Abstract

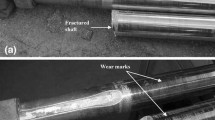

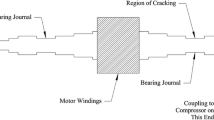

The failure of a high-speed pinion shaft from a marine diesel engine was investigated. The shaft, which had been in service for more than 30 years, failed shortly after a service operation in which the bearings were replaced. Examination of the shaft revealed cyclic fatigue as the failure mechanism, with a substantial distribution of nonmetallic inclusions near the fracture initiation site. Fracture mechanics analysis indicated that the inclusions would be unlikely to have served as failure initiation sites if only stresses acting on the shaft were induced by normal service loads. Further examination of the bearing elements revealed an abnormal wear pattern, consistent with the application of elevated bending loads to the shaft after bearing replacement. The root cause of failure was determined to be an increase in service stresses after bearing replacement along with the presence of significant nonmetallic inclusions in the pinion shaft.

Similar content being viewed by others

References

H. Chandler: Heat Treater’s Guide: Practices and Procedures for Irons and Steels, 2nd ed., ASM International, Materials Park, OH, 1995.

R.W. Hertzberg: Deformation and Fracture Mechanics of Engineering Materials, 4th ed., John Wiley & Sons, Inc., New York, NY, 1995.

R.C. Bates and W.G. Clark: “Fractography and Fracture Mechanics,” Trans. Am. Soc. Met., June 1969, 62, pp. 380–89.

R.L. Boring, G.M. Davidson, A. Hammel, S.D. Henry, S.R. Lampman, F. Reidenback, and W.W. Scott, Jr., ed.: Fatigue and Fracture, vol. 19, ASM Handbook, ASM International, Materials Park, OH, 1996.

G.R. Irwin, P.C. Paris, and H. Tada: The Stress Analysis of Cracks Handbook, 3rd ed., The American Society of Mechanical Engineers, New York, NY, 2000.

H.E. Boyer, ed.: Atlas of Fatigue Curves, American Society for Metals, Metals Park, OH, 1986.

S. Cunningham, S. Fawaz, J.A. Harter, A. Litvinov, D. Newman, and H.R. Wu: “AFGROW Material Database,” version 4.0009e.12, downloadable computer software, United States Air Force, 2004.

N.E. Dowling: Mechanical Behavior of Materials: Engineering Methods for Deformation, Fracture, and Fatigue, 2nd ed., Prentice Hall, Upper Saddle River, NJ, 1999.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Stevenson, M.E., McDougall, J.L., Bowman, R.D. et al. Failure analysis of a high-speed pinion shaft. J Fail. Anal. and Preven. 5, 48–54 (2005). https://doi.org/10.1361/15477020522951

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1361/15477020522951