Abstract

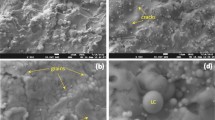

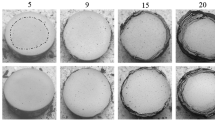

The hot-corrosion behavior of thermal barrier coatings (TBCs) has been studied by comparing double-layer coatings and graded coatings. Two types of oxide ceramics, 2CaO·SiO2-15mass%CaO·ZrO2 (C2S-15CZ) and 8 mass% Y2O3·ZrO2 (8YSZ), with a bond coating of NiCrAlY, were applied to metallic substrates in this study. After hot-corrosion testing with V2O5-Na2SO4 corrosive ash for 3 h at 1273 K, the TBCs were investigated by visual inspection, a scanning electron microscope, x-ray diffraction, and electron probe microanalysis. The findings for the resulting coating of C2S-15CZ reacted with V2O5 only where it was in direct contact with the corrosive ash. The affected area from the reaction was limited to the coating surface where V2O5 was present. The coating showed adequate hot-corrosion resistance against V2O5-Na2SO4 corrosive ash for 3 h at 1273 K. The findings for the 8YSZ coating were that Y2O3, the stabilizing component, particularly reacted with V2O5 and lost its function, which led to partial spalling of the coating. It was observed that the hot-corrosion resistance of the double-layer TBC was largely influenced by the performance of a corrosion-resistant NiCrAlY bond coat, which provided protection against corrosive components penetrating through the ceramic topcoat. Last, the graded coating degraded due to the oxidation of NiCrAlY particles that existed near the topcoat surface and affected the durability of the TBC.

Similar content being viewed by others

References

H. Takeda, T. Suzuki, M. Ito, and Y. Takahashi, Gas Turbine Environments and Super Heat-Resistant Coatings, J. Met. Finish. Soc. Jpn., Vol 38 (No. 12), 1987, p 586–591 (in Japanese)

N. Iwamoto, Development on Coatings for Gas Turbine, Trans. Iron Steel Inst. Jpn., Vol 73, 1987, p 2187–2198 (in Japanese)

P.E. Hodge, S. Stecura, M.A. Gedwill, and I. Zaplatynsky, “Thermal Barrier Coatings: Burner Rig Hot Corrosion Test Results,” NASA TM-79005, National Aeronautics and Space Administration, 1978

T. Suzuki and H. Takeda, Laser Surface Modification for Thermal Barrier Coatings, Bull. Ceram. Soc. Jpn., Vol 25 (No. 10), 1990, p 964–969 (in Japanese)

T. Hashida, H. Takahashi, and K. Miyawaki, Evaluation of Thermal Shock Fracture of Functionally Gradient Materials, J. Jpn. Soc. Powder Powder Metall., Vol 37 (No. 2), 1990, p 307–312 (in Japanese)

V. Pilous and J. Musil, Plasma Spraying of Graded Metal Ceramic Coatings, Mater. Sci. Forum, Vol 62 (No. 64), 1990, p 317–318

K. Kokini, J. DeJonge, S. Rangaraj, and B. Beardsley, Thermal Shock of Functionally Graded Thermal Barrier Coatings with Similar Thermal Resistance, Surf. Coat. Technol., Vol 154 (No. 2–3), 2002, p 223–231

K.A. Khor, Y.W. Gu, and Z.L. Dong, Mechanical Behavior of Plasma Sprayed Functionally Graded YSZ/NiCrAlY Composite Coatings, Surf. Coat. Technol., Vol 139 (No. 2–3), 2001, p 200–206

H. Nakahira, Y. Harada, N. Mifune, and T. Yagoro, High Temperature Stabilities of 2CaO2-SiO2-CaO·ZrO2 Thermal Barrier Coatings Formed by Plasma Spraying Process, J. Gas Turbine Soc. Jpn., Vol 20 (No. 77), 1992, p 52–59 (in Japanese)

H. Nakahira, Y. Harada, N. Mifune, and T. Yagoro, Advanced Thermal Barrier Coatings Involving Efficient Vertical Microcracks, J. Thermal Spray Technol., Vol 2, 1993, p 51–58

