Abstract

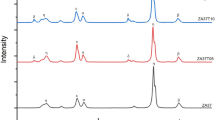

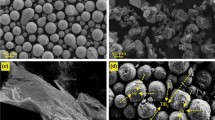

This paper reports an investigation of the mechanical properties and the fracture mechanism of ZA-27 alloy composites containing titanium-dioxide (TiO2) particles 30–50 µm in size and in contents ranging from 0–6 wt.% in steps of 2 wt.%. The composites were fabricated by the compocasting technique. The results of the study revealed improvements in mechanical properties such as Young’s modulus, ultimate tensile strength, yield strength and hardness of the composites, but at the cost of ductility. The fracture behavior of the composites was influenced significantly by the presence of titanium dioxide particles. Crack propagation through the matrix and the reinforcing particles resulted in the final fracture. Scanning electron micrscopy (SEM) analyses were carried out to furnish suitable explanations for the observed phenomena.

Similar content being viewed by others

References

I.A. Ibrahim, F.A. Mohamed, and E.J. Lavernia: “Particulate Reinforced Metal Matrix Composites—A Review,” J. Mater. Sci., 1991, 26, p. 1137.

D. Nath and P.K. Rohatgi: “Fluidity of Mica Particles Dispersed Aluminum Alloys,” J. Mater. Sci., 1990, 15, pp. 2777–84.

S.H.J. Lo, S. Dionne, M. Sahoo, and M.N. Hawthrone: “Mechanical and Tribological Properties of Zinc-Aluminum Metal Matrix Composites,” J. Mater. Sci., 1992, 27, p. 5681.

W. Smith: Structures and Properties of Engineering Alloys, 2nd ed., McGraw Hill, New York, NY, 1993, p. 561.

P.P. Lee, T. Savaskan, and E. Laufer: “Wear Resistance and Microstructure of Zn-Al-Si and Zn-Al-Cu Alloys,” Wear, 1987, 117, p. 79.

H.X. Zhu and S.K. Liu, “Mechanical Properties of Squeeze Cast Zinc Alloy Matrix Composites Containing Alph-Alumina Fibers,” Composites, 1993, 24(6), pp. 437–43.

S. Biswas, E. Dwarakadasa, and S.K. Biswas: in Proc. of All India Seminar on Aluminum, E.S. Dwaragadoss et al., ed., International Conference, Bangalore, 1979, p. 731.

H.J. Lo, S. Dionne, M. Sahoo, and M.N. Hawthorne: “Mechanical and Tribological Properties of Zinc Aluminum Metal Matrix Composites,” J. Mater. Sci., 1992, 27, pp. 5681–91.

T.S. Srivastan: “Microstructure, Tensile Properties and Fracture Behavior of A1203 Particulate Reinforced Aluminum Alloy Metal Matrix Composites,” J. Mater. Sci. 1996, 31, pp. 1375–88.

D.L. McDaneals: “Analysis of Stress-Strain, Fracture, and Ductility Behavior of Aluminum Matrix Composites Containing Discontinuities Silicon Carbide Reinforcement,” Metall. Trans., 1985, 16A, pp. 1105–14.

M.A. Dellis, J.P. Keurstermans, F. Delannay, and J. Wergia: “Zn-Al Matrix Composites, Investigations of the Thermal Expansion, Creep Resistance and Fracture Toughness,” Mater. Sci. Eng., 2001, A135, pp. 253–57.

P.M. Mummery and B. Derby, “The Influence of Microstructure on the Fracture Behavior of Particulate Metal Matrix Composites,” Mater. Sci. Eng., 1991, A135, pp. 221–24.

A.P. Divecha, S.G. Fishman, and S.D. Karmakar, “SiC Reinforced Aluminum-A Formable Composite,” J. Met., 1981, 12, pp. 12–20.

W.H. Hunt, D. Richmond, R.D. Young, F.L. Mathews, “Mechanical Properties of Squeeze Cast Zinc Alloy MMC’s” in Proc. of 6th Int. Conf. on Composite Materials, M.L. Mathew, ed., Elsevier Applied Science, London, United Kingdom, 1987, pp. 2209–18.

K.S. Chan: “Fracture Mechanism and Properties of Metal Matrix Composites” in Key Engineering Materials, G.M. Newaz, H. Neber-Asehