Abstract

Adopting glass fluxing and cyclic superheating, high undercooling up to ∼550 K was achieved in bulk eutectic Ni78.6Si21.4 alloy melt. With increasing undercooling, the as-solidified microstructure shows an interesting evolution, i.e., regular lamellar eutectic, coarse directional dendrite, quasi-spherical dendritic colony, fine directional dendrite, fine quasi-spherical dendritic colony, and superfine anomalous eutectic. In combination with different theories for nucleation and growth, the microstructure evolution was analyzed and described using competitions incorporated in rapid solidification of the bulk undercooled eutectic Ni78.6Si21.4 alloy. For undercooling below and above 180 K, Ni3Si, and α-Ni are primarily solidified, respectively. This phase selection can be ascribed to competitive nucleation. As undercooling increases, a transition of the prevalent nucleation mode from site saturation to continuous nucleation was interpreted in terms of competition of nucleation mode. Accordingly, the superfine anomalous eutectic is obtained, due to the substantially increased continuous nucleation rate, i.e., grain refinement occurring at high undercooling (e.g., ∼550 K).

Similar content being viewed by others

References

J. Lipton, W. Kurz R. Trivedi: Rapid dendrite growth in undercooled alloys. Acta Metall. 35, 957 1987

J.D. Hunt K.A. Jackson: Nucleation of solid in an undercooled liquid by cavitation. J. Appl. Phys. 37, 254 1965

K.A. Jackson J.D. Hunt: Lamellar and rod eutectic growth. Trans. AIME 236, 1129 1966

R. Trivedi, P. Magnin W. Kurz: Theory of eutectic growth under rapid solidification conditions. Acta Metall. 35, 971 1987

K.A. Jackson, J.D. Hunt D.R. Uhlmann: On origin of equiaxed zone in casting. Trans. Met. Soc. AIME 236(2), 149 1966

T.Z. Kattamis M.C. Flemings: Dendrite structure and grain size of undercooled melts. Trans. Met. Soc. AIME 236, 1523 1966

G.L.F. Powell: The influence of oxygen content on the grain size of undercooled silver. Trans. Met. Soc. AIME 245, 1785 1969

F. Liu G.C. Yang: Stress-induced recrystallization mechanism fro grain refinement in highly undercooled superalloy. J. Cryst. Growth 231, 295 2001

F. Liu, D.W. Zhao G.C. Yang: Solidification of undercooled molten Ni-based alloys. Metall. Mater. Trans. B 32(3), 449 2001

F. Liu, X.F. Guo G.C. Yang: Structure evolution in undercooled DD3 single crystal superalloy. Mater. Sci. Eng., A 291(1–2), 9 2000

W. Kurz D.J. Fisher: Solidification microstructures: Eutectics and peritectics in Fundamentals of Solidification edited by W. Kurz and D.J. Fisher Trans Tech Publications Ltd. Switzerland 1998 Chap. 5, p. 93

J.H. Perepezko: Kinetic processes in undercooled melts. Mater. Sci. Eng., A 226–228, 374 1997

J.H. Perepezko: Nucleation-controlled reactions and metastable structures. Prog. Mater. Sci. 49, 263 2004

R. Goetzinger, M. Barth D.M. Herlach: Growth of lamellar eutectic dendrites in undercooled melts. J. Appl. Phys. 84, 1643 1998

R.F. Cochrane, A.L. Greer, K. Eckler D.M. Herlach: Dendrite growth velocities in undercooled Ni–Si alloys. Mater. Sci. Eng., A 133, 698 1991

Y.P. Lu, G.C. Yang, C.L. Yang Y.H. Zhou: Directional solidification of highly undercooled eutectic Ni78.6Si21.4 alloy. Mater. Lett. 59, 1558 2005

S. Milenkovic R. Caram: Effect of the growth parameters on the Ni–Ni3Si eutectic microstructure. J. Cryst. Growth 95, 237 2002

R. Goetzinger, M. Barth D.M. Herlach: Mechanism of formation of the anomalous eutectic structure in rapidly solidified Ni–Si, Co–Sb and Ni–Al–Ti alloys. Acta Mater. 46, 1647 1988

M. Leonhardt, W. Löser H.G. Lindenkreuz: Metastable phase formation in undercooled eutectic Ni78.6Si21.4 melts. Mater. Sci. Eng., A 271, 31 1999

T.Z. Kattamis M.C. Flemings: Structure of undercooled Ni–Sn eutectic. Metall. Trans. 1, 1449 1970

B.L. Jones: Growth mechanisms in undercooled eutectics. Metall. Trans. 2, 2950 1971

B. Wei, D.M. Herlach, B. Feuerbacher F. Sommer Dendritic and eutectic solidification of undercooled Co–Sb alloys. Acta Metall., 41, 1801 (1993)

B. Wei D.M. Herlach Dendrite growth in undercooled monotectic alloys, (Advanced Materials’ 93), Trans. Mater. Res. Soc. Jpn., 14A, 639 (1994)

P. Nash A. Nash: Phase Diagrams of Binary Nickel Alloy ASM International Materials Park, OH 1991 22

J.W. Christian: The classical theory of nucleation in The Theory of Transformation in Metals and Alloys edited by J.W. Christian Pergamon Press Oxford, England 1975 Chap. 10, p. 418

D. Turnbull: Kinetics of solidification of supercooled liquid mercury droplets. J. Chem. Phys. 20, 411 1952

G.R. Wood A.G. Waltons: Homogeneous nucleation kinetics of ice from water. J. Appl. Phys. 41, 3027 1970

