Abstract

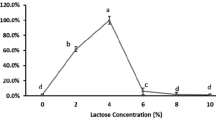

The culture medium for Streptomyces lavendulae ATCC 13664 was optimized on a shake-flask scale by using a statistical factorial design for enhanced production of penicillin acylalse. This extracellularenzyme recently has been reported to bea penicillin Kacylase, presenting also high hydrolytic activity against penicillin V and other natural aliphatic penicillins such as penicillin K, penicillin F, and penicillin dihydroF,. The factorial design indicated that the main factors that positively affect penicillin acylase production by S. lavendulae were the concentration of yeast extract and the presence of oligoelements in the fermentation medium, whereas the presence of olive oil in the medium had no effect on enzyme production. An initial concentration of 2.5% (w/v) yeast extract and 3 μg/mL of CuSO4·5H2O was found to be best for acylase production. In such optimized culture medium, fermentation, of the microorganism yielded 289 IU/L of enzyme in 72 h when employing a volume medium/volume flask ratio of 0.4 and a 300-rpm shaking speed. The presence of copper, alone and in combination with other metals, stimulated biomass as well as penicillin acylase production. The time course of penicillin acylase production was also studied in the optimized medium and conditions. Enzyme production showed catabolite repression by different carbon sources such as glucose, lactose, citrate, glycerol, and glycine.

Similar content being viewed by others

References

Arroyo, M., de la Mata, I., Acebal, C., and Castillón, M. P. (2003), Appl. Microbiol. Biotechnol. 60, 507–514.

Shewale, J. G. and Sudhakaran, V. K. (1997), Enzyme Microb. Technol. 20, 402–410.

Torres, R., Ramón, F., de la Mata, I., Acebal, C., and Castillón, M. P. (1999), Appl. Microbiol. Biotechnol. 53, 81–84.

Torres-Guzmán, R., de la Mata, I., Torres-Bacete, J., Arroyo, M., Castillón, M. P., and Acebal, C. (2002), Biochem. Biophys. Res. Commun. 291, 593–597.

Sio, C. F. and Quax, W. J. (2004), Curr. Opin. Biotechnol. 15, 349–355.

Junqua, M., Duran, R., Gancet, C., and Goulas, P. (1997), Appl. Microbiol. Biotechnol. 48, 730–734.

Gawande, B. N., Singh, R. K., Chauhan, A. K., Goel, A., and Patkar, A. Y. (1998), Enzyme Microb. Technol. 22, 288–291.

Sunitha, K., Kim, Y.-O., Lee, J.-K., and Oh, T.-K. (2000), Biochem. Eng. J. 5, 51–56.

Seth, M. and Chand, S. (2000), Process Biochem. 36, 39–44.

Kalil, S. J., Suzan, R., Maugeri, F., and Rodrigues, M. I. (2001), Appl. Biochem. Biotechnol. 94, 257–264.

Abdel-Fattah, Y. R. and Olama, Z. A. (2002), Process Biochem. 38, 115–122.

Chen, Q.-H., He, G.-Q., and Ali, M. A. M. (2002), Enzyme Microb. Technol. 30, 667–672.

Burket, J. F. M., Maugeri, F., and Rodriguez, M. I. (2004), Bioresour. Technol. 91, 77–84.

Tang, X.-J., He, G.-Q., Chen, Q.-H., Zhang, X.-Y., and Ali, M. A. M. (2004), Bioresour. Technol. 93, 175–181.

Bradford, M. H. (1976), Anal. Biochem. 72, 248–274.

Haaland, P. D. (1989), Experimental Design in Biotechnology, Marcel Dekker, New York.

Sudhakran, V. K. and Shewale, J. G. (1990), J. Microb. Biotechnol. 5, 66–74.

Chauhan, S., Iyengar, M. R. S., and Chattoo, B. B. (1998), J. Basic Microbiol. 38, 173–179.

Vandamme, E. J. and Voets, J. P. (1975), Experientia 31, 140–143.

Carlsen, F. and Emborg, C. (1981), Biotechnol. Lett. 3, 375–378.

Stoppock, E. and Wagner, F. (1983), Biotechnol. Lett. 8, 503–508.

Kieser, T. and Hopwood, D. A. (1991), Methods Enzymol. 294, 430–458.

Ueda, K., Endo, K., Tacaño, H., Nishimoto, M., Kido, Y., Tomaru, Y., Matsuda, K., and Beppu, T. (2000), Antonie van Leeuwenhoek 78, 263–268.

Dionigi, C. P., Ahten, T. S., and Wartelle, L. H. (1996), J. Ind. Microbiol. 17, 84–88.

Coelho, R. R. and Linhares, L. F. (1993), Biol. Fertil. Soils 15, 220–224.

Mason, H. S. (1965), Annu. Rev. Biochem. 34, 595–634.

Lerch, K. (1981), in Metal Ions in Biological Systems, vol. 13, Siegel, H., ed., Marcel Dekker, New York, pp. 143–186.

Tsai, T.-Y. and Lee, Y.-H. W. (1998), J. Biol. Chem. 273, 19,243–19,250.

Jones, A. M. and Porter, M. A. (1998), J. Ind. Microbiol. Biotechnol. 21, 203–207.

Junker, B., Mann, Z., Gailiot, P., Byrne, K., and Wilson, J. (1998), Biotechnol. Bioeng. 5, 580–588.

Arroyo, M., Torres, R., de la Mata, I., Castillón, M. P., and Acebal, C. (1999), Enzyme Microb. Technol. 25, 378–383.

Arroyo, M., Torres, R., de la Mata, I., Castillón, M. P., and Acebal, C. (2000), Enzyme Microb. Technol. 27, 122–126.

Arroyo, M., Torres-Guzmán, R., de la Mata, I., Castillón, M. P., and Acebal, C. (2000), Biotechnol. Prog. 16, 368–371.

Torres-Bacete, J., Arroyo, M., Torres-Guzmán, R., de la Mata, I., Castillón, M. P., and Acebal, C. (2000), Biotechnol. Lett. 22, 1011–1014.

Torres-Bacete, J., Arroyo, M., Torres-Guzmán, R., de la Mata, I., Castillón, M. P., and Acebal, C. (2000), Biotechnol. Appl. Biochem. 32, 173–177.

Torres-Bacete, J., Arroyo, M., Torres-Guzmán, R., de la, Mata, I., Castillón, M. P., and Acebal, C. (2001), J. Chem. Technol. Biotechnol. 76, 525–528.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Torres-Bacete, J., Arroyo, M., Torres-Guzmán, R. et al. Optimization of culture medium and conditions for penicillin acylase production by streptomyces lavendulae ATCC 13664. Appl Biochem Biotechnol 126, 119–131 (2005). https://doi.org/10.1385/ABAB:126:2:119

Received:

Revised:

Accepted:

Issue Date:

DOI: https://doi.org/10.1385/ABAB:126:2:119