Abstract

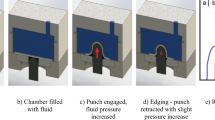

Superplastic forming and diffusion bonding (SPF/DB) production hardware is being fabricated today for aerospace applications. Metal tooling is being used to bring the titanium sheets into contact so diffusion bonding can occur. However, due to material sheet and tooling tolerances, good bond quality is difficult to achieve over large areas. A better method for achieving DB is to use “stop-off” inside sealed sheets of titanium, which constitutes a pack, and then the pack is bonded using external gas pressure. A good method for heating the pack for this process is to use induction heating. Components using “stop-off” that were diffusion bonded first and then superplastically formed have shown much better bond quality than components that were produced using matched metal tooling. This type of tooling has been successful at bonding small areas as long as the exerted pressure is concentrated on the area where bonding is required. Finite element modeling is providing weight effect solutions for titanium SPF/DB aerospace structures.

Similar content being viewed by others

References

D.W. Schulz, SPF/DB Applications for Advanced Turbomachinery, paper 9, Effective Applications of Superplastic Forming and Diffusion Bonding for the Engineering Specialist, SME, 1988

E.J. Tuegel, M.O. Pruitt, L.D. Hefti, SPF/DB Takes Off, Adv. Mater. Process. Inc. Met. Prog., Vol 136 (No. 1), 1989, p 36–41

L.D. Hefti, Applications of SPF and SPF/DB in Fighter Aircraft Structures, paper 10, Effective Applications of Superplastic Forming and Diffusion Bonding for the Engineering Specialist, SME, 1988

J. Pilling and N. Ridley, Superplasticity in Crystalline Solids, 1st ed., Institute of Materials, 1989, p 214

D. Stephens, Designing for Superplastic Alloys, AGARD Lecture Series No. 154, Superplasticity, AGARD, 1987, p 7-1–1-37

M. Hayase, R.C. Ecklund, R.J. Walkington, J.B. Hughes, and N.R. Williams, Method of Fabricating Metallic Sandwich Structure, U.S. Patent 4,217,397, 1980

M.R. Matsen, J.A. Mittleider, R.T. Privett, and D.K. Dabelstein, System and Method for Controlling an Induction Heating Process, U.S. Patent 6,528,771, 2003

D.G. Sanders, A Production System Using Ceramic Die Technology for Superplastic Forming, Superplasticity in Advanced Materials ICSAM 2003, R.I. Todd, Ed., Trans Tech Publications, 2004, p 153–158

L.D. Hefti, Innovations in Fabricating Superplastically Formed Components, First and Second International Symposia on Superplasticity and Superplastic Forming Technology, D.G. Sanders and D.C. Dunand, Ed., ASM International, 2003, p 124–30

N. Rebelo and T.B. Wertheimer, Finite Element Simulation of Superplastic Forming, paper 1, Effective Applications of Superplastic Forming and Diffusion Bonding for the Engineering Specialist, SME, 1988

L.D. Hefti, Using Superplastic Forming as a Means of Achieving Cost Benefits as Well as Enhancing Aircraft Performance, High Performance Metallic Materials for Cost Sensitive Applications, F.H. Froes, E.Y. Chen, R.R. Boyer, E.M. Taleff, L. Lu, D.L. Zhang, C.M. WardClose, and D. Eliezer, Ed., TMS, 2002, p 65–72

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Hefti, L.D. Advances in fabricating superplastically formed and diffusion bonded components for aerospace structures. J. of Materi Eng and Perform 13, 678–682 (2004). https://doi.org/10.1361/10599490421286

Received:

Issue Date:

DOI: https://doi.org/10.1361/10599490421286