Abstract

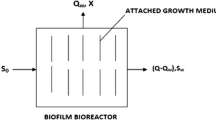

Mass transfer within microbial films was described using Monod-type biological kinetics in terms of properties of filter media and feed solution. The performance characteristics of a trickling filter were thus modeled. The model enables one to consider the effect of inlet substrate concentration and flow rate upon the removal efficiency. For this purpose a second-order partial differential equation describing the dispersion phenomena inside the liquid layer was solved under special boundary conditions and used to determine substrate flux into the biofilm. A uniform biofilm thickness was considered. The model is based on computer techniques and the numerical evaluation of the normalized biofilm mathematical model. A design procedure was also given to calculate biological filters. The numerical model was also applied to experimental data to demonstrate its validity.

Similar content being viewed by others

Abbreviations

- a :

-

radius of sphere, L

- A :

-

cross sectional area, L2

- B s :

-

dimensionless substrate concentration at liquid biofilm interface

- C :

-

dimensionless substrate concentration defined as c/c i

- C x :

-

dimensionless concentration defined as c x/c i

- c :

-

bulk substrate concentration, M L−3

- c x :

-

substrate concentration at any location in liquid phase, M L−3

- c f :

-

substrate concentration within biofilm, M L−3

- D c :

-

the diffusivity of substrate in the biofilm, L2 T−1

- D w :

-

molecular diffusivity of substrate in liquid, L2 T−1

- h :

-

liquid film thickness, L

- K :

-

dimensionless ratio of mass transfer rate to kinetic rate

- K s :

-

Monod-half velocity coefficient, M L−3

- k :

-

maximum utilization rate of rate limiting substrate, T−1

- k1=kXc/Ks:

-

a biological rate equation coefficient, T−1

- k2=(k1/Dc)1/2:

-

a coefficient related to a solid phase diffusional limitation, L−1

- k3=1/Ks:

-

a biological rate equation coefficient, M−1 L−3

- L :

-

microbial film thickness, L

- l :

-

dimensional filter length, L

- M :

-

dimensionless biofilm thickness

- N :

-

substrate flux, M L−2 T−1

- q :

-

flow rate per unit width of the biofilm, L3T−1 L−1

- Q :

-

volumetric flow rate, L3 T−1

- Q A :

-

hydraulic loading rate, L3 T−1 L−2

- S :

-

specific surface area, L2 L−3

- w av :

-

average velocity of liquid in z direction, L T−1

- w max :

-

maximum velocity at the liquid surface, L T−1

- X c :

-

microbial density within biofilm, M L−3

- x :

-

distance measured normal to the flow direction, L

- z :

-

axial distance measured in flow direction from origin, L

- α:

-

dimensionless filter length

- γ:

-

liquid specific gravity, M L−2 T−2

- η:

-

biological removal ratio = biological efficiency

- ηD = ξ/D w h :

-

a parameter to express Cx as a function of ZD and X

- μ:

-

dynamic viscosity, M L−1 T−1

- Ω:

-

proportionality constant to express wetting rate, dimensionless

- ξ:

-

a proportionality factor in Eq. 1, L T−1

References

Atkinson, B. and Daoud, I. S. (1970), Trans. Inst. Chem. Engrs. 48, 245–254.

Atkinson, B. and Williams, D. A. (1971), Trans. Inst. Chem. Engrs. 49, 215–224.

Atkinson, B. and Davies, I. J. (1974), Trans. Inst. Chem. Engrs. 52, 248–259.

Atkinson, B. and How, S. Y. (1974), Trans. Inst. Chem. Engrs. 52, 260–268.

Atkinson, B. and Abdel Rahman Ali, M. E. (1976), Water Res. 12, 147–156.

Crine, M., Schlitz, M., and Vandevenne, L. (1991), Chem. Eng. J. 46, B59-B68.

Hinson, X. and Kocher, Y. (1996), J. Environ. Engrg. ASCE 122(11), 1023–1030.

Muslu, Y. (1983), Water Res. 17(1), 105–115.

Muslu, Y. and Sansarcı, H. (1983), Calculation of substrate removal efficiency in biological filters using a numerical approach (in Turkish), Çevre 83 Sempozyumu, Dokuzeylul Üniv. Muh. Mim. Fak., Bornova, Izmir, Turkey.

Muslu, Y. (1984), J. Environ. Engrg. ASCE 110(5), 961–975.

Muslu Y. and Ürun H. (1986), ITU Dergisi 44(1–2), 43–48.

Muslu, Y. (1993), J. Chem. Tech. Biotech. 57(2), 127–135.

Muslu, Y. (1995), J. Environ. Engrg. ASCE 121(1), 66–83.

Parker, D. S. (1999), J. Environ. Engrg: ASCE 125(7), 618–625.

Rittman, B. E. and McCarty, P. L. (1981), J. Environ. Engrg. Div. ASCE 107(4), 889–900.

Sekerdag, N. and Muslu, Y. (1986), One dimensional dispersion in biological filters, Part II (in Turkish). Doga TU Müh. Ve Çev. D. (TÜB_TAK), Ankara, Turkey, 10(3), 298–307.

Suidan, M. T. (1986), J. Environ. Engrg. ASCE 112(1), 78–93.

Suidan, M. T., Rittman, B. E., and Traegner, U. K. (1987), Water Res. 21(4), 491–498.

Williamson, K. and McCarty, P. L. (1976), J. Water Pollution Control Fed. 48(1), 9–24.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Muslu, Y. Significance of fluid regime and wetted area in biofilm reactors. Appl Biochem Biotechnol 101, 177–195 (2002). https://doi.org/10.1385/ABAB:101:3:177

Received:

Revised:

Accepted:

Issue Date:

DOI: https://doi.org/10.1385/ABAB:101:3:177