Abstract

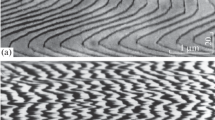

Ni removal from Si wafers by low-pressure UV/Cl2 chemical vapor cleaning (CVC) was investigated at substrate temperatures of 150–200°C. Sub-monolayer Ni coverages were applied to Si(100) by ultrahigh-vacuum physical vapor deposition (UHV-PVD). The Ni surface concentration was reduced to the Auger electron spectroscopy (AES) detection limit by a 2-min UV/Cl2 exposure at 300 mTorr and 200°C. AES depth profiling revealed that Ni was not contained within nor buried beneath the chlorosilyl layer formed by UV/Cl2 CVC. In contrast, Ni was not removed under similar conditions from Si surfaces covered by a thin UV/air oxide layer. These results indicate that Ni removal from Si occurs by a photochemical etching mechanism and not by direct volatilization of NiCl2. Atomic force microscopy (AFM) of Si surfaces after UV/Cl2 CVC indicated that Si etching was limited ~20 Å and that the surface was smooth (RMS roughness = 1.6 Å).

Similar content being viewed by others

References

T. Ito, R. Sugino, Y. Sato, M. Okuno, A. Osawa, T. Aoyama, T. Yamazaki, and Y. Arimoto in Chemical Surface Preparation, Passivation and Cleaning for Semiconductor Growth and Processing, edited by R. J. Nemanich, C. R. Helms, M. Hirose, and G. W. Rubloff (Mater. Res. Soc. Proc. 259, Pittsburgh, PA, 1992) pp. 195–205.

A. S. Lawing, A. J. Muscat, H. H. Sawin, and J. W. Butterbaugh in Cleaning Technology in Semiconductor Device Manufacturing IV, edited by R. E. Novak and J. Ruzyllo (The Electrochemical Society, Pennington, NJ, 1996) pp. 150–157.

Y. Ma, M. L. Green, K. Torek, J. Ruzyllo, R. Opila, K. Konstandinidis, D. Siconolfi, and D. Brasen, J. Electrochem. Soc. 142, L217 (1995).

R. Sugino, Y. Nara, H. Horie, and T. Ito, J. Appl. Phys. 76, 5498 (1994).

T. Ito, R. Sugino, S. Watanabe,. Y. Nara, and Y. Sato in Cleaning Technology in Semiconductor Device Manufacturing, edited by R. E. Novak and J. Ruzyllo (The Electrochemical Society, Pennington, NJ, 1990) pp. 114–120.

R. Sugino, Y. Okui, M. Shigeno, S. Okubo, K. Takasaki, and T. Ito in Proceedings of the 1995 International Symposium on Semiconductor Manufacturing (1995) pp. 262–265.

B. E. Deal and C. R. Helms, in Handbook of Semiconductor Wafer Cleaning Technology, edited by W. Kern (Noyes Publications, Park Ridge, N.J., 1993) p. 316.

S Bedge, J. McFadyen, and H.H. Lamb in Chemical Surface Preparation, Passivation and Cleaning for Semiconductor Growth and Processing, edited by R. J. Nemanich, C. R. Helms, M. Hirose, and G. W. Rubloff (Mater. Res. Soc. Proc. 259, Pittsburgh, PA, 1992) pp. 207–212.

S.G. Bedge, PhD thesis, North Carolina State University, (1994).

E. J. Van Loenen, J. F. Van Der Veen, and F. K. LeGoues, Surface Science 157, 1 (1985).

V. A. Ukrainstev and J. T. Yates, Jr., Surface Science 346, 31 (1996).

J. T. Yates Jr., private communication.

S. K. Janikowski, L. J. Radonovich, T. J. Groshens, and K. J. Klabunde, Organometallics 4, 396 (1985).

Acknowledgments

This work was supported by the NSF Engineering Research Center for Advanced Electronic Materials Processing at North Carolina State University. We would like to thank W. T. Evans formerly of ALCOA for anodizing the sample heater and D. Bachelor, J. Richards, and L.L. Smith for AFM operation.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Courtney, C.H., Lamb, H.H. Ni Removal from Si Wafers by Low-Pressure UV-Chlorine Cleaning. MRS Online Proceedings Library 477, 487–492 (1997). https://doi.org/10.1557/PROC-477-487

Published:

Issue Date:

DOI: https://doi.org/10.1557/PROC-477-487