Abstract

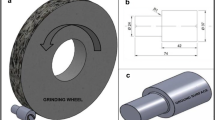

This work outlines the influence of cutting parameters on the superficial hardening of AISI 1045 steel during a grinding process. The parameters are infeed (d), workpiece velocity (v), and cross feed (s). Microstructural changes are also presented. A mathematical expression was obtained that relates the parameters to the maximum hardness obtained for a given cutting condition. No significant microstructure transformations were observed for any of the grinding conditions evaluated; however, changes in the superficial hardness were measured. It was found that when the studied cutting parameters increase, the superficial hardness increases.

Similar content being viewed by others

References

R. Snoeys and J. Peters: “Thermal Induced Damage in Grinding,” Ann. CIRP, 1978, 27(2), pp. 571–81.

S. Malkin: “Grinding of Metals: Theory and Application,” J. Appl. Metalworking, 1984, 3(2), pp. 95–109.

T.C. Jen and A. Lavine: “Variable Heat Flux Model of Heat Transfer in Grinding: Model Development,” J. Heat Transfer (Trans. ASME), 1995, 117(2), pp. 473–78.

A. Lavine and T.C. Jen: “Coupled Heat Transfer to Workpiece, Wheel, and Fluid in Grinding, and the Occurrence of Workpiece Burn,” Int. J. Heat Mass. Transfer, 1991, 30, pp. 251–58.

Y. Ju and T. Farris: “Theoretical Analysis of Heat Partition and Temperatures in Grinding,” J. Tribology, 1998, 120, pp. 789–94.

K. Barker and G. Rowe: “Topography and Mechanical Properties of Grind Metal Surface” in Proc. Inst. Mech. Engs., 1968, 182, pp. 195–204.

Y. Matsumoto and D. Magda: “Effect of Machining Processes on the Fatigue Strength of Hardened AISI 4340 Steel,” J. Eng. Ind. (Trans. ASME), 1991, 113, pp. 154–57.

J. Kholes and P. Field: “Surface Integrity: A Requirement for Surface Generated by Material Removal Methods” in Proc. Inst. Mech. Engs., 1968, 182, pp. 31–42.

R. Poggi and J. Wert: “The Influence of Surface Finish and Strain Hardening on Near Surface Residual Stress on Tool Steel,” Wear, 1991, 149, pp. 209–20.

T. Guest and H. Kolisze: “Applications of Surface Integrity Measurements in Grinding” in Proc. 17th Int. Machine Tool Des. Res., 1980, 1, pp. 189–92.

V. Arshimov and G. Alekseev: Metal Cutting Theory and Cutting Tool Design, Mir Publishers, Moscow, 1970.

D.C. Montgomery and E.A. Peck: Introduction to Linear Regression Analysis, John Wiley and Sons, New York, NY, 1992.

D. Peña: Estadistica, Modelos y Métodos, Fundamentos Alianza Editorial S.A., España, Madrid, Spain, 1994 (in Spanish).

J. Outwater and M. Shaw: “Surface Temperatures in Grinding,” Trans. ASME, 1952, 73, pp. 73–86.

A. Moneim: “The Tribology of the Grinding Process: An Investigation of the Temperature Increase During Grinding,” Wear, 1979, 56, pp. 265–71.

I. Noyan and J. Cohen: “Residual Stresses in Materials,” Am. Sci., 1991, 79, pp. 142–53.

C. Lipsen and N. Steth: Statistical Design and Analysis of Engineering Experiments, McGraw Hill, New York, NY, 1973.

R. Jedamus, R. Taylor, and P. Frame: Statistical Analysis for Business Decisions, McGraw Hill, New York, NY, 1976.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Zurita, O., Acosta, A. & Moreno, D. Superficial hardening in the plane grinding of AISI 1045 steel. J. of Materi Eng and Perform 12, 298–303 (2003). https://doi.org/10.1361/105994903770343141

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1361/105994903770343141