Abstract

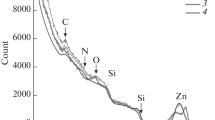

A series of investigations were carried out to evaluate the topographic and structural effects of ion implantation on monolithic Si3N4 ceramic surfaces. Implantations were performed with N2, Ne, or Ar in the fluence range of 2.0 × 1016 to 4 × 1017 particles/cm2 and implant voltages of 125 to 200 keV, depending on the mass of the implanted species. Single crystal Si and SiC were also examined for comparative purposes. Noble gases produced blisters on Si3N4 and significant increases in surface expansion. TEM examination of the Si3N4 blister shell showed a distribution of small bubbles, ranging in size from 5 to 300 nm, depending upon the type of Si3N4, and a transformation of the original crystalline structure into an amorphous phase. Analysis of the blister shell, using electron energy loss spectrometry (EELS) and energy dispersive x-ray spectrometry (EDXS) showed that a significant quantity of the implanted Ar was still present in the blister (skin).

Similar content being viewed by others

References

S.T. Picraux, Annu. Rev. Mater. Sci., edited by R. A. Huggins, J. A. Giordmaine, and J. B. Wachtman, Jr., 14, 335 (1984).

P.J. Burnett and T.F. Page, Conf. Proc. of the Brit. Ceram. Soc, Ceramic Surfaces and Surface Treatments, 34, London (Dec. 1983).

C.J. McHargue, B.R. Appleton, and C.W. White, NATO-ASI, Surface Engineering, edited by R. Kossowsky and S. C. Singhal, NATO ASI Series (Martinus Nijhoff Pub., The Hague, 1984).

P.J. Burnett and T.F. Page, J. Mater. Sci . 19, 3524 (1984).

T Hioki, A. Itoh, S. Noda, H. Doi, J. Kawamoto, and O. Kamigaito, J. Mater. Sci. Lett . 3, 1099 (1984).

C. W. White, C. J. McHargue, P. S. Sklad, L. A. Boatner, and G. C. Farlow, Mater. Sci. Rep . 4 (2–3), July (1989).

A. T. Churchman, R. S. Barnes, and A. H. Cottrell, J. Nucl. Mater . 7, 88 (1958).

R.L. Klueh, Sci. Technol . 5 (Oct. 1969).

G. Knuyt, M. D’Olieslaeger, L. DeScheppa, and L. Stals, Mater. Sci. Eng . 98, 523 (1988).

G.C. Farlow, C.J. McHargue, C.W. White, and B.R. Appleton, Rad. Eff . 97, 257 (1986).

C.J McHargue, G.C. Farlow, M.B. Lewis, and J.M. Williams, Nucl. Instrum. Methods B19/20, 809 (1987).

S. Miyagawa, Y. Ato, and Y. Miyagawa, J. Appl. Phys . 54 (5), 2302 (1983).

S. G. Roberts and T. F. Page, J. Mater. Sci. 21, 457 (1986).

R. S. Bhattacharya, A. K. Raiv, and P. P. Pronko, J. Appl. Phys. 61 (10), 4791 (1987).

J. Cochran, K. O. Legg, and G. R. Baldau, Emergent Process Methods for High Technology Ceramics, edited by R. F. Davis, H. Palmour III, and R. L. Porter, Mater. Sci. Res. 17, 549, Plenum Press (1984).

S.J. Bull and T.F. Page, J. Mater. Sci . 23 (12), 4217 (1988).

SUSPRE, “Surrey University Sputter Profile Resolution from Energy Deposition”, Surrey University, United Kingdom.

J.P. Biersack, Nucl. Instrum. Methods B182/183, 199 (1981).

J.F. Gibbons, Proc. IEEE 60 (6), 1062 (1972).

J. F. Ziegler, The Stopping and Range of Ions in Solids, Ion Implantation: Science and Technology, edited by J. F. Ziegler (Academic Press, Inc., 1984), p. 51.

D. E. Bradley, Techniques for Electron Microscopy, Replica and Shadowing Techniques, edited by D.H. Kay (F. A. Davis Co., Philadelphia, PA, 1965), p. 119.

O. Auciello, Ion Bombardment Modification of Surfaces: Fundamentals and Applications, edited by O. Auciello and R. Kelly (Elsevier Publishing, New York, 1984).

D.W. Oblas and V.K. Sarin, Symposium Proceedings, Ion Implantation and Plasma-Assisted Processes for Industrial Applications, edited by R. Hochman, H. Solnick-Legg, and K. Legg (ASM INTERNATIONAL, Metals Park, OH, 1988).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Oblas, D.W., Sarin, V.K. & Ostreicher, K. Topographic/structure changes of implanted Si3N4 . Journal of Materials Research 7, 2579–2584 (1992). https://doi.org/10.1557/JMR.1992.2579

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.1992.2579