Abstract

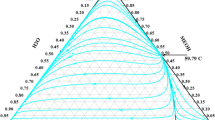

The separation of two systems containing minimum boiling azeotropes (acetone—methanol and tetrahydrofuran (THF)—water) was performed using extractive distillation with a heavy boiling mixed entrainer consisting of two compounds. The entrainer constituents did not form new azeotropes with each other and with the components of the original mixture. An analysis of the mixed entrainer influence on the vapor-liquid equilibrium (VLE) and relative volatility provides an understanding of the cases in which the separation by extractive distillation (ED) in the presence of the mixed entrainer revealed energy benefits over their individual constituents. New results for application of the mixed entrainer monoethanolamine (MEA)—ethylene glycol (EG) and dimethyl-sulphoxide (DMSO)—glycerol for the separation of THF—water and acetone—methanol, respectively, are presented for the first time. The individual selective agents were chosen from the efficient entrainers discussed in the literature. The calculations were performed using the platform Aspen Plus 7.3. Different extractive distillation flowsheets are provided for the zeotropic mixed agents, viz. with two or three columns. For the ED of the binary mixtures investigated, the structures of the different separation schemes, the operating parameters of the columns, and the energy consumptions are presented and compared. The application of the mixed entrainer MEA—EG fed into the ED column with pre-mixing can be recommended, providing up to 1.7 % of energy saving for acetone—methanol separation. In the case of THF—water, the mixed entrainer DMSO—glycerol provides 0.8 % of energy saving. The separate inputs of the individual constituents of the mixed entrainer led to a significant increase in the energy consumptions of the flowsheet because of the third regeneration column, hence this flowsheet cannot be recommended for use in the separation of both mixtures.

Similar content being viewed by others

References

Berg, L., & Yeh, A. I. (1984). The separation of isopropyl ether from methyl ethyl ketone by extractive distillation. Chemical Engineering Communications, 29, 283–289. DOI: 10.1080/00986448408940163.

Berg, L., Yeh, A. I., & Ratanapupech, P. (1985). The recovery of ethyl acetate by extractive distillation. Chemical Engineering Communications, 39, 193–199. DOI: 10.1080/00986448508911670.

Berg, L., Vosburgh, M. G., Christensen, R.W., & Shanahan, M. J. (1988). The separation of lower boiling alcohols by extractive distillation. Chemical Engineering Communications, 66, 1–21. DOI: 10.1080/00986448808940257.

Berg, L., Szabados, R. J., Wendt, K. M., & Yeh, A. I. (1990). The dehydration of the lower fatty acids by extractive distillation. Chemical Engineering Communications, 89, 113–131. DOI: 10.1080/00986449008940563.

Gao, X., Li, X. G., & Li, H. (2010). Hydrolysis of methyl acetate via catalytic distillation: Simulation and design of new technological process. Chemical Engineering and Processing: Process Intensification, 49, 1267–1276. DOI: 10.1016/j.cep.2010.09.015.

Gao, X., Wang, F. Z., Li, H., & Li, X. G. (2014). Heatintegrated reactive distillation process for TAME synthesis. Separation and Purification Technology, 132, 468–478. DOI: 10.1016/j.seppur.2014.06.003.

Gil, I. D., García, L. C., & Rodríguez, G. (2014). Simulation of ethanol extractive distillation with mixed glycols as separating agent. Brazilian Journal of Chemical Engineering, 31, 259–270. DOI: 10.1590/s0104-66322014000100024.

Gmehling, J., & Kleiber, M. (2014). Vapor—liquid equilibrium and physical properties for distillation. In A. Górak, & E. Sorensen (Eds.), Distillation: Fundamentals and principles (pp. 45–95). London, UK: Academic Press. DOI: 10.1016/b978-0-12-386547-2.00002-8.

Gómez, P. A., & Gil, I. D. (2009). Simulation of the tetrahydrofuran dehydration process by extractive distillation. Latin American Applied Research, 39, 275–284.