N. Mifune, Y. Harada, H. Taira, and S. Mishima, Field Evaluation of 2CaO·SiO2-CaO·ZrO2 Thermal Barrier Coating on Gas Turbine Vanes, Proceedings of 10th Thermal Spray Conference, Thermal Spray: A United Forum for Scientific and Technological Advance, C.C. Berndt, Ed., American Society of Mechanical Engineering, 1997, p 299–303

P. Vincenzini, Zirconia Thermal Barrier Coatings for Engine Applications, Ind. Ceram., Vol 10 (No. 3), 1990, p 113–126

High Temperature Oxidation and High Temperature Corrosion of Metals, The Japan Society of Corrosion Engineering/Maruzen Co., Ltd., Tokyo, Japan, 1982, p 97 (in Japanese)

A.S. Nagelberg, Destabilization of Yttria-Stabilized Zirconia Induced by Molten Sodium Vanadate-Sodium Sulfate Melts, J. Electrochem. Soc., Vol 132 (No. 10), 1985, p 2502–2507

Y. Mutoh, I. Sakamoto, and T. Nishimura, Failure Characteristics of Thermal-Cycled Zirconia Coatings, J. Jpn. Thermal Spraying Soc., Vol 26 (No. 3), 1989, p 1140–1149 (in Japanese)

M. Yoshiba, K. Abe, T. Aranami, and Y. Harada, High-Temperature Oxidation and Hot Corrosion Behavior of Two Kinds of Thermal Barrier Coating Systems for Advanced Gas Turbines, J. Thermal Spray Technol., Vol 5 (No. 3), 1996, p 259–268

Y. Tsunekawa, H. Harada, M. Okumiya, and I. Niimi, Heat Transfer in Thermal Barrier Coatings with Gradient Constituents Fabricated by Low Pressure Plasma Spraying, J. Jpn. Inst. Met., Vol 54 (No. 11), 1990, p 1256–1260 (in Japanese)

T. Aihara, M. Kaji, and T. Igarashi, Numerical Analysis of Compositional Distribution Change in Functionally Gradient Materials, J. Jpn. Inst. Metals, Vol 54 (No. 7), 1990, p 758–763 (in Japanese)

D.S. Duvall and D.L. Ruckle, “Ceramic Thermal Barrier Coatings for Turbine Engine Components,” 82-GT-322, American Society of Mechanical Engineers, 1982

F.C. Toriz, A.B. Thakker, and S.K. Gupta, “Thermal Barrier Coatings for Jet Engines,” 88-GT-279, American Society of Mechanical Engineers, 1988

Y.J. Kim, T. Hashida, H. Takahashi, and K. Fujii, Evaluation of Mechanical Properties of Plasma Sprayed Zirconia/NiCrAlY Coating System by Means of Small Punch Testing Method, J. Jpn. Thermal Spray. Soc., Vol 33 (No. 2), 1996, p 9–16 (in Japanese)

I.M. Allam, D.P. Whittle, and J. Stringer, The Oxidation Behavior of CoCrAl Systems Containing Active Element Additions, Oxid. Met., Vol 12 (No. 1), 1978, p 35–66

Y. Itoh, Y. Ishiwata, and H. Kashiwaya, Microstructure and Thermal Conductivity of Thermal Barrier Coating, J. Ceram. Soc. Jpn., Vol 98 (No. 6), 1990, p 561–566 (in Japanese)

M. Narumi, Z. Yu, H. Tarumi, and T. Narita, Oxidation Behavior of Plasma Sprayed CoNiCrAlY/YSZ Film at 1173 and 1273 K in Air, Zairyou-to-Kankyo, Vol 50, 2001, p 466–471 (in Japanese)

K. Ogawa, T. Masuda, and T. Shoji, Kinetics of Thermally Grown Oxide at Interface Between Thermal Barrier Coatings and MCrAlY Bond Coat, Proceedings of International Thermal Spray Conference, Thermal Spray 2001: New Surfaces for a New Millenium. C.C. Berndt, Ed., American Society of Mechanical Engineers, 2001, p 187–194

L. Lelait, S. Alperaine, and R. Mevrel, Alumina Scale Growth at Zirconia-MCrAlY Interface, J. Mater. Sci., Vol 27, 1992, p 5–12

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Mifune, N., Harada, Y., Doi, T. et al. Hot-corrosion behavior of graded thermal barrier coatings formed by plasma-spraying process. J Therm Spray Tech 13, 561–569 (2004). https://doi.org/10.1361/10599630421497

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1361/10599630421497