system from 600 °C to the deposition temperature when patterned substrates were used. The ammonia flux was also maintained during cool down after growth to 700 °C to prevent any degradation of the GaN films. An HCl etching of the reaction chamber was carried out after each growth run in order to eliminate the parasitic deposits of polycrystalline GaN observed on the quartz parts near the deposition zone.

Sapphire (0001) and patterned substrates have been used in this study. The patterned substrates consist of GaN pre-deposited on sapphire by MOCVD, covered by a dielectric SiO2 mask in which stripes with various orientations are opened. Three kinds of patterns are designed on the same mask shown in Figure 2a and Figure 2b: A star shaped pattern with stripes of 5μm width and oriented at 5° increment; Arrays of parallel stripes of 5 and 10 μm width and 5, 10, 50 and 100 μm separation, repeated 12 times at 10° increment; an array of hexagonal holes. Using this mask we can investigate a variety of geometries in a single run, at the same time ensuring that the different structures are grown under identical conditions.

3 Results

3.1 Growth on (0001)-Al2O3

Prior to the growth on patterned substrates GaN layers have been deposited directly on sapphire substrates to determine growth conditions for selective epitaxy. Standard structural and optical characterizations of these layers consisted of X-ray diffraction, photoluminescence, and Hall measurement. Typical values of FWHM for rocking curves of X-ray diffraction were in the range of 600-700 arcsec. Using a ZnO buffer layer, 300 arcsec have been obtained by Molnar et al. [7]. The photoluminescence spectrum of a 100 μm thick GaN layer recorded at 10 K (Figure 3) is dominated by near band edge excitonic transitions. The main peak at 3.470 eV is associated with the donor bound exciton and exhibits a high energy shoulder attributed to the free exciton transition. The FWHM of this peak is 7 meV, indicating the good optical quality of the layer. The standard donor-acceptor pair recombination (D0A0) is observed at 3.27 eV followed by its phonon replicas. The intensity ratio of band edge to acceptor related transitions is around 30. Room temperature mobilities in the range of 150-200 cm2/Vs and electron concentrations of ~3-5×1018 cm−3 were typically measured for nominally undoped layers which are consistent with previous reports [5], [8].

Surface roughness has been investigated both by optical and scanning electron microscopy. The layers are colorless and transparent but exhibit an important surface roughness since no preparation of the surface has been performed prior the growth. Optical microscopy top views of the GaN surface are presented in Figure 4. The height of the pyramids are in the range of 1 to 3 μm and have diameters up to 100 μm.

Besides surface roughness cracks which form due to different thermal expansion coefficients of GaN and sapphire upon cooling down of the sample after growth are a problem. For thick layers important sample bowing is observed - a minimum curve radius of 35 cm has been measured for a 100 μm thick GaN layer on a 300 μm thick sapphire substrate which corresponds to values calculated by Hiramatsu et al. [9] - and the cracks are much more pronounced in the sapphire substrate than in the GaN layer. In addition some of the GaN layers were observed to spontaneously separate from the substrate due to thermally induced stress, yielding free standing GaN platelets of up to 10×10 mm2 size.

3.2 Growth on patterned substrates

The Figure 5 shows the GaN grown on star patterned stripes. The overgrown GaN layer exhibits different facets with cross sectional shapes varying from triangular to rectangular, respectively, for the < \(\overline {11} 20\)) and < \(1\overline 1 00\)) directions for the range of experimental conditions investigated, in agreement with earlier data [2], [10], [11], [12]. Maximum lateral/vertical growth ratio of around 2 is obtained for the < \(1\overline 1 00\)) directions whereas the lateral growth rate for stripes with triangular cross sections is almost zero. The coalescence is observed to occur more rapidly for stripes opened along < \(1\overline 1 00\)) orientation, leading to a continuous GaN film after approximately 10 μm of growth (Figure 7a, Figure 7b). The surface is free of visible voids observed by optical and scanning electron microscopy.

4 Conclusion

GaN layers directly grown on (0001)-Al2O3 have been characterized by X-ray diffraction, photoluminescence and Hall effect measurements. XRD rocking curves exhibit FWHM in the range of 600 arcsec. PL spectra are dominated by a narrow excitonic peak with a FWHM of 7 meV. Results of growth experiments performed on patterned substrates showed a marked anisotropy in the growth behavior along the different directions of the stripe seeds. For this, the most favorable conditions, i.e. parallel stripes along the < \(1\overline 1 00\)) direction with a low ratio between masked and opened surfaces, were found to be optimal. In the range of experimental conditions investigated, optimum results in terms of growth anisotropy and layer coalescence were observed for stripes oriented along the < \(1\overline 1 00\)) direction.

References

Yu.V. Melnik, K.V. Vassilevski, I.P. Nikitina, A.I. Babanin, V. Yu. Davydov, V.A. Dmitriev, MRS Internet J. Nitride Semicond. Res. 2, 39 (1997).

A Usui, H Sunakawa, A Sakai, AA Yamaguchi, Jpn. J. Appl. Phys. 36, L899 (1997).

D. Pribat, V. Provendier, M. Dupuy, P. Legagneux, C. Collet, Jpn. J. Appl. Phys. 30, L431–L434 (1991).

O. Parillaud, E. Gil-Lafon, B. Gérard, P. Etienne, D. Pribat, Appl. Phys. Lett. 68, 2654 (1996).

T. Detchprohm, K. Hiramatsu, H. Amano, I. Akasaki, Appl. Phys. Lett. 61, 2688–2690 (1992).

Y. Kato, S. Kitamura, K. Hiramatsu, N. Sawaki, J. Cryst. Growth 144, 133 (1994).

R.J. Molnar, W. Götz, L.T. Romano, N.M. Johnson, J. Cryst. Growth 178, 147–156 (1997).

R. J. Molnar, K. B. Nichols, P. Maki, E. R. Brown, I. Melngailis, Mater. Res. Soc. Symp. Proc. 378, 479 (1995).

K. Hiramatsu, T. Detchprohm, J. Akasaki, Jpn. J. Appl. Phys. 32, 1528 (1993).

K. Hiramatsu, H. Matsushima, T. Shibata, N. Sawaki, K. Tadatomo, H. Okagawa, Y. Ohuchi, Y. Honda, T. Matsue, Mater. Res. Soc. Symp. Proc. 482, 257 (1998).

B. Beaumont, P. Gibart, M. Vaille, S. Haffouz, G. Nataf, A. Bouillé, J. Cryst. Growth 189/190, 97 (1998).

O-H Nam, MD Bremser, TS Zheleva, RF Davis, Appl. Phys. Lett. 71, 2638–2340 (1997).

Acknowledgments

We thank the CRHEA-CNRS and Aixtron for providing some of the MOVPE starting layers used in this work. The low temperature PL measurements were performed by B. Beaumont of the CRHEA-CNRS laboratory. The work was supported by the ESPRIT-LAQUANI project and the Swiss National Science Foundation.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Parillaud, O., Wagner, V., Buehlmann, H.J. et al. Localized Epitaxy of GaN by HVPE on patterned Substrates. MRS Internet Journal of Nitride Semiconductor Research 3, 40 (1998). https://doi.org/10.1557/S1092578300001125

Received:

Accepted:

Published:

DOI: https://doi.org/10.1557/S1092578300001125