Abstract

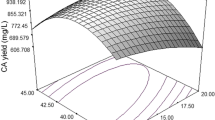

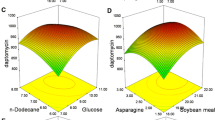

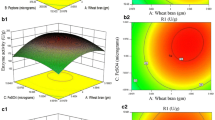

Optimization of the fermentation medium components for maximum gentamicin production by Micromonospora echinospora ATCC 15838 was carried out. Response surface methodology was applied to optimize the medium constituents. A 24full-factorial central composite design was chosen to explain the combined effects of the four medium constituents, viz. starch, soyabean meal, K2HPO4, and CoCl2 and to design a minimum number of experiments. A second order model was developed and fitted using least square method. The R 2 value of the model was 0.9723, which shows that model is best fit for the present studies. The results of analysis of variance and regression of a second order model showed that the linear effects of starch (p<0.001697) and CoCl2(p<7.99E-13), and cross product effects of starch and soyabean meal (p<0.029876) and soyabean meal and CoCl2 (p<0.008909) were more significant, suggesting that these were critical variables having the greatest effect on the production of gentamicin in the production medium. The optimized medium consisting of 9 g/L starch, 3 g/L soyabean meal, 0.9 g/L K2HPO4, and 0.01 g/L CoCL2 predicted 850 mg/L of gentamicin which was almost 110% higher than that of the unoptimized medium. The amounts of starch, soyabean meal, and K2HPO4 required were also reduced with RSM.

Similar content being viewed by others

References

Srinivasulu, B., Prakasam, R. S., Jetty, A., Srinivas, S., Ellaiah, P., Ramakrishna, S. V. (2002), Pro. Biochem. 38, 593–598.

Swaroopa, R. A., Annapurna, J., Ramakrishna, S. V. (2003), Chem. Biochem. Eng. Q. 17, 99–174.

Jetty, A., Rao, A. G., Rao, S. B., Madhavi, G., and Ramakrishna, S. V. (2005), Chem. Biochem. Eng. Q. 19(2), 179–184.

Weinstein, M. J., Luedemann, G. M., Oden, E. M., and Wagman, G. H. (1965), Antimicro. Agents Chemother. 810–820.

Weinstein, M. J., Luedemann, G. M., Oden, E. M., Wagman, G. H., Rosselet, J. P., Marquez, J. A., Coniglio J. A., et al. (1963), J. Med. Chem. 6, 463,464

Abou-zeid, A. A., Abd El-Wahab, I. E., and Salem, H. M. (1974), J. App. Chem. Biotech. 24, 655–661.

Wagman, G. H. and Weinstein, M. J. (1980), Ann. Rev. Microbio., 34, 537–557.

Litovchik, A., Eudokimov, A. G., and Lapidot, A. (1999), FEBS Let 445, 73–79.

Kennedy, M. and Krouse, D. (1999), J. Ind. Microbio. Biotech. 23, 456–475.

Sunitha, I., Subba Rao, M. V., and Ayyanna, C. (1998), Biopro. Eng. 18, 353–359.

Ambati, P. and Ayyanna, C. (2001), World J. Microbio. Biotech. 17, 331–335.

Puri, S., Beg, Q. K., and Gupta, R. (2002), Cur. Microbio. 44, 286–290.

Ismail Hakki Boyaci. (2005), Biochem. Eng. J. 25, 55–62.

Adinaryana, K., Ellaiah, P., Srinivasulu, B., Bhavani Devi, R., and Adinarayana, G. (2003), Pro. Biochem 38, 1565–1572.

Adinarayana, K. and Suren, S. (2005), Biochem. Eng. J. 27, 179–190.

Murat, E. (2004), Pro. Biochem. 39, 1057–1062.

Himabindu, M., and Jetty, A. (2005), World J Micrbio. Biotech. (communication number WIBI-S-05-00793).

Sanchez, S., Mateos, R. C., Paniagua, L., Lara, F., and Mora, J. (1981), in Fermentation products (Young, M. M. and Venzina, C., eds.), Pergamon Press, Toronto, pp. 147–154.

Loewus, F. A. (1952), Anal. Chem. 24, 219.

Bayraktar, E. (2001), Pro. Biochem. 37, 169–175.

Myers, R. H. and Montgomery, D. C. (1995), Response Surface Methodology: Process and Product Optimization Using Designed Experiments, 1st ed. Wiley-Interscience, New York.

Khuri, A. I. and Cornell J. A (1987), Response Surfaces: Design and Analysis, New York.

Box, G. E. P., Hunter, W. G., and Hunter, J. S. (1978), in Statistics for experimenters (John Wiley and Sons), New York, pp. 291–334.

Cochran, W. G. and Cox, G. M. (1957), in Experimental design, 2nd ed. (John Wiley and Sons), New York, pp. 346–354.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Himabindu, M., Ravichandra, P., Vishalakshi, K. et al. Optimization of critical medium components for the maximal production of gentamicin by Micromonospora echinospora ATCC 15838 using response surface methodology. Appl Biochem Biotechnol 134, 143–154 (2006). https://doi.org/10.1385/ABAB:134:2:143

Received:

Revised:

Accepted:

Issue Date:

DOI: https://doi.org/10.1385/ABAB:134:2:143