Abstract

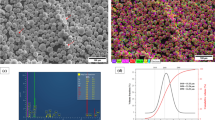

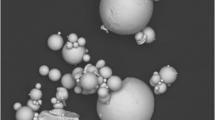

Ultrafine-grained samples were produced from a Ni nanopowder by hot isostatic pressing (HIP) and spark plasma sintering (SPS). The microstructure and mechanical behavior of the two specimens were compared. The grain coarsening observed during the SPS procedure was moderated due to a reduced temperature and time of consolidation compared with HIP processing. The smaller grain-size and higher nickel-oxide content in the SPS-processed sample resulted in a higher yield strength. Compression experiments showed that the specimen produced by SPS reached a maximal flow stress at a small strain, which was followed by a long steady-state softening while the HIP-processed sample hardened until failure. It was revealed that the softening of the SPS-processed sample resulted from microcracking along the grain boundaries.

Similar content being viewed by others

References

V.M. Segal Materials processing by simple shear. Mater. Sci. Eng., A 197, 157 1995

R.Z. Valiev R.K. Islamgaliev I.V. Alexandrov: Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 45, 103 2000

R.Z. Valiev, Y. Estrin, Z. Horita, T.G. Langdon, M.J. Zehetbauer, Y.T. Zhu: Producing bulk ultrafine-grained materials by severe plastic deformation. JOM 58, 33 2006

A. Dubravina, M.J. Zehetbauer, E. Schafler, I.V. Alexandrov: Correlation between domain size obtained by x-ray Bragg profile analysis and macroscopic flow stress in severely plastically deformed copper. Mater. Sci. Eng., A 387–389, 817 2004

P.G. Sanders, C.J. Youngdahl, J.R. Weertman: The strength of nanocrystalline metals with and without flaws. Mater. Sci. Eng., A 234–236, 77 1997

H.V. Atkinson, S. Davies: Fundamental aspects of hot isostatic pressing: An overview. Metall. Mater. Trans. A 31, 2981 2000

Y. Champion, F. Bernard, N. Guigue-Millot, P. Perriat: Sintering of copper nanopowders under hydrogen: An in situ x-ray diffraction analysis. Mater. Sci. Eng., A 360, 258 2003

J. Gubicza, G. Dirras, P. Szommer, B. Bacroix: Microstructure and flow stress of ultrafine grained aluminum processed by hot isostatic pressing. Mater. Sci. Eng., A 458, 385 2007

S. Billard, J.P. Fondere, B. Bacroix, G.F. Dirras: Macroscopic and microscopic aspects of the deformation and fracture mechanisms of ultrafine-grained aluminum processed by hot isostatic pressing. Acta Mater. 54, 411 2006

W. Chen, U. Anselmi-Tamburini, J.E. Garay, J.R. Groza, Z.A. Munir: Fundamental investigations on the spark plasma sintering/synthesis process: I. Effect of dc pulsing on reactivity. Mater. Sci. Eng., A 394, 132 2005

R. Chaim: Densification mechanisms in spark plasma sintering of nanocrystalline ceramics. Mater. Sci. Eng., A 43, 25 2007

M. Trunec, K. Macaa, Z. Shen: Warm pressing of zirconia nanoparticles by the spark plasma sintering technique. Scr. Mater. 59, 23 2008

S. Paris, E. Gaffet, F. Bernard, Z.A. Munir: Spark plasma synthesis from mechanically activated powders: A versatile route for producing dense nanostructured iron aluminides. Scr. Mater. 50, 691 2004

F. Tepper: Electro-explosion of wire produces nanosize metals. Met. Powder Rep. 53, 31 1998

Y. Kwon, Y. Jung, N. Yavorovsky, A. Illyn: Ultra-fine powder by wire explosion method. Scr. Mater. 44, 2247 2001

G. Ribárik, J. Gubicza, T. Ungár: Correlation between strength and microstructure of ball milled Al-Mg alloys determined by x-ray diffraction. Mater. Sci. Eng., A 387–389, 343 2004

