Abstract

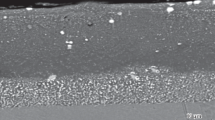

A complex-shaped TiAl turbine rotor has been uniformly aluminized by a metal-organic chemical vapor deposition under reduced pressure (RPMOCVD), and a thick TiAl3 layer, which affects the oxidation resistance, can be formed on the surface by subsequent heat treatment. The oxidation resistance has been studied with an oxidation test at 1173 K for 760 ks in static air. The microstructure has been investigated by SEM, EPMA, AES, and XRD. A heat treatment at above 933 K, which is the melting point of Al, is required to enhance the oxidation resistance of TiAl. With increasing the surface roughness of TiAl, the formation of TiAl3 increases, and consequently the oxidation resistance is more improved.

Similar content being viewed by others

References

H. A. Lipsitt, in High-Temperature Ordered Intermetallic Alloys, edited by C. C. Koch, C. T. Liu, and N. S. Stoloff (Mater. Res. Soc. Symp. Proc. 39, Pittsburgh, PA, 1985), p. 351.

M. Yoshihara and R. Tanaka, Bull. Jpn. Inst. Metals 30 (1), 61 (1991).

E. Kobayashi, M. Yoshihara, and R. Tanaka, J. Jpn. Inst. Metals 53, 251 (1989).

Y. Nishiyama, T. Miyashita, S. Isobe, and T. Noda, in High Temperature Aluminides and Intermetallics, edited by S. H. Whang, C.T. Liu, D.P. Pope, and J.O. Stiegler (The Minerals, Metals and Materials Society, Warrendale, PA, 1990), pp. 557–584.

S. Taniguchi, Bull. Jpn. Inst. Metals 31, 497 (1992).

S. Taniguchi, T. Shibata, and K. Takeuchi, Mater. Trans. JIM 32, 299 (1991).

F.A. Clay, Final Report, BDX-613–866 (Rev.) Aug., Bendix Corp., Kansas (1973).

H. O. Pierson, Thin Solid Films 45, 257 (1977).

A. Malazgirt and J. W. Evans, Metall. Trans. B 11B, 225 (1980).

L. Vandenbulcke, Thin Solid Films 102, 149 (1983).

Y. Umakoshi, M. Yamaguchi, T. Sakagami, and T. Yamane, J. Mater. Sci. 24, 1599 (1989).

H. Furukawa, in Proc. Bohshoku Gijutsu Symposium on High Temperature Oxidation of Intermetallic Compounds (Japan Society of Corrosion Engineering, Tokyo, Japan, 1991), pp. 54–59.

T. Suzuki and H. Umehara, J. Jpn. Inst. Metals 51, 577 (1987).

K. Kasahara, M. Takeyama, and T. Tsujimoto, Proc. Bohshoku Gijutsu Symposium on High Temperature Oxidation of Intermetallic Compounds (Japan Society of Corrosion Engineering, Tokyo, Japan, 1991), pp. 10–17.

H. Hino and K. Tsurumi, Kawasaki Heavy Industries Ltd., private communication (1990).

C.F. Powell, I.E. Campbell, and B.W. Gonser, Vapor-Plating (John Wiley & Sons, New York, 1955), p. 25.

H. Mabuchi, T. Asai, and Y. Nakayama, Scripta Metall. 23, 685 (1989).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Suzuki, T., Umehara, H. & Hino, H. Aluminizing for TiAl turbocharger rotor by reduced pressure metal-organic chemical vapor deposition (RPMOCVD) and the efficiency of its oxidation resistance. Journal of Materials Research 9, 1984–1989 (1994). https://doi.org/10.1557/JMR.1994.1984

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.1994.1984