Abstract

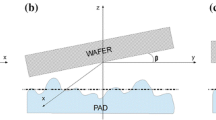

A multi-physics model encompassing chemical dissolution and mechanical abrasion effects in CMP is developed. This augments a previously developed multi-scale model accounting for both pad response and slurry behavior evolution. The augmented model is utilized to predict scratch propensity in a CMP process. The pad response delineates the interplay between the local particle level deformation and the cell level bending of the pad. The slurry agglomerates in the diffusion limited agglomeration (DLA) or reaction limited agglomeration (RLA) regime. Various nano-scale slurry properties significantly influence the spatial and temporal modulation of the material removal rate (MRR) and scratch generation characteristics. The model predictions are first validated against experimental observations. A parametric study is then undertaken. Such physically based models can be utilized to optimize slurry and pad designs to control the depth of generated scratches and their frequency of occurrence per unit area.

Similar content being viewed by others

References

Martinez, M.A, 1994, Solid State Technology.

Komanduri R, 1996, On material removal mechanisms in finishing of advanced ceramics and glasses, Annals of the CIRP, 45:509–514.

Evans, C.J., Paul, E., Dornfeld, D., Lucca, D.A., Byrne, G., Tricard, M., Klocke, F., Dambon, O., Mullany, B.A, 2003, Material removal mechanisms in lapping and polishing, Annals of the CIRP, 52/2:611–634.

Wang, C., Sherman, P., Chandra, A., Dornfeld, D., 2005, Pad Surface Roughness and Slurry Particle Size Distribution Effects on Material Removal Rate in Chemical Mechanical Planarization, Annals of the CIRP, 54/1:309–312.

Bastawros, A.F., Chandra, A., Guo, Y., Yan, B., 2002, Pad Effects on Material Removal Rate in Chemical Mechanical Planarization, J. Electronic Materials, 31/10:1–10.

Luo, J., Dornfeld, D., 2003, Effects of abrasive size distribution in chemical mechanical planarization: modeling and verification, IEEE Trans. Semiconductor Manufacturing, 16/3:469–476.

Lin, M Y., Lindsay, H.M., Weitz, D.A., Klein, R., Ball R.C., Meakin, P., 1989, Universality of Fractal Aggregates as Probed by Light Scattering, Proceedings of the Royal Society of London A, 423/1864:71–87.

Lin, M Y., Lindsay, H.M., Weitz, D.A., Klein, R., Ball R.C., Meakin, P., 1990, Universal diffusion-limited colloid aggregation, Journal of Physics: Condensed Matter, 2:3093–3113.

Ball, R.C., Weitz, D.A., Witten, T.A., Leyvraz, F., 1987, Universal kinetics in reaction limited aggregation, Physical Review Letters, 58/3.

Komulski, Marek, 2001, Chemical properties of material surfaces, New York.

Che, W., Guo, Y.J., Chandra, A., Bastawros, A., 2005, A Scratch Intersection Model of Material Removal During Chemical Mechanical Planarization (CMP), Journal of Manufacturing Science and Engineering, 127/3:545–554.

Bastaninejad, M., Goodarz, A., 2005, Modeling the Effects of Abrasive Size Distribution, Adhesion and Surface Plastic Deformation on Chemical-Mechanical Polishing, J. of The Electrochemical Society, 152/9:1875–1877.

Che W, Bastawros A, Chandra A, et al., Surface evolution during the chemical mechanical planarization of copper, CIRP Annals-Manufacturing Technology, Volume: 55, Issue: 1, Pages: 605–608 Published: 2006.

Chandra, A., P, Karra and M, Dorothy., Implications of Arrow’s Theorem in Modeling of Multiscale Phenomena: An Engineering Approach, Submitted to Journal of Design, also presented at NSF CMMI Grantee conference, Knoxville, Jan 2008.

Chandra, A., Unpublished work, 2009.

Armini, S., 2007, Composite particles for chemical-mechanical planarization applications, Dissertation, IMEC, Kapeldreef 75, Leuven, Belgium.

Gopal, T., Talbot, J.B., Use of Slurry Colloidal Behavior in Modeling of Material Removal Rates in CMP, Journal of The Electrochemical Society, 154/6, H507–H511, 2007.

Boroucki, L,. Mathematical Modeling of Polish-rate Decay in Chemical-Mechanical Polishing, Journal of Engineering Mathematics 43, 105–114, 2002.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Chandra, A., Bastawros, A.F. & Karra, P.K. Understanding Multi Scale Pad Effects in Chemical Mechanical Planarization. MRS Online Proceedings Library 1157, 201 (2008). https://doi.org/10.1557/PROC-1157-E02-01

Received:

Accepted:

Published:

DOI: https://doi.org/10.1557/PROC-1157-E02-01