Abstract

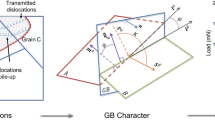

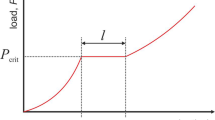

Using depth-sensing indentation, a pop-in phenomenon induced by grain boundaries, namely, a sudden indenter displacement jump when indented near a grain boundary segment, was observed in polycrystalline niobium. This grain-boundary type of pop-in occurs at a larger force than the initial elasto-plastic pop-in, which is observed with and without a grain boundary nearby. The experimental results show that this pop-in effect has a close relationship with the misorientation across the grain boundary. The occurrence of this pop-in phenomenon is rationalized in terms of slip transmission across the grain boundary.

Similar content being viewed by others

References

K.T. Aust, R.E. Hanneman, P. Niessen, and J.H. Westbrook: Solute induced hardening near grain boundaries in zone refined metals. Acta Metall. 16, 291 (1968).

T. Watanabe, S. Kitamura, and S. Karashima: Grain-boundary hardening and segregation in alpha-iron-tin alloy. Acta Metall. 28, 455 (1980).

L.B. Harris, V.R. Howes, and N.G. Cutmore: Microhardness of NaCl bicrystals. J. Am. Ceram. Soc. 65, 35 (1982).

Y.T. Chou, B.C. Cai, Jr., A.D. Romig, and L.S. Lin: Correlation between grain-boundary hardening and grain-boundary energy in niobium bicrystals. Philos. Mag. A 47, 363 (1983).

Z.Q. Zhou and Y.T. Chou: Structure dependence of grain-boundary hardening in oriented niobium bicrystals. J. Less. Comm. Met. 114, 323 (1985).

J.W. Wyrzykowski and M.W. Grabski: The Hall-Petch relation in aluminum and its dependence on the grain-boundary structure. Philos. Mag. A 53, 505 (1986).

C.S. Lee, G.W. Han, R.E. Smallman, D. Feng, and J.K.L. Lai: The influence of boron-doping on the effectiveness of grain boundary hardening in Ni3Al. Acta Mater. 47, 1823 (1999).

P.C. Wo and A.H.W. Ngan: Investigation of slip transmission behavior across grain boundaries in polycrystalline Ni3Al using na-noindentation. J. Mater. Res. 19, 189 (2004).

G.K. Baranova: Etching of dislocations in niobium single-crystals. Scripta Metall. 11, 827 (1977).

T.F. Page, W.C. Oliver, and C.J. McHargue: The deformation-behavior of ceramic crystals subjected to very low load (nano)in-dentations. J. Mater. Res. 7, 450 (1992).

W.W. Gerberich, J.C. Nelson, E.T. Lilleodden, P. Anderson, and J.T. Wyrobek: Indentation induced dislocation nucleation: The initial yield point. Acta Mater. 44, 3585 (1996).

S.A. Syed Asif and J.B. Pethica: Nanoindentation creep of single-crystal tungsten and gallium arsenide. Philos. Mag. A 76, 1105 (1997).

D.F. Bahr, D.E. Kramer, and W.W. Gerberich: Non-linear deformation mechanisms during nanoindentation. Acta Mater. 46, 3605 (1998).

T.A. Michalske and J.E. Houston: Dislocation nucleation at nano-scale mechanical contacts. Acta Mater. 46, 391 (1998).

A. Gouldstone, H.J. Koh, K.Y. Zeng, A.E. Giannakopoulos, and S. Suresh: Discrete and continuous deformation during nanoin-dentation of thin films. Acta Mater. 48, 2277 (2000).

Y.L. Chiu and A.H.W. Ngan: Time-dependent characteristics of incipient plasticity in nanoindentation of a Ni3Al single crystal. Acta Mater. 50, 1599 (2002).

Y.L. Chiu and A.H.W. Ngan: A TEM investigation on indentation plastic zones in Ni3Al(Cr,B) single crystals. Acta Mater. 50, 2677 (2002).

D. Kramer, H. Huang, M. Kriese, J. Robach, J. Nelson, A. Wright, D. Bahr, and W.W. Gerberich: Yield strength predictions from the plastic zone around nanocontacts. Acta Mater. 47, 333 (1999).

K. Ishio, K. Kikuchi, M. Kusano, M. Mizumoto, K. Mukugi, A. Naito, N. Ouchi, and Y. Tsuchiya: Fracture toughness and mechanical properties of pure niobium and welded joints for superconducting cavities at 4K. In Proceedings of the 9th Workshop on RF Superconductivity, edited by B. Rusnak (Santa Fe, NM, 1999), Organized by Los Alamos National Laboratory, NM, Published online at http://lansce.lanl.gov/rfsc99/.

K.L. Johnson, Contact Mechanics (Cambridge University Press, Cambridge, U.K., 1985), pp. 173.

K. Zeng, E. Söderlund, A.E. Giannakopoulos, and D.J. Rowcliffe: Controlled indentation: A general approach to determine mechanical properties of brittle materials. Acta Mater. 44, 1127 (1996).

P.R.V. Evans: The dependence of the lower yield stress on grain size in niobium. J. Inst. Met. 92, 57 (1963).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wang, M.G., Ngan, A.H.W. Indentation strain burst phenomenon induced by grain boundaries in niobium. Journal of Materials Research 19, 2478–2486 (2004). https://doi.org/10.1557/JMR.2004.0316

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2004.0316