Abstract

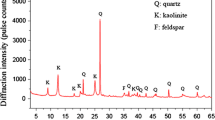

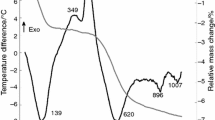

This paper reports the variations of strength, resistivity and thermal parameters of clay after high-temperature heating. Experiments were carried out to test the physical properties of clay heated at temperatures ranging from room temperature to 800°C in a furnace. The experiment results show that below 400°C the uniaxial compressive strength and resistivity change very little. However, above 400°C, both increase rapidly. At a temperature under 400°C, the thermal conductivity and specific heat capacity decrease significantly. The thermogravimetric analysis (TG) and differential scanning calorimeter (DSC) test indicate that a series of changes occur in kaolinite at temperatures from 400 to 600°C, which is considered the primary cause of the variation of physical and mechanical properties of clay under high temperatures.

Article PDF

Similar content being viewed by others

References

Abuel-Naga, H.M., D.T. Bergado, A. Bouazza, and M.J. Pender (2009), Thermal conductivity of soft Bangkok clay form laboratory and field measurements, Eng. Geol. 05, 3–4, 211-219, DOI: 10.1016/j.enggeo.2009.02.008.

Aparicio, P., and E. Galan (1999), Mineralogical interference on kaolinite crystallinity index measurements, Clay. Clay Miner. 47, 1, 12-27, DOI: 10.1346/ CCMN.1999.0470102.

Belloto, M., A. Gualtieri, G. Artioli, and S.-M. Clark (1995), Kinetic study of the kaolinite-mullite reaction sequence. Part II: Mullite formation, Phys. Chem. Minerals 22, 4, 215–222, DOI: 10.1007/BF00202254.

Cai, J.G. (2003), Oregano-clay complexes in muddy sediments and mudstones, Ph.D. Thesis, Tongji University, Shanghai (in Chinese).

Cai, J.G., Y.J. Bao, S.Y. Yang, X.X. Wang, D.D. Fan, J.L. Xu, and A.P. Wang (2007), Research on preservation and enrichment mechanisms of organic matter in muddy sediment and mudstone, Sci. China D 50, 5, 765–775, DOI: 10.1007/s11430-007-0005-0.

De Aza, A.H., X. Turrillas, M.A. Rodriguez, T. Duran, and P. Pena (2014), Timeresolved powder neutron diffraction study of the phase transformation sequence of kaolinite to mullite, J. Eur. Ceram. Soc. 34, 5, 1409–1421, DOI: 10.1016/j.jeurceramsoc.2013.10.034.

Dixon, D.A., M.N. Gray, and A.W. Thomas (1985), A study of the compaction properties of potential clay-sand buffer mixtures for use in nuclear fuel waste disposal, Eng. Geol. 21, 3–4, 247-255, DOI: 10.1016/0013-7952(85) 90015-8.

Dupray, F., C. Li, and L. Laloui (2013), Thermal conductivity of soft Bangkok clay form laboratory and field measurements, Eng. Geol. 63, 113–121, DOI: 10.1016/j.enggeo.2013.05.019.

Gens, A., L. do Guimarães, S. Olivella, and M. Sánchez (2010), Modelling thermohydro-mechano-chemical interactions for nuclear waste disposal, J. Rock Mech. Geotech. Eng. 2, 2, 97–102, DOI: 10.3724/SP.J.1235.2010.00097.

Hunt, J.M. (1996), Petroleum Geochemistry and Geology, 2nd ed., W.H. Freeman and Co., New York, 100 pp.

Laloui, L., and C. Cekerevac (2003), Thermo-plasticity of clays an isotropic yield mechanism, Comp. Geotech. 30, 8, 649–660, DOI: 10.1016/j.compgeo. 2003.09.001.

Lee, S., Y.J. Kim, and H.S. Moon (1999), Phase transformation sequence from kaolinite to mullite investigated by an energy-filtering transmission electron microscope, J. Am. Ceram. Soc. 82, 10, 2841–2848, DOI: 10.1111/j.1151-2916.1999.tb02165.x.

Li, Y., Q.C. Yu, B. Yang, and Y. Dai (2012), Characterization of vacuum thermal decomposed kaolin vacuum, Chin. J. Vacuum Sci. Tech. 32, 599–604 (in Chinese).

Mao, R.R., X.B. Mao, L.Y. Zhang, and R.X. Liu (2015), Effect of loading rates on the characteristics of thermal damage for mudstone under different temperatures, Int. J. Min. Sci. Technol. 25, 5, 797–801, DOI: 10.1016/j.ijmst. 2015.07.015

Melenevsky, V.N., A.E. Kontorovich, and W.L. Huang, A.I. Larichev, and T.A. Bul’bak (2009), Hydrothermal pyrolysis of organic matter in Riphean mudstone, Geochem. Int. 47, 5, 476–484, DOI: 10.1134/ S0016702909050048.

