Abstract

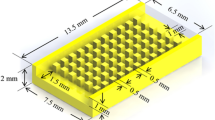

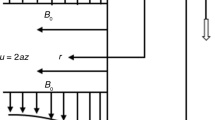

In this work, heat transfer via the cylindrical part of the jacket in an agitated vessel has been investigated. Heat transfer coefficients were determined using the transient method based on measuring the temperature dependency of the liquid batch on time. A multistage impeller made of two impellers was used in a cylindrical vessel with dished bottom. The lower impeller was a curved blade turbine with the diameter of d = 100 mm and the upper impeller was either a pitched three-blade or pitched four-blade impeller with the diameter of d1 = 67 mm. Three different impeller clearances in a multistage configuration, H3/d1 = 1, 1.5, and 2, were used in our measurements. The vessel was equipped with two baffles. Experimental results were evaluated using the Euler’s method and nonlinear regression procedure in the Matlab® software and they are summarized in form of Nusselt number correlations describing their dependency on the Reynolds number.

Similar content being viewed by others

Abbreviations

- a:

-

thermal diffusivity m2 s−1

- B:

-

baffle width m

- c:

-

constant

- cp:

-

specific heat capacity J kg−1 K−1

- D:

-

inner vessel diameter m

- d:

-

lower impeller diameter m

- d:

-

model parameter (Eq. (7))

- d 1 :

-

upper impeller diameter m

- H:

-

liquid height m

- H 2 :

-

height of impeller above bottom m

- H 3 :

-

distance between impellers m

- k:

-

mixing efficiency in Eq. (21)

- M:

-

mass of liquid kg

- m:

-

model parameter (Eq. (5))

- ṁ A :

-

mass flow rate of heating or cooling liquid kg s−1

- N:

-

impeller rotation speed s−1

- n:

-

model parameter (Eq. (5))

- Nu:

-

Nusselt number (= αD/λ)

- P:

-

power W

- Po:

-

power number

- Pr:

-

Prandtl number (= μc p /λ)

- Q̇:

-

heat transfer rate W

- q:

-

heat flux density W m2

- r:

-

model parameter (Eq. (7))

- Re:

-

Reynolds number (= ρNd2/μ)

- S:

-

heat transfer area m2

- s:

-

model parameter (Eq. (5))

- T:

-

temperature °C, K

- T 0 :

-

initial temperature °C, K

- T w :

-

wall temperature °C, K

- T′A:

-

inlet temperature of heating or cooling liquid °C, K

- T″A:

-

outlet temperature of heating or cooling liquid °C, K

- T̄:

-

average temperature °C, K

- t:

-

time s

- V:

-

volume m3

- Vi:

-

viscosity ratio (=μ̄/μw)

- α:

-

heat transfer coefficient W m−2 K−1

- λ:

-

thermal conductivity of agitated liquid W m−1 K−1

- μ:

-

dynamic viscosity of agitated liquid Pa s

- μ̄:

-

dynamic viscosity of mixed liquid at average temperature Pa s

- μw:

-

dynamic viscosity of agitated liquid at the wall of the vessel Pa s

- ν:

-

kinematic viscosity of agitated liquid m2 s−1

- ρ:

-

density of agitated liquid kg m−3

- ρ̄:

-

density of agitated liquid at average temperature kg m−3

References

Bett, J., Chang, D., Comrie, J., Hillcoat, D., & McPhillimy, J. (2014). Mixing equipment with multistage impellers. Students’ project, Czech Technical University in Prague, Prague, Czech Republic.

Breber, G. (1988). Heat transfer in agitated vessel. In D. Chisholm (Ed.), Heat exchanger technology (pp. 157–188). London, UK: Elsevier.

Cummings, G. H., & West, A. S. (1950). Heat transfer data for kettles with jackets and coil. Industrial & Engineering Chemistry, 42, 2303–2313. DOI: 10.1021/ie50491a035.

Edwards, M. F., & Wilkinson, M. A. (1972). Heat transfer in agitated vessels, Part I: Newtonian fluids. The Chemical Engineer, 264, 310–319.

Karcz, J., & Strek, F. (1992). Heat transfer in mechanically stirred gas — liquid system. In R. King (Ed.), Fluid mechanics of mixing. Modelling, operations and experimental techniques (Series Fluid mechanics and its applications, Vol. 10, pp. 163–171). DOI: 10.1007/978-94-015-7973-5_19.

Karcz, J., & Stręk, F. (1995). Heat transfer in jacketed agitated vessels equipped with non-standard baffles. Chemical Engineering Journal, 58, 135–143. DOI: 10.1016/0923-0467(94)02945-8.

Karcz, J. (1999). Studies of local heat transfer in a gas-liquid system agitated by double disc turbines in a slender vessel. Chemical Engineering Journal, 72, 217–227. DOI: 10.1016/s1385-8947(99)00005-4.

Karcz, J. (2003). Studies of heat transfer process in agitated vessels. Trends in Chemical Engineering, 8, 161–182.

Karcz, J., Stręk, F., & Bielka, I. (2008). Heat transfer efficiency for a gas-liquid system agitated in a jacketed vessel equipped with two impellers. Chemical and Process Engineering, 29, 713–725.

Liu, B. Q., Zhang, Y. K., Liu, J. L., Qian, L. Y., Li, P., & Jin, Z. J. (2013). Research on heat transfer performance of coaxial mixer with inner combined impeller. Industrial & Engineering Chemistry Research, 52, 17285–17293. DOI: 10.1021/ie401499f.

Nagata, S. (1975). Mixing: Principles and applications. New York, NY, USA: Wiley.

Petera, K., & Dostál, M. (2007). OPEC: Ohřev a chlazení míchaných vsádek. In Proceedings of the 54th National Congress of Chemical and Process Engineering CHISA 2007, October 15–18, 2007 (0197.pdf, pp. 1–20). Srní, Czech Republic: Czech Society of Chemical Engineering. (in Czech)

Rieger, F., Novák, V., Ditl, P., Fořt, I., Vlček, J., Ludvík, M., Machoň, V., & Medek, J. (1995). Míchání a míchací zařízení. Prague, Czech Republic: Czech Society of Chemical Engineering. (in Czech).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Věříšová, M., Dostál, M., Jirout, T. et al. Heat transfer in a jacketed agitated vessel equipped with multistage impellers. Chem. Pap. 69, 690–697 (2015). https://doi.org/10.1515/chempap-2015-0080

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1515/chempap-2015-0080