Abstract

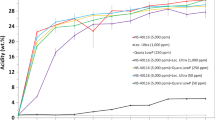

This article reports experimental data on the production of fatty acid ethyl esters from refined and degummed soybean oil and castor oil using NaOH as catalyst. The variables investigated were temperature (30–70°C), reaction time (1–3 h), catalyst concentration (0.5–1.5 w/wt%), and oil-to-ethanol molar ratio (1:3–1:9). The effects of process variables on the reaction conversion as well as the optimum experimental conditions are presented. The results show that conversions >95% were achieved for all systems investigated. In general, an increase in reaction temperature, reaction time, and in oil-to-ethanol molar ratio led to an enhancement in reaction conversion, whereas an opposite trend was verified with respect to catalyst concentration.

Similar content being viewed by others

References

Fukuda, H., Kondo, A., and Noda, H. (2001), J. Biosci. Bioeng. 92, 405–416.

Ma, F. and Hanna, M. A. (1999), Bioresour. Technol. 70, 1–15.

Srivastava, A. and Prasad, R. (2000), Renewable Sustainable Energy Rev. 4, 111–133.

Altin, R., Çetinkaya, S., and Yucesu, H. S. (2001), Energy Conversion Manage. 42, 529–538.

Zhang, Y., Dubé, M. A., McLean, D. D., and Kates, M. (2003), Bioresour. Technol. 89, 1–16.

McCormick, R. L., Graboski, M. S., Alleman, T. L., and Herring, A. M. (2001), Environ. Sci. Technol. 35, 1742–1747.

Al Saadi, A. N. and Jeffreys, G. V. (1981), AIChE J. 27, 754–772.

Iso, M., Chen, B., Eguchi, M., Kudo, T., and Shrestha, S. (2001), J. Mol. Catal. B 16, 53–58.

Wright, H. J., Segur, J. B., Clarck, H. V., Coburn, S. K., Langdon, E. E., and DuPuis, R. N. (1944), Oil Soap 21, 145–148.

Ma, F., Clements, L. D., and Hanna, M. A. (1998), Trans. ASAE 41, 1261–1264.

Alcantara, R., Amores, J., Canoira, L., Fidalgo, E., Franco, M. J., and Navarro, A. (2000), Biomass Bioenergy 18, 515–527.

Freedman, B., Pryde, E. H., and Mounts, T. L. (1984), J. Am. Oil Chem. Soc. 61, 1638–1643.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

de Oliveira, D., Di Luccio, M., Faccio, C. et al. Optimization of alkaline transesterification of soybean oil and castor oil for biodiesel production. Appl Biochem Biotechnol 122, 553–560 (2005). https://doi.org/10.1385/ABAB:122:1-3:0553

Issue Date:

DOI: https://doi.org/10.1385/ABAB:122:1-3:0553