Abstract

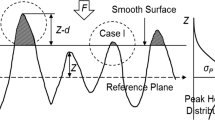

To improve yield rates during integrated circuit fabrication a better understanding of the material removal process during CMP is sought. Many material removal models have been generated to predict the material removal rate (MRR) during CMP. The majority of such models estimate that the MRR is equal to the material removed by a single particle multiplied by the total number of particles contributing to the wear process. Particles contributing to the wear process are known as ‘active particles’. Several authors have proposed analytical models to estimate this quantity. This work introduces a new method for estimating the number of active particles in CMP by deducing it from the polish results of a multi-physics CMP model. By employing the particle-augmented mixed lubrication model (PAML) developed by Terrell and Higgs (2008), it is possible to determine the number of active particles in CMP. The predictions of PAML are compared with two popular analytical approaches which have been commonly used to predict the number of active particles during CMP.

Similar content being viewed by others

References

Goodarz Ahmadi, Xun Xia, “A model for Mechanical Wear and Abrasive Particle Adhesion during the Chemical Mechanical Polishing Process,” Journal of The Electrochemical Society, vol. 148, pp. 99–109, 2001.

Yongwu Zhao, L. Chang, “A micro-contact and wear model for chemical-mechanical polishing of silicon wafers,” WEAR, vol.252, 2001.

D. Castillo-Mejia, S. Beaudoin, “A Locally Relevant Wafer-Scale Model for CMP of Silicon Dioxide,” Journal of The Electrochemical Society, vol. 150, pp. 581–586, 2003.

E. J. Terrell and C. F. Higgs, “A Particle-Augmented Mixed Lubrication Modeling Approach to Predicting Chemical Mechanical Polishing,” Journal of Tribology-Transactions of the Asme, vol. 131, p. 10, Jan 2009.

S. Chandrasekar, et al., “ Mechanics of Polishing,” Transactions of the ASME, vol.65, 1998.

J. F. Luo and D. A. Dornfeld, “Material removal mechanism in chemical mechanical polishing: Theory and modeling,” Ieee Transactions on Semiconductor Manufacturing, vol. 14, pp. 112–133, May 2001

Ashraf Bastawros, Abhijit Chandra, Yongjin Gao, Bo Yan, “Pad Effects on Material-Removal Rat in Chemical-Mechanical Planarization”, Journal of Electronic Materials, vol. 31, No. 10, 2002.

J.F. Luo and D.A. Dornfeld, “Effects of Abrasive Size Distribution in Chemical Mechanical Planarization: Modeling and Verification” Ieee Transactions on Semiconductor Manufacturing, vol. 16, pp. 469–476, August 2003

W. Che, et al., “Mechanistic understanding of material detachment during micro-scale polishing,” Journal of Manufacturing Science and Engineering-Transactions of the Asme, vol. 125, pp. 731–735, 2003.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Mpagazehe, J.N., Thukalil, G. & Higgs, C.F. A Study to Estimate the Number of Active Particles in CMP. MRS Online Proceedings Library 1157, 202 (2008). https://doi.org/10.1557/PROC-1157-E02-02

Received:

Accepted:

Published:

DOI: https://doi.org/10.1557/PROC-1157-E02-02