Monfared, M., J. Sulem, P. Delage, and M. Mohajerani (2011), A laboratory investigation on thermal properties of the opalinus claystone, Rock Mech. Rock Eng. 97, 735–747, DOI: 10.1007/s00603-0110-0171-4.

Nelskamp, S., P. David, and R. Littke (2008), A comparison of burial, maturity and temperature histories of selected wells from sedimentary basins in the Netherlands, Int. J. Earth Sci. 97, 5, 931–953, DOI: 10:1007/s00531-007-0229-4.

O’Flaherty, C.A., and M.N. Gray (1974), The influence of alkali compounds on the compaction and early strength properties of lime-soil mixtures, Austral. Road Res. 5, 5, 4–15.

Peltonen, C., Ø. Marcussen, Bjørlykke, and J. Jahren (2009), Clay mineral diagenesis and quartz cementation in mudstones: The effects of smectite to illite reaction on rock properties, Mar. Petrol. Geol. 26, 6, 887–898, DOI: 10.1016/j.marpelgeo.2008.01.021.

Radhokrishra, H.S., and H.T. Chan (1989), Thermal and physical properties of candidate buffer-backfill material for a nuclear fuel waste disposal vault, Can. Geotech. 26, 6, 629–639, DOI: 10.1016/0148-9062(90)92830-8.

Sánchez, M., A. Shastri, and A. Gens (2011), Transient behavior of a clay barrier subjected to high temperature changes, Geo-Frontiers 2011, 4156–4165, DOI: 10.1061/41165(397)425.

Sato, T., T. Watanable, and Otsuka (1992), Effects of layer charge location and energy change on expansion properties of dioctahedral smectite, Clay. Clay Miner. 40, 1, 103–113, DOI: 10.1346/CCMN.1992.0400111.

Ślizowski, K., J. Janeczek, and K. Przewłocki (2003), Suitability of salt-mudstones as a host rock in salt domes for radioactive-waste storage, Appl. Energ. 75, 1-2, 119–128, DOI: 10.1016/S0140-6701(04)91754-7.

Sun, L.N., Z.N. Zhang, Y.D. Wu, L. Su, Y.Q. Xia, Z.D. Gao, Y.W. Zheng, and Z.X. Wang (2015a), Effect of temperature and pressure on hydrocarbon yield of source rock HTHP simulation experiment in semi-open system, Nat. Gas. Geosci. 26, 1, 118–127, DOI: 10.11764/j.issn.1672-1926.2015.01. 0118 (in Chinese).

Sun, Q., S.Y. Zhu, and L. Xue (2015b), Electrical resistivity variation in uniaxial rock compression, Arab. J. Geosci. 8, 4, 1869–1880, DOI: 10.1007/s12517-014-1381-3.

Sundberg, J., P.E. Back, R. Christiansson, H. Hökmark, M. Ländell, and J. Wrafter (2009), Modeling of thermal rock mass properties at the potential sites of a Swedish nuclear waste repository, Int. J. Rock Mech. Min. Sci. 46, 6, 1042–1054, DOI: 10.1016/j.ijrmms.2009.02.004.

Tian, H., M. Ziegler, and T. Kempka (2014), Physical and mechanical behavior of claystone exposed to temperatures up to 1000°C, Int. J. Rock Mech. Min. Sci. 70, 144–153, DOI: 10.1016/j.ijrmms.2014.04.014.

Witherspoon, P.A. (2001), Geological Challenges in Radioactive Waste Isolation, Third Word Rev., California, USA.

Wu, J.G., and H.W. Zhou (2008), Dynamic experimental research on phase transformation of Kaoliniteiteunder high temperature within microzone, Nonmetallic. Min. 31, 6, 10–13, DOI: 10.1016/j.clay.2013.07.017 (in Chinese).

Zhang, L.Y. (2012), Research on damage evolution and fracture mechanisms of mudstone under high temperature, Ph.D. Thesis, China. Univ. Min. Tech., Xuzhou (in Chinese).

Zhang, Z.Q., and R.Z. Yuan (1993), Study on dchydroxylation process of Kaolinite and its structural change, Bull. Chin. Ceramic Soc. 4, 37–41 (in Chinese).

Zheng, J.D., B.B. Chang, T.T. Chen, and J. Yin (2010), Study on the high temperature modification of attapulgite, Appl. Chem. Industry 39, 1835–1837 (in Chinese).

Zhu, H.J., X. Yao, and Z.H. Zhang (2008), Optimization of calcined temperature for Kaolinite activation, J. Build. Mater. 1, 621–625 (in Chinese).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

This is an open access article distributed under the Creative Commons Attribution-NonCommercial-NoDerivs license, http://creativecommons.org/licenses/by-nc-nd/3.0/.

About this article

Cite this article

Sun, Q., Zhang, W., Zhang, Y. et al. Variations of Strength, Resistivity and Thermal Parameters of Clay after High Temperature Treatment. Acta Geophys. 64, 2077–2091 (2016). https://doi.org/10.1515/acgeo-2016-0090

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1515/acgeo-2016-0090