Abstract

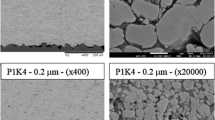

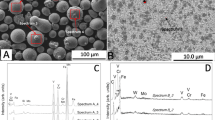

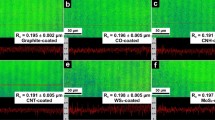

For components that are required to function in sliding or rubbing contact with other parts, degradation often occurs through wear due to friction between the two contacting surfaces. Depending on the nature of the materials being used, the addition of water as a lubricant may introduce corrosion and accelerate the degradation process. To improve the performance and increase the life of these components, coatings may be applied to the regions subject to the greatest wear. These coatings may be engineered to provide internal pockets of solid lubricant in order to improve the tribological performance. In the present study, coatings containing a solid lubricant were produced by thermal spraying feedstock powders consisting of a blend of tungsten carbide-metal and a fluorinated ethylene-propylene (FEP) copolymer-based material. The volume content of this teflon-based material in the feedstock ranged from 3.5 to 36%. These feedstocks were deposited using a high velocity oxy-fuel (HVOF) system to produce coatings having a level of porosity below 2%. Sliding wear tests in which coated rotors were tested in contact with stationary carbon-graphite disks identified an optimum level of teflon-based material in the feedstock formulation required to produce coatings exhibiting minimum wear. This optimum level was in the range of 7 to 17% by volume and depended on the composition of the cermet constituent. Reductions in mass loss for the couples on the order of 50% (an improvement in performance by a factor of approximately 2) were obtained for the best performing compositions, as compared to couples in which the coating contained no solid lubricant.

Similar content being viewed by others

References

A. Borisova, Y. Borisov, A. Tunik, L. Adeeva, E. Lugscheider, and C. Herbst: Proc. United Thermal Spray Conf.—UTSC’99, E. Lugscheider and P.A. Kammer, eds., DVS-Verlag, Düsseldorf, Germany, 1999, pp. 174–81.

J.D. Bolton and A.J. Gant: Powder Metall., 1993, vol. 36 (4), pp. 267–74.

H.D. Steffens, J. Wilden, D. Haumann, M. Gramlich, M. Wewel, M. Höhle, and M.C. Nestler: in Thermal Spraying—Current Status and Future Trends, A. Ohmori, ed., High Temperature Society of Japan, Osaka, 1995, vol. 2, pp. 657–62.

J. Voyer and B.R. Marple: Surf. Coat. Technol., 2000, vol. 127, pp. 155–66.

S. Hartmann, F. Bültmann, and F. Janke: Proc. United Thermal Spray Conf.—UTSC’99, E. Lugscheider and P.A. Kammer, eds., DVS-Verlag, Düsseldorf, Germany, 1999, pp. 169–73 (in German).

B.R. Marple and J. Voyer: in Thermal Spray: Surface Engineering via Applied Research, C.C. Berndt, ed., ASM International, Materials Park, OH, 2000, pp. 909–18.

Handbook of Chemistry and Physics, 74th ed., D.R. Lide, ed., CRC Press, Boca Raton, FL, 1993.

Engineered Materials Handbook, vol. 4, Ceramics and Glasses, ASM International, Materials Park, OH, 1991, p. 30.

Polymer Handbook, 3rd ed., J. Brandrup and E.H. Immergut, eds., John Wiley and Sons, New York, NY, 1989, p. V/45.

F.N. Longo: U.S. Patent 5,660, 934, Aug 26, 1997.

Standard Test Method for Wear Rate and Coefficient of Friction of Materials in Self-Lubricated Rubbing Contact Using a Thrust Washer Testing Machine, ASTM D 3702-94 (1999), ASTM, Philadelphia, PA, 1999.

B.R. Marple, B. Arsenault, and J. Voyer: in Thermal Spray: A United Forum for Scientific and Technological Advances, C.C. Berndt, ed., ASM International, Materials Park, OH, 1997, pp. 73–81.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Marple, B.R., Voyer, J. Improved wear performance by the incorporation of solid lubricants during thermal spraying. J Therm Spray Tech 10, 626–636 (2001). https://doi.org/10.1361/105996301770349150

Received:

Issue Date:

DOI: https://doi.org/10.1361/105996301770349150