Abstract

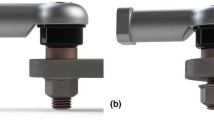

Following the deaths of three people involved in a vehicular collision with an ejected horse, criminal charges were brought against the horse’s owner. Failure analysis was performed on the horse’s trailer to determine its roadworthiness. The failure mode of the hinge between the door and frame became the focus of the investigation. The analysis concentrated on proving whether or not the hinge was broken prior to the collision; that the trailer was not roadworthy; and whether the trailer was capable of safely transporting two horses on a public freeway. Analysis using optical microscopy and the scanning electron microscope indicated the hinge was significantly corroded and mechanically deformed. Additionally, there was evidence of paint on an alleged fresh fracture surface. The results were presented at the trial of the defendant.

Similar content being viewed by others

References

Trial testimony of coroner, San Luis Obispo, CA, Mar 2004.

J. Dinse et al.: “Criminal or Gross Negligence—Defined,” California Jury Instructions, Criminal, Section 3.36, 7th ed., 2005.

S. Peterson: Personal interview, California Highway Patrol, San Luis Obispo, CA, Dec 2003.

D. Linnens: Personal interview, California Highway Patrol, San Luis Obispo, CA, Dec 2003.

N. Nguyen et al.: The Effect of Undercut and Residual Stresses on Fatigue Behaviour of Misaligned Butt Joints,” Eng. Fract. Mech., Oct 1996, 55(3), pp. 453–69.

J.B. Wintle et al.: “Technical Failure Investigation of Welded Structures (or How to Get the Most out of Failures),” Eng. Fail. Anal., Dec 2005, 12(6), pp. 1027–37.

Chap. 8 and 23, Principles of Industrial Welding, James F. Lincoln Arc Welding Foundation, Cleveland, OH, 1978.

T. Talkan et al.: Modeling of Paint Flow Rate Flux for Circular Paint Sprays by Using Experimental Paint Thickness Distribution,” Mech. Res. Commun., Sep–Oct 1999, 26(5), pp. 609–17.

W.B. Chen et al.: Development of Al-Containing Zinc-Rich Paints for Corrosion Resistance,” Appl. Surf. Sci., Feb 2002, 187(1–2), pp. 154–64.

F. Tiarks et al.: “Formulation Effects on the Distribution of Pigment Particles in Paints,” Prog. Org. Coatings, Dec 2003, 48(2–4), pp. 140–52.

B. Davidson: Personal interview, Cuesta College Automotive Technology Department, San Luis Obispo, CA, June 2004.

P. Micheli: Understanding How a Spray Gun Atomizes Paint, ” Met. Finish., Oct 2003, 101(10), pp. 59–64.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Niebuhr, D.V. Metallurgical failure analysis of a horse trailer: A criminal investigation. J Fail. Anal. and Preven. 6, 11–16 (2006). https://doi.org/10.1361/154770206X117513

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1361/154770206X117513