Abstract

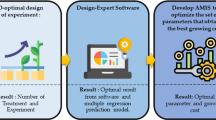

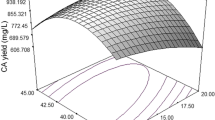

This article presents the optimization of gallic acid production using filamentous fungi from tannin-rich mixed substrates taking into account the interaction effects of six variable process parameters. The methodology adopted for optimization was the evolutionary operation (EVOP)-factorial design technique. This technique combines the factorial method for designing experiments with the EVOP methodology for analyzing the experimental results systematically and arriving at conclusions according to its decision-making procedure. Standard deviation and error limits based on 95% confidence were calculated according to the relationship given in the literature. It was found that the best combinations of the process parameters at the optimum levels were 30°C, 80% relative humidity, pH 5.0, 48-h incubation period, 3 mL of induced inoculum, and 35 g of mixed substrate, resulting in a gallic acid yield of 94.8% under modified solid-state fermentation.

Similar content being viewed by others

References

Kennedy, M. and Krouse, D. (1999), J. Ind. Microbiol. Biotechnol. 23, 456–475.

Fisher, R. A. (1926), J. Min. Agric. 33, 503–513.

Lekha, P. K. and Lonsane, B. K. (1997), Adv. Appl. Microbiol. 44, 215–260.

Hadi, T. A., Banerjee, R., and Bhattacharyya, B. C. (1994), Bioprocess Eng. 11, 239–243.

Kar, B., Banerjee, R., and Bhattacharyya, B. C. (1999), J. Ind. Microbiol. Biotechnol. 23, 173–177.

Mukherjee, G. and Banerjee, R. (2003), Chem. Today 21(1/2), 59–62.

Pandey, A., Selvakumar, P., Soccol, C. R., and Nigam, P. (1999), Curr. Sci. 77(1), 149–162.

Banerjee, R. and Bhattacharyya, B. C. (1993), Biotechnol. Bioeng. 41, 67–71.

Tunga, R., Banerjee, R., and Bhattacharyya, B. C. (1999), J. Biosci. Bioeng. 87, 125–131.

Davis, O. L. (1954), in Design and Analysis of Industrial Experiments, Hafner, New York, pp. 440–480.

Adler, Y. P., Markos, E. V., and Granovsky, Y. V. (1975), in The Design of Experiments to Find Optimal Conditions, Mir Publishers, Moscow, pp. 118–144.

Box, G. E. P. and Hunter, J. S. (1959), Technometric 1, 77–95.

Pearson, E. S. and Hartley, H. O. (1962), in Biometrika Tables for Statisticians Vol. 1 (2nd ed.), University Press, Cambridge, UK, p. 46.

Adler, Y. P. and Granovsky, Y. V. (1972), A Review of Applied Studies by Experimental Design, Reprint No. 33 (2nd ed.), LSM, Moscow State University, Moscow.

Banerjee, R. and Bhattacharyya, B. C. (2003), Biochem. Eng. J. 13, 149–155.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mukherjee, G., Banerjee, R. Evolutionary operation-factorial design technique for optimization of conversion of mixed agroproducts into gallic acid. Appl Biochem Biotechnol 118, 33–46 (2004). https://doi.org/10.1385/ABAB:118:1-3:033

Received:

Revised:

Accepted:

Issue Date:

DOI: https://doi.org/10.1385/ABAB:118:1-3:033