Abstract

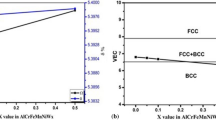

Amorphous Ti66Nb13Cu8Ni6.8Al6.2 alloy powders with different tungsten carbide (WC) contents were synthesized by mechanical alloying. Outstanding differences in particle size, thermal stability, glass-forming ability, and phase evolution are found for the synthesized Ti-based glassy powders with different WC contents. This is attributed to the fact that the WC was partially alloyed into the glassy matrix and the matrix element Ti was also partially alloyed into the WC particles. The obtained glassy powders exhibit a wide supercooled liquid region above 64 K. Meanwhile, the main crystalline phase is the ductile β-Ti with a high volume fraction in the crystallized alloy powders. These two aspects offer the possibility of easily preparing a plasticity-enhanced bulk composite in the supercooled liquid region by powder metallurgy, which couples the nanosized WC particles with in situ precipitated ductile β-Ti phase.

Similar content being viewed by others

References

W.H. Wang, C. Dong, C.H. Shek: Bulk metallic glasses. Mater. Sci. Eng., R 44, 45 2004

A. Inoue: Stabilization of metallic supercooled liquid and bulk amorphous alloys. Acta Mater. 48, 279 2000

A.I. Salimon, M.F. Ashby, Y. Bréchet, A.L. Greer: Bulk metallic glasses: What are they good for? Mater. Sci. Eng., A 375–377, 385 2004

A. Inoue: Bulk amorphous and nanocrystalline alloys with high functional properties. Mater. Sci. Eng., A 304–306, 1 2001

H.C. Yim, R.D. Conner, F. Szuecs, W.L. Johnson: Processing, microstructure and properties of ductile metal particulate reinforced Zr57Nb5Al10Cu15.4Ni12.6 bulk metallic glass composites. Acta Mater. 50, 2737 2002

K.B. Kim: Formation of in-situ nanoscale Ag particles in (Ti0.33Zr0.33Hf0.33)40(Ni0.33Cu0.33Ag0.33)50Al10 alloy with wide supercooled liquid region. Mater. Lett. 59, 1117 2005

F.Q. Guo, H.J. Wang, S.J. Poon, G.J. Shiflet: Ductile titanium- based glassy alloy ingots. Appl. Phys. Lett. 86, 091907 2005

Y.C. Kim, W.T. Kim, D.H. Kim: A development of Ti-based bulk metallic glass. Mater. Sci. Eng., A 375, 127 2004

G. He, W. Löser, J. Eckert: Devitrification and phase transformation of (Ti0.5Cu0.25Ni0.15Sn0.05Zr0.05)100–xMox metallic glasses. Scripta Mater. 50, 7 2004

Y.K. Xu, H. Ma, J. Xu, E. Ma: Mg-based bulk metallic glass composites with plasticity and gigapascal strength. Acta Mater. 53, 1857 2005

H.M. Fu, H.F. Zhang, H. Wang, Q.S. Zhang, Z.Q. Hu: Synthesis and mechanical properties of Cu-based bulk metallic glass composites containing in-situ TiC particles. Scripta Mater. 52, 669 2005

H.C. Yim, R. Busch, W.L. Johnson: The effect of silicon on the glass forming ability of the Cu47Ti34Zr11Ni8 bulk metallic glass forming alloy during processing of composites. J. Appl. Phys. 83, 7993 1998

M.H. Lee, J.Y. Lee, D.H. Bae, W.T. Kim, D.J. Sordelet, D.H. Kim: A development of Ni-based alloys with enhanced plasticity. Intermetallics 12, 1133 2004

Y.K. Xu, J. Xu: Ceramics particulate reinforced Mg65Cu20 Zn5Y10 bulk metallic glass composites. Scripta Mater. 49, 843 2003

Z. Bian, R.J. Wang, W.H. Wang, T. Zhang, A. Inoue: Carbon-nanotube-reinforced Zr-based bulk metallic glass composites and their properties. Adv. Funct. Mater. 14, 55 2004

H.C. Yim, R. Busch, U. Köster, W.L. Johnson: Synthesis and characterization of particulate reinforced Zr57Nb5Al10Cu15.4Ni12.6 bulk metallic glass composites. Acta Mater. 47, 2455 1999

G. He, J. Eckert, W. Löser: Stability, phase transformation and deformation behavior of Ti-base metallic glass and composites. Acta Mater. 51, 1621 2003

C. Fan, R.T. Ott, T.C. Hufnagel: Metallic glass matrix composite with precipitated ductile reinforcement. Appl. Phys. Lett. 81, 1020 2002

U. Kühn, J. Eckert, N. Mattern, L. Schultz: ZrNbCuNiAl bulk metallic glass matrix composites containing dendritic bcc phase precipitates. Appl. Phys. Lett. 80, 2478 2002

H. Ma, J. Xu, E. Ma: Mg-based bulk metallic glass composites with plasticity and high strength. Appl. Phys. Lett. 83, 2793 2003

X.L. Fu, Y. Li, C.A. Schuh: Contributions to the homogeneous plastic flow of in situ metallic glass matrix composites. Appl. Phys. Lett. 87, 241904 2005

C.C. Hays, C.P. Kim, W.L. Johnson: Microstructure controlled shear band pattern formation and enhanced plasticity of bulk metallic glasses containing in situ formed ductile phase dendrite dispersions. Phys. Rev. Lett. 84, 2901 2000

