Abstract

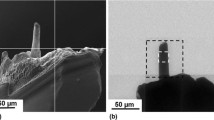

Spray-dried ceramic powders (e.g., Al2O3) are composed of a plurality of granules, each of which, includes ceramic particles and organic binders. It is assumed that the binders become concentrated in the surface layer of the granule in accordance with its type or its volume mixed into a ceramic portion of the granule. However, evidence to prove the assumption was limited because conventional microscopes were not able to clearly visualize the segregation. This paper presents a technique for imaging detailed structure of the spray-dried ceramic powders with the ultrasonic-atomic force microscope (U-AFM). The distribution of binder vis-a-vis Al2O3 particles is highly resolved with good contrast. The distribution was confirmed by nano -indentation. Thus, the U-AFM is shown to be a useful diagnostic tool for the development of approaches to spray-dried process evaluation.

Similar content being viewed by others

References

S. J. Lukasiewicsz, “Spray-Drying Ceramic Powders”, Journal of the American Ceramics Society, Vol. 72, No. 4, 1989, pp. 617–624

Y. Zhang, M. Kawasaki, K. Ando, Z. Kato, N. Uchida and K. Uematsu, “Surface Segregation of PVA during Drying of PVA-Water-Al2O3 Slurry”, Journal of the Ceramic Society of Japan, Vol. 100, No. 8, 1992, pp. 1070–1073

U. Rabe, and W. Arnold, “Acoustic Microscopy by Atomic Force Microscopy”, Applied Physics Letters, Vol. 64, No. 12, 1994, pp. 1493–1495

W. Gao, B. R. Tittmann, and C. Miyasaka, “Contrast Mechanism of Ultrasonic-Atomic Force Microscope”, presented at IEEE 1999 Ultrasonic Symposium (1999)

L. Jia, M. Mandanas, C Miyasaka, B. R. Tittmann, and G.L. Messing, “Analysis of Organic Binder Distribution in Spray Dried Granules by Ultrasonic-Atomic Force Miceroscopy,” Proceedings of SPIE’s International Symposium on Nondestructive Evaluation Techniques for Aging Infrastructure & Manufacturing, 1999, pp. 270–281

M. C. Bhardwaj, “Nondestructive testing of green ceramics by contact-free ultrasound”, ULTRAN’s sales materials.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Miyasaka, C., Jia, L. & Tittmann, B.R. Material Analysis by Ultrasonic Atomic Force Microscopy. MRS Online Proceedings Library 627, 18 (2000). https://doi.org/10.1557/PROC-627-BB1.8

Published:

DOI: https://doi.org/10.1557/PROC-627-BB1.8