Abstract

An aero engine failed due to the misalignment of the ball bearing fitted on the main shaft of the engine.

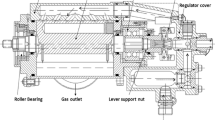

The aero engine incorporates two independent compressors: a six-stage axial flow low-pressure compressor and a nine-stage axial flow high-pressure compressor. The bearing under consideration is a high-pressure-location bearing and is fitted at the rear of the nine-stage compressor. It was supposed to operate for at least 5000 h but failed catastrophically after 1300 h of operation and rendered the engine unserviceable.

Unusually high stresses caused by misalignment and uneven axial loading resulted in the generation of fatigue crack(s) in the inner race. When the crack reached the critical size, the collar of the race fractured, causing subsequent damage. The cage also failed due to excessive stresses in the axial direction, and its material was smeared on the steel balls and the outer race.

Similar content being viewed by others

References

W.F. Smith:The Structure and Properties of Engineering Alloys, 2nd ed., McGraw-Hill, 1986, pp. 40–45.

Metallography and Microstructures, vol. 9,Metals Handbook, 9th ed., American Society for Metals, 1985, pp. 264, 412.

Properties and Selection: Stainless. Steels, Tool Materials, and Special-Purpose Metals, vol. 3,Metals Handbook, 9th ed., American Society for Metals, 1980, pp. 425–426.

Failure Analysis and Prevention, vol. 11,Metals Handbook, 9th ed., American Society for Metals, 1986, pp. 490–495, 506–507.

Eng. Fail. Anal., 1998,5(4), pp. 261–269.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ejaz, N., Salam, I. & Tauqir, A. Failure analysis of an aero engine ball bearing. J Fail. Anal. and Preven. 6, 25–31 (2006). https://doi.org/10.1361/154770206X156240

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1361/154770206X156240