G. He, J. Eckert, W. Löser, L. Schultz: Novel Ti-base nanostructure–dendrite composite with enhanced plasticity. Nat. Mater. 2, 33 2003

U. Kühn, N. Mattern, A. Gebert, M. Kusy, M. Boström, U. Siegel, L. Schultz: Nanostructured Zr- and Ti-based composite materials with high strength and enhanced plasticity. J. Appl. Phys. 98, 054307 2005

J. Eckert, U. Kühn, J. Das, S. Scudino, N. Radtke: Nanostructured composite materials with improved deformation behavior. Adv. Eng. Mater. 7, 587 2005

J. Eckert, A. Reger-Leonhard, B. Weiß, M. Heilmaier, L. Schultz: Bulk nanostructured multicomponent alloys. Adv. Eng. Mater. 3, 41 2001

J. Eckert, A. Kübler, L. Schultz: Mechanically alloyed Zr55Al10Cu30Ni5 metallic glass composites containing nanocrystalline W particles. J. Appl. Phys. 85, 7112 1999

Y.L. Wang, J. Xu, R. Yang: Glass formation in high-energy ball milled Tix(Cu0.45Ni0.55)94–xSi4B2 alloys. Mater. Sci. Eng., A 352, 112 2003

L.C. Zhang, J. Xu, E. Ma: Mechanically alloyed amorphous Ti50(Cu0.45Ni0.55)44−xAlxSi4B2 alloys with supercooled liquid region. J. Mater. Res. 17, 1743 2002

L.C. Zhang, Z.Q. Shen, J. Xu: Glass formation in a (Ti,Zr,Hf)–(Cu,Ni,Ag)–Al high-order alloy system by mechanical alloying. J. Mater. Res. 18, 2141 2003

J. Eckert: Mechanical alloying of highly processable glassy alloys. Mater. Sci. Eng., A 226–228, 364 1997

M.S. El-Eskandarany, M. Omori, A. Inoue: Solid-state synthesis of new glassy Co65Ti20W15 alloy powders and subsequent densification into a fully dense bulk glass. J. Mater. Res. 20, 2845 2005

P.Y. Lee, W.C. Liu, C.K. Lin, J.C. Huang: Fabrication of Mg–Y–Cu bulk metallic glass by mechanical alloying and hot consolidation. Mater. Sci. Eng., A 449–451, 1095 2007

P.P. Choi, J.S. Kim, O.T.H. Nguyen, D.H. Kwon, Y.S. Kwon, J.C. Kim: Al-La-Ni-Fe bulk metallic glasses produced by mechanical alloying and spark-plasma sintering. Mater. Sci. Eng., A 449–451, 1119 2007

I.K. Jeng, C.K. Lin, P.Y. Lee: Formation and characterization of mechanically alloyed Ti–Cu–Ni–Sn bulk metallic glass composites. Intermetallics 14, 957 2006

I.K. Jeng, P.Y. Lee: Mechanically alloyed tungsten carbide particle/Ti50Cu28Ni15Sn7 glassy alloy matrix composites. Mater. Sci. Eng., A 449–451, 1090 2007

M. Tokita: Trends in advanced SPS spark plasma sintering system and technology. J. Soc. Powder Technol. Jpn. 30, 790 1993

D. Turnbull: Under what conditions can a glass be formed? Contemp. Phys. 10, 473 1969

P.P. Chattopadhyay, P.M.G. Nambissan, S.K. Pabi, I. Manna: Polymorphic bcc to fcc transformation of nanocrystalline niobium studied by positron annihilation. Phys. Rev. B 63, 054107 2001

I. Manna, P.P. Chattopadhyay, P. Nandi, F. Banhart, H-J. Fecht: Formation of face-centered-cubic titanium by mechanical attrition. J. Appl. Phys. 93, 1520 2003

Y.Y. Li, C. Yang, W.P. Chen, X.Q. Li, M. Zhu: Oxygen-induced amorphization of metallic titanium by ball milling. J. Mater. Res. 22, 1927 2007

Titanium and Titanium Alloys, edited by C. Leyens and M. Peters, translated into Chinese by Z.H. Chen {etet al.} Chemical Industry Press Beijing, People’s Republic of China 2005 8

Binary Alloy Phase Diagrams, edited by S. Nagasaki and M. Hirabayashi in Japanese AGNE Gijutsu Center, Co., Ltd. Tokyo, Japan 2002), translated into Chinese by A.S. Liu (Metallurgical Industry Press, Beijing, People’s Republic of China, 2004 227

Acknowledgments

This work was supported by the National Science Fund of China for Distinguished Young Scholars (No. 50325516), the National High Technology Research and Development Program of China (No. 2007AA03Z112), the MOST (No. 2007CB616905), the Guangdong Natural Science Foundation (No. 07300579), the China Postdoctoral Science Foundation (No. 20060390198), and the Postdoctoral Innovation Foundation of South China University of Technology (No. 05243). The authors are very grateful to Senior Engineer X.F. Ruan from Wuhan University for his technical assistances in the SPS experiments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Y., Yang, C., Chen, W. et al. Effect of WC content on glass formation, thermal stability, and phase evolution of a TiNbCuNiAl alloy synthesized by mechanical alloying. Journal of Materials Research 23, 745–754 (2008). https://doi.org/10.1557/JMR.2008.0087

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2008.0087