Harris, R. A., Ramjugernath, D., Letcher, T. M., & Raal, J. D. (2002). Monoethanolamine as an extractive solvent for the n-hexane + benzene, cyclohexane + ethanol, and acetone + methanol binary systems. Journal of Chemical & Engineering Data, 4, 781–787. DOI: 10.1021/je010240+.

Jarvelin, H., & Fair, J. R. (1993). Adsorptive separation of propylene—propane mixtures. Industrial & Engineering Chemistry Research, 32, 2201–2207. DOI: 10.1021/ie00022a001.

Kirk, R. E., & Othmer, D. F. (2007). Kirk-Othmer encylopedia of chemical technology (5th ed., Vol. 8). New York, NY, USA: Wiley-Interscience.

Koczka, K., Maczinger, J., Mizsey, P., & Fonyo, Z. (2007). Novel hybrid separation processes based on pervaporation for THF recovery. Chemical Engineering and Processing Process Intensification, 46, 239–246. DOI: 10.1016/j.cep.2006.05.016.

Lei, Z. G., Li, C. Y., & Chen, B. H. (2003). Extractive distillation: A review. Separation & Purification Reviews, 32, 121–213. DOI: 10.1081/spm-120026627.

Liao, B., Lei, Z. G., Xu, Z., Zhou, R. Q., & Duan, Z. T. (2001). New process for separating propylene and propane by extractive distillation with aqueous acetonitrile. Chemical Engineering Journal, 84, 581–586. DOI: 10.1016/s1385-8947(01)00175-9.

NIST (2001). In P. J. Lindstrom, & W. G. Mallard (Eds.), NIST Chemistry WebBook: NIST standard reference database No. 69. Gaithersburg, MD, USA: National Institute of Standards and Technology.

Luyben, W. L. (2008). Effect of solvent on controllability in extractive distillation. Industrial & Engineering Chemistry Research, 47, 4425–4439. DOI: 10.1021/ie701757d.

Luyben, W., & Chien, I. L. (2010). Design and control of distillation systems for separating azeotropes (pp. 473). Hoboken, NJ, USA: Wiley.

Mahdi, T., Ahmad, A., Nasef, M. M., & Ripin, A. (2015). State-of-the-art technologies for separation of azeotropic mixtures. Separation & Purification Reviews, 44, 308–330. DOI: 10.1080/15422119.2014.963607.

Matsuda, H., Liebert, V., Tochigi, K., & Gmehling, J. (2013). Influence of sulfate-based anion ionic liquids on the separation factor of the binary azeotropic system acetone + methanol. Fluid Phase Equilibria, 340, 27–30. DOI: 10.1016/j.fluid.2012.12.006.

Raeva, V. M., Sazonova, A. Yu., & Frolkova, A. K. (2013). Synergetic effect of binary separating agents in extractive rectification of homogeneous mixtures. Theoretical Foundations of Chemical Engineering, 47, 649–659. DOI: 10.1134/s0040579513050096.

Verma, V. K., & Banerjee, T. (2010). Ionic liquids as entrainers for water + ethanol, water + 2-propanol, and water + THF systems: A quantum chemical approach. The Journal of Chemical Thermodynamics, 42, 909–919. DOI: 10.1016/j.jct.2010.03.001.

Yeh, A. I., Berg, L., & Warren, K. J. (1988). The separation of acetone-methanol mixture by extractive distillation. Chemical Engineering Communications, 68, 69–79. DOI: 10.1080/00986448808940398.

Zhang, Z. G., Huang, D. H., Lv, M., Jia, P., Sun, D. Z., & Li, W. X. (2014). Entrainer selection for separating tetrahydrofuran/water azeotropic mixture by extractive distillation. Separation and Purification Technology, 122, 73–77. DOI: 10.1016/j.seppur.2013.10.051.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Sazonova, A.Y., Raeva, V.M. & Frolkova, A.K. Design of extractive distillation process with mixed entrainer. Chem. Pap. 70, 594–601 (2016). https://doi.org/10.1515/chempap-2015-0247

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1515/chempap-2015-0247