Abstract

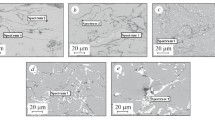

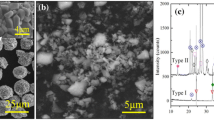

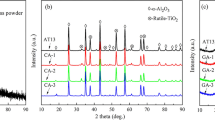

An Al2O3 ceramic coating (A), a 13 wt.% TiO2-Al2O3 (13TA) composite ceramic coating, and a Ni-Al-13wt.%TiO2-Al2O3 (NA-13TA) gradient composite ceramic coating were prepared on Q235 steel by plasma spraying. The corrosion behavior of samples sprayed with these coatings in a boiling 5% HCl solution was investigated. It was shown that an A ceramic coating and a 13TA composite ceramic coating were destroyed after immersion for 17 and 23 h, respectively. The NA-13TA gradient composite ceramic coating was still sound after 14 days of immersion. The corrosion resistance of samples with the NA-13TA gradient composite ceramic coating was sharply improved due to the decreased amount of connected pores in the coating. The corrosion of the sample sprayed with the gradient ceramic coating included the partial corrosion of the surface ceramic coating and the interlayer coatings. The corrosion weight loss depended on the degree of open porosity.

Similar content being viewed by others

References

M.L. Thorpe, How Recent Advances in Arc Spraying Technology Have Broadened the Ranges of Applications, Proceedings of ITSC’ 88, 1988, p 376–383

S. Hisao, High Technology Ceramic, Trans., Tung-Chi University Press, Shanghai, China, 1990, p 17 (in Chinese)

J.X. Zheng, X. Ai, and Z.L. Ding, Oxidation of Al2O3/TiB2/SiCW Ceramic Composite, J. Chinese. Soc. Corros. Protect., Vol 17 (No. 2), 1997, p 152–156 (in Chinese)

J.P. Cai and B. Li, Thermal Spraying Ceramic Coatings, Mater. Mech. Eng., Vol 24 (No. 1), 2000, p 5–7 (in Chinese)

Y. Dianran, H. Jining, W. Jianjun, Q. Wanqi, and M. Jing, The Corrosion Behaviour of a Plasma Spraying Al2O3 Ceramic Coating in Dilute HCl Solution, Surf. Coat. Technol., Vol 89 (No. 2–3), 1997, p 191–195

M.A. Uusitala, P.M.J. Vuristo, and T.A. Mantyla, High Temperature Corrosion of Coatings and Boiler Steels in Reducing Chlorine-Containing Atmosphere, Surf. Coat. Technol., Vol 161 (No. 2–3), 2002, p 275–285

M. Fukumoto, Y. Wada, M. Umemoto, and O. Kane, Effect of Connected Pores on the Corrosion Behaviour of Plasma Spraying Alumina Coatings, Surf. Coat. Technol., Vol 39/40. 1989, p 711–720

Lai, Z.A. Munir, B. Mccoy, and S.H. Risbud, Formation of Functionally Graded Materials Through Centrifugally-Assisted Combustion Synthesis, Proceeding of the Fourth International Smposium on Functionally Graded Materials, 1996, p 275–281

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Yan, D., He, J., Li, X. et al. Corrosion behavior in boiling dilute HCI solution of different ceramic coatings fabricated by plasma spraying. J Therm Spray Tech 13, 503–507 (2004). https://doi.org/10.1361/10599630421514

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1361/10599630421514