Abstract

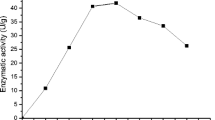

A newly isolated mesophilic bacterial strain from dahlia rhizosphere, identified as Staphylococcus sp. and designated as RRL-M-5, was evaluated for inulinase synthesis in submerged cultivation using different carbon sources individually or in combination with inulin as substrate. Inulin appeared as the most favorable substrate at a 0.5–1.0% concentration. Media pH influenced the enzyme synthesis by the bacterial strain, which showed an optimum pH at 7.0–7.5. Supplementation of fermentation medium with external nitrogen (organic and inorganic) showed a mixed impact on bacterial activity of enzyme synthesis. The addition of soybean meal and corn steep solid resulted in about an 11% increase in enzyme titers. Among inorganic nitrogen sources, ammonium sulfate was found to be the most suitable. Maximum enzyme activities (446 U/L) were obtained when fermentation was carried out at 30°C for 24 h with a medium containing 0.5% inulin as a sole carbon source and 0.5% soybean meal as the nitrogen source. Bacterial inulinase could be a good source for the hydrolysis of inulin for the production of d-fructose.

Similar content being viewed by others

References

Vandamme, E. J. and Derycke, D. G. (1983), Adv. Appl. Microbiol. 29, 139–176.

Pandey, A., Soccol, C. R., Selvakumar, P., Soccol, V. T., Krieger, N., and Fontana, J. D. (1999), Appl. Biochem. Biotechnol. 81(1), 35–52.

Duvnjak, Z., Kosaric, N., and Hayes, R. D. (1981), Biotechnol. Lett. 3, 589–594.

Favela-Torres, E., Allais, J. J., and Barratti, J. (1986), Biotechnol. Bioeng. 18, 850–856.

Ohta, K., Hamada, S., and Nakamura, T. (1993), Appl. Environ. Microbiol. 59, 729–733.

Margaritis, A., Merchant, F. J. A., and Veliky, I. A. (1983), Biotechnol. Lett. 5, 271–276.

Grootwassink, H. W. D. and Hewit, G. M. (1983), J. Gen. Microbiol. 129, 31–41.

Ongen-Baysal, G. and Sukan, S. S. (1996), Biotechnol. Lett. 18, 1431–1434.

Selvakumar, P. and Pandey, A. (1999), Biores. Technol. 69(2), 123–127.

Negoro, H. and Kito, E. (1973), J. Ferment. Technol. 51, 96–102.

Beluche, I., Guiraud, J. P., and Galzy, P. (1980), Folia Microbiol. 25, 32–39.

Nakamura, T., Shitara, A., Matsuda, S., Matsuo, T., Suiko, M., and Ohta, K. (1997), J. Ferment. Bioeng. 84(4), 313–318.

Nakamura, T., Ogate, Y., Shitara, A., Nakamura, A., and Ohta, K. (1995), J. Ferment. Bioeng. 80, 164–169.

Ettalibi, M. and Barratti, J. C. (1987), Appl. Microbiol. Biotechnol. 26, 13–20.

Kaur, N., Kaur, M., Gupta, A. K., and Singh, R. (1992), J. Chem. Technol. Biotechnol. 53, 279–284.

Xiao, R., Tanida, M., and Takao, S. (1988), J. Ferment. Technol. 66(5), 553–558.

Efstathion, I., Reyset, G., and Truffant, N. (1986), Appl. Microbiol. Biotechnol. 25, 143–149.

Kim, D. H., Choi, Y. J., Song, S. K., and Yun, J. W. (1997), Biotechnol. Lett. 19(4), 369–371.

Baron, M, Florencio, J. A., Zamin, G. M., Ferreira, A. G., Ennes, R., and Fontana, J. D. (1996), Appl. Biochem. Biotechnol. 57–58, 605–615.

Miller, G. L. (1959), Anal. Chem. 31, 426–428.

Lowry, O. H., Rosebrough, N. J., Farr, A. L., and Randall, R. J. (1951), J. Biol. Chem. 193, 265–275.

Passador-Gurgel, G. C., Furian, S. A., Meller, J. K., and Jonas, R. (1996), Appl. Microbiol. Biotechnol. 45, 158–161.

Patent no. PN, JP 7327604, dt. 19.12.1995

Poorna, V. and Kulkarni, P. (1996), Indian J. Microbiol. 36, 117, 118.

Fontana, J. D., Baron, M., Diniz, A. C. P., and Franco, V. C. (1994), Appl. Biochem. Biotechnol. 45–46, 257–268.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Pandey, A., Joseph, S., Ashakumary, L. et al. Inulinase synthesis from a mesophilic culture in submerged cultivation. Appl Biochem Biotechnol 82, 103–114 (1999). https://doi.org/10.1385/ABAB:82:2:103

Received:

Revised:

Accepted:

Issue Date:

DOI: https://doi.org/10.1385/ABAB:82:2:103