Abstract

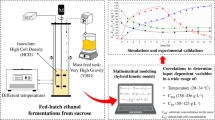

To optimize the fed-batch processes of glycerol fermentation in different reactor states, typical bioreactors including 500-mL shaking flask, 600-mL and 15-L airlift loop reactor, and 5-L stirred vessel were investigated. It was found that by reestimating the values of only two variable kinetic parameters associated with physical transport phenomena in a reactor, the macrokinetic model of glycerol fermentation proposed in previous work could describe well the batch processes in different reactor states. This variable kinetic parameter (VKP) approach was further applied to model-based optimization of discrete-pulse feed (DPF) strategies of both glucose and corn steep slurry for glycerol fed-batch fermentation. The experimental results showed that, compared with the feed strategies determined just by limited experimental optimization in previous work, the DPF strategies with VKPs adjusted could improve glycerol productivity at least by 27% in the scale-down and scale-up reactor states. The approach proposed appeared promising for further modeling and optimization of glycerol fermentation or the similar bioprocesses in larger scales.

Similar content being viewed by others

References

Zhuge, J. and Fang, H. Y. (1994), Food Ferment. Ind. (China) 4, 65–70.

Xie, D.-M. (2000), PhD thesis. Institute of Chemical Metallurgy, Chinese Academy of Sciences, Beijing, P. R. China.

Fan, Z.-L. (1996), MSc thesis, Institute of Chemical Metallurgy, Chinese Academy of Sciences, Beijing, P. R. China.

Sun, H.-W. (1997), MSc thesis, Institute of Chemical Metallurgy, Chinese Academy of Sciences, Beijing, P. R. China.

Yang, Y.-O. (1999), MSc thesis, Institute of Chemical Metallurgy, Chinese Academy of Sciences, Beijing, P. R. China.

Vijaikshore, P. and Karanth N. G. (1987), Biotechnol. Bioeng. 30, 325–328.

Johnson, A. (1987) Automatica 23(6), 691–705.

Modak, J. M., Lim, H. C., and Tayeb, Y. J. (1986), Biotechnol. Bioeng. 28, 1396–1407.

Lim, H. C., Tayeb, Y. J., and Modak, J. M. (1986), Biotechnol. Bioeng. 28, 1408–1420.

Xie, D.-M., Liu, D.-H., Zhu, H.-L., and Liu, T.-Z. (2001), Appl. Biochem. Biotechnol. 95, 103–112.

Moser, A. (1988), Bioprocess Technology: Kinetics and Reactors (translated by Manor, P.), Springer, New York.

Gill, P. E. and Murray, W. (1974), in Numerical Methods for Constrained Optimization, Academic, New York.

Ye, Q.-K. and Wang, Z. M. (1986) Computational Methods for Optimization and Optimal Control, Science Press, Beijing, Chap. 7, pp. 233–271.

Box, M. J. (1965), Comput. J. 8, 42–52.

Xu, S.-L. (1997), in Collection of QBASIC Programs for Numerical Computation, Tsinghua University Press, Beijing, Chap. 12, pp. 402–407, 420–427.

Sahoo, D. K. and Agarwal, G. P. (2001), Process Biochem. 36, 839–846.

Neish, A. C. (1954), Analytical Methods for Bacterial Fermentation 2nd rev., Bulletin no. 25292, National Research Council of Canada, Ottawa, Canada.

Ashworth, M. F. R. (1979), Analytical Methods for Glycerol, Academic, New York.

Murphy, J. and Riley, J. P. (1962), Anal. Chim. Acta. 27, 31–36.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xie, D., Liu, D., Zhu, H. et al. Optimization of glycerol fed-batch fermentation in different reactor states. Appl Biochem Biotechnol 101, 131–151 (2002). https://doi.org/10.1385/ABAB:101:2:131

Received:

Revised:

Accepted:

Issue Date:

DOI: https://doi.org/10.1385/ABAB:101:2:131