Abstract

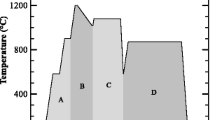

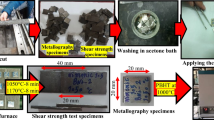

Brazing process is a cost effective technique to repair wide gap cracks in turbine components made from difficult to weld nickel base superalloys. In this process boron and silicon are used as melting point depressants, however, form hard and brittle intermetallic compounds with nickel (eutectic phases) which are detrimental to the mechanical properties of brazed joints. In this paper the effect of brazing parameters such as temperature and time on final microstructure of brazed joint of nickel base superalloy Inconel 738 using a commercial filler metal alloy (Ni-11Cr-3.5Si-2.25B-3.5Fe) was investigated. The microstructure of the joint layer was characterized by optical and scanning electron microscopy; chemical composition was carried out by energy dispersive X-ray spectrometry (EDS) microanalysis and microhardness testing. The results showed that the formation of eutectic microconstituents, within the joint regions, was significantly influenced by the brazing parameters and gap size, also that formation of eutectic constituents decreased by allowing a sufficient amount of time for a complete isothermal solidification to take place at the brazing temperature.

Similar content being viewed by others

References

J.H.G. Mattheij, Mater. Sci. Technol. 1, 608 (1985).

S.D. Duvall, W.A. Owczarski, Weld. J. 46, 423 (1967).

J. Matthew and J. Stephen, Superalloys. A Technical Guide. ASM Internacional. Second edition. (2002).

R. Johnson, M. Baron and N.J. Livesey, Third International Brazing and Soldering Conference (BABS), Paper 21, 1979.

Tung, Lim, and Lai, Scripta Materialia. 34, 763 (1996).

E. Lugsscheider, H. Schmoor, U. Eritt, Brazing, High Temperature Brazing and Diffusion Welding, Deutscher Verlag fur Schweisstechnik GmbH, Germany, 259–261 (1995).

D. S. Duvall, W. A Owczarski and D. F. Paulonis, Welding J. 53, 203 (1974).

M. Pouranvari, A. Ekrami, A.H. Kokabi, J. Alloys Compd. 461, 641 (2008).

O.A. Ojo, N.L. Richards, M.C. Charturvedi, Sci. Technol.Weld. Joining 9, 209 (2004).

K. Ohsasa, T. Shinmura, T. Narita, J. Phase Equilib. 20, 199 (1999).

R. Rosenthal, D.R.F. West, Mater. Sci. Technol. 15, 1387 (1999).

W.F. Gale, E.R. Wallach, Metall. Trans. A22, 2451 (1991).

R.D. Eng, E.J. Ryan and J.R. Doyle, Welding Journal 56, 15 (1977).

M.H. Haatkens, SAB Technical Paper Series, l-15, Oct. 1982.

T.J. Kelly, Welding Journal 61, 317 (1982).

J. W. Chasteen and G.E. Metzger, Welding Journal 58, 11l (1979).

Hans van Esch and G. Marijnissen, Turbomachinery International 9, 29 (1986).

E. Lugscheider and Th. Schittny, Brazing and Soldering 14, 27 (1988).

K. G. Gove, Metals and Materials 5, 341 (1989).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Aguilar, A., Esparza, R., Gil, M.A. et al. Brazing Process to Repair Wide Gap Cracks of Inconel 738 Superalloy Components. MRS Online Proceedings Library 1242, 457 (2009). https://doi.org/10.1557/PROC-1242-S4-57

Published:

DOI: https://doi.org/10.1557/PROC-1242-S4-57