E.J. Mittemeijer F. Sommer: Solid-state phase transformation kinetics: A modular transformation model. Z. Metallkd. 93, 5 2002

F. Liu, F. Sommer E.J. Mittemeijer: An analytical model for isothermal and isochronal transformation kinetics. J. Mater. Sci. 39, 1621 2004

E.J. Mittemeijer: Analysis of the kinetics of phase transformations. J. Mater. Sci. 27, 3977 1992

F. Liu, F. Sommer E.J. Mittemeijer: Determination of nucleation and growth mechanisms of the crystallization of amorphous alloys; application to calorimetric data. Acta Mater. 52, 3207 2004

A.T.W. Kempen, F. Sommer E.J. Mittemeijer: The isothermal and isochronal kinetics of the crystallisation of bulk amorphous Pd40Cu30P20Ni10. Acta Mater. 50, 1319 2002

H. Nitsche, F. Sommer E.J. Mittemeijer: The Al nano-crystallization process in amorphous Al85Ni8Y5Co2. J. Non-Cryst. Solids. 351, 3760 2005

F. Liu, F. Sommer E.J. Mittemeijer: Parameter determination of an analytical model for phase transformation kinetics: application to crystallization of amorphous Mg–Ni alloys. J. Mater. Res. 19(9), 2586 2004

W. Oldfield: A quantitative approach to casting solidification. Trans. ASM 59, 945 1966

W.J. Boettinger, S.R. Coriell R. Trivedi: Rapid Solidification Processing: Principles and Technologies IV edited by R. Mehrabian, P.A. Parrish Claitor’s Baton Rouge LA 1988 13

M.J. Aziz: Model for solute redistribution during rapid solidification. J. Appl. Phys. 53, 1158 1982

Y.P. Lu, F. Liu, G.C. Yang, H.P. Wang Y.H. Zhou: Grain refinement in solidification of highly undercooled eutectic Ni–Si alloy. Mater. Lett. 61(4–5), 987 2007

Y.P. Lu, F. Liu, G.C. Yang Y.H. Zhou: Composite growth in highly undercooled Ni70.2Si29.8 eutectic alloy. Appl. Phys. Lett. 89, 241902 2006

F. Spaepen: A structural model for the solid–liquid interface in monatomic systems. Acta Metall. 23, 729 1975

G. Wilde, J.L. Sebright J.H. Perepezko: Bulk liquid undercooling and nucleation in gold. Acta Mater. 54, 4759 2006

M. Schwarz, A. Karma, K. Eckler D.M. Herlach: Physical mechanism of grain refinement in solidification of undercooled melts. Phys. Rev. Lett. 73, 1380 1994

R. Willnecker, G.P. Görler G. Wilde: Appearance of a hypercooled liquid region for completely miscible alloys. Mater. Sci. Eng., A 226–228, 439 1997

M. Li, T. Ishikawa, K. Nagashio, K. Kuribayashi S. Yoda: Experimental evidence of crystal fragmentation from highly undercooled Ni99B1 melts processed on an electrostatic levitator. Metall. Mater. Trans. A 36A, 3254 2005

Acknowledgments

The authors are grateful for the financial support of New Century Excellent Person Supporting Project (NCET-05-870), the Fundamental Research Project of National Defense of China (A2720060295), the Project Sponsored by the Scientific Research Foundation for the Returned Overseas Chinese Scholars, State Education Ministry (N6CJ0002), the Scientific and Technological Creative Foundation of Youth in Northwestern Polytechnical University, and the Natural Science Foundation of China (Grant Nos. 50501020, 50395103, and 50431030). F. Liu is also grateful to the Fundamental Research Fund of Northwestern Polytechnical University. F. Liu appreciates Dr. Yao Wenjing for numerical calculations.

Author information

Authors and Affiliations

Corresponding author

APPENDIX: Calculation of f(Θ) for α-Ni and Ni3Si Phases

APPENDIX: Calculation of f(Θ) for α-Ni and Ni3Si Phases

In the undercooled melts, the critical condition for crystallization can be given as

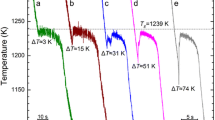

where V is the volume of sample, tN is the nucleation time that can be directly obtained from the measured temperature–time profile, and N is the number of nucleation events, which can be assumed to be the number of dendritic grain or eutectic colony. V and tN, with respect to ΔT = 180 K where both α-Ni and Ni3Si are assumed to be able to nucleate, are listed in Table I. As shown in Fig. 3, N is equal to 6.97 × 103 at ΔT =180 K, Then, applying Eq. (A1), the value of J at ΔT = 180 K was calculated as 5 × 106 m−3s−1. In combination with Eq. (3), f(θ) for α-Ni and Ni3Si phases can be calculated as 0.26 and 0.39, respectively. Because of the structural difference between α-Ni and Ni3Si, the catalyzed effect of heterogeneities on their nucleation was certainly expected to be quite different. Thus, f(θ) values for α-Ni and Ni3Si phases should certainly be different.

Rights and permissions

About this article

Cite this article

Liu, F., Chen, Y., Yang, G. et al. Competitions incorporated in rapid solidification of the bulk undercooled eutectic Ni78.6Si21.4 alloy. Journal of Materials Research 22, 2953–2963 (2007). https://doi.org/10.1557/JMR.2007.0380

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2007.0380