Abstract

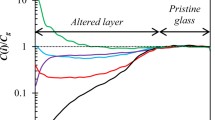

A wide variety of plutonium-containing wastes have been generated from both defense and commercial nuclear programs. The Advanced Mixed Waste Treatment Project (AMWTP) involves the privatized treatment of 65,000 m3 of mixed TRU and low-level waste that is in storage at DOE’s INEEL site. BNFL Inc. leads the commercial team including GTS Duratek, Inc., that has been selected to design, construct, and operate a facility to perform that service. Since vitrification is a potential treatment option, the current study was conducted to investigate issues surrounding the incorporation of the approximately 700 kg of plutonium that is present in the AMWTP waste. A series of glasses were prepared with plutonium (0.5 wt%), with cerium (as a potential surrogate), with both, and with neither. Scanning electron microscopy coupled with energy dispersive x-ray spectroscopy (SEM-EDS) and optical analyses confirmed that both elements were completely dissolved into the as-melted glasses. Heat treatments forced the formation of secondary phases, which were analyzed for Pu and Ce incorporation. Plutonium-containing glasses were spiked with sulfates and remelted to force the formation of a sulfate salt phase, which was analyzed to determine partitioning of Pu and Ce. Coupons of Monofrax K-3 glass contact refractory were exposed to melts of these glasses for six days at 1208°C using both standard and modified versions of ASTM procedure C621-84. Thickness loss, microstructural alteration, and the extent to which Pu and Ce were incorporated into the material were then determined by methods employing SEMEDS⫳velength dispersive x-ray spectroscopy (WDS). Extreme heat treatments were found to lead to the formation of small amounts (< 0.1 vol%) of either (Pu, Ce)O2, or PuO2, depending upon whether Ce was present or absent, respectively. The Pu level in the sulfate phase was at least a factor often below that of the parent glass, and no tendency to concentrate Pu in the K-3 refractory above the level in the parent glass was found.

Similar content being viewed by others

References

I. S. Muller and I. L. Pegg, “Glass Formulation and Testing with AMWTP Waste Simulants,” VSL Final Report, June 1998.

K. S. Matlack, I. S. Muller, and I. L. Pegg, “Results of Melter Tests Using AMWTP Waste Simulants,” VSL Final Report, June 1998.

I. S. Muller, A. C. Buechele, F. Perez-Cardenas, H. Gan, and I. L. Pegg, “Distribution of Plutonium between AMWTP Glass, Secondary Phases, and Contact Refractories,” VSL Final Report, June 1998.

W. Lutze, in Radioactive Waste Form for the Future, Eds. W. Lutze and R.C. Ewing (1988).

C. T. Walker and U. Riege, Ceramics in Nuclear Waste Management, Cincinnati, CONF-790420, eds T.C. Chikalla and J.E. Mendel (Technical Information Center) p. 198 (1979).

H. Gan, A. C. Buechele, and I. L. Pegg, “Corrosion of K-3 Refractory in M-Area, West Valley, and TWRS Glasses,” VSL Final Report to GTS Duratek, Inc., September 1997.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Muller, I.S., Buechele, A.C., Perez-Cardenas, F. et al. Partitioning of Plutonium between Glass, Secondary Phases, and Contact Refractories. MRS Online Proceedings Library 556, 271 (1998). https://doi.org/10.1557/PROC-556-271

Published:

DOI: https://doi.org/10.1557/PROC-556-271