L. Balogh, G. Ribárik, T. Ungár: Stacking faults and twin boundaries in fcc crystals determined by x-ray diffraction profile analysis. J. Appl. Phys. 100, 023512 2006

A.P. Zhilyaev, B-K. Kim, J.A. Szpunar, M.D. Baro, T.G. Langdon: The microstructural characteristics of ultrafine-grained nickel. Mater. Sci. Eng., A 391, 377 2005

Y. Zhao, T. Topping, J.F. Bingert, J.J. Thornton, A.M. Dangelewicz, Y. Li, W. Liu, Y. Zhu, Y. Zhou, E.J. Lavernia: High tensile ductility and strength in bulk nanostructured nickel. Adv. Mater. 20, 3028 2008

B. Hasni: Mechanical characterization of fine-grained materials subjected to large deformations under monotoneous and cyclic stresses. M.Sc. Thesis University of Paris Paris, France 2007

D.P. Field, B.W. True, T.M. Lillo, J.E. Flinn: Observation of twin boundary migration in copper during deformation. Mater. Sci. Eng., A 372, 173 2004

P. Müllner, C. Solenthaler: On the effect of deformation twinning on defect densities. Mater. Sci. Eng., A 230, 107 1997

V. Yamakov, D. Wolf, S.R. Phillpot, H. Gleiter: Dislocation–dislocation and dislocation–twin reactions in nanocrystalline Al by molecular dynamics simulation. Acta Mater. 51, 4135 2003

M. Chen, E. Ma, K.J. Hemker, H. Sheng, Y. Wang, X. Cheng: Deformation twinning in nanocrystalline aluminium. Science 300, 1275 2003

A. Froseth, H. Van Swygenhoven, P.M. Derlet: The influence of twins on the mechanical properties of nc-Al. Acta Mater. 52, 2259 2004

L. Lu, Y. Shen, X. Chen, L. Qian, K. Lu: Ultrahigh strength and high electrical conductivity in copper. Science 304, 422 2004

L. Rémy: Twin-slip interaction in f.c.c. crystals. Acta Metall. 25, 711 1977

L. Lu, R. Schwaiger, Z.W. Shan, M. Dao, K. Lu, S. Suresh: Nano-sized twins induce high rate sensitivity of flow stress in pure copper. Acta Mater. 53, 2169 2005

I.A. Ovidko: Deformation of nanostructures. Science 295, 2386 2002

D. Jia, K.T. Ramesh, E. Ma: Effects of nanocrystalline and ultrafine grain sizes on constitutive behavior and shear bands in iron. Acta Mater. 51, 3495 2003

I. Sabirov, Y. Estrin, M.R. Barnett, I. Timokhina, P.D. Hodgson: Tensile deformation of an ultrafine-grained aluminium alloy: Micro shear banding and grain boundary sliding. Acta Mater. 56, 2223 2008

F.J. Humphreys, J.W. Martin: The effect of dispersed phases upon dislocation distributions in plastically deformed copper crystals. Philos. Mag. 16, 927 1968

L.J. Kecskes, K.C. Cho, R.J Dowding, B.E. Schuster, R.Z. Valiev, Q. Wei: Grain size engineering of bcc refractory metals: Top-down and bottom-up—Application to tungsten. Mater. Sci. Eng., A 467, 33 2007

Acknowledgments

We are grateful for the support of the Hungarian TeT Foundation (KPI) under Contract No. F-47/2006 (Balaton project). This work was supported by the Hungarian Scientific Research Fund, OTKA, Grant Nos. K67692 and K71594. J.G. is grateful for the support of a Bolyai Janos Research Scholarship of the Hungarian Academy of Sciences and the help of Noemi Szasz in x-ray diffraction experiments. G.F.D. is grateful for the support of ÉGIDE, in the framework of the Hubert Curien Project (PHC Balaton).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gubicza, J., Bui, HQ., Fellah, F. et al. Microstructure and mechanical behavior of ultrafine-grained Ni processed by different powder metallurgy methods. Journal of Materials Research 24, 217–226 (2009). https://doi.org/10.1557/JMR.2009.0010

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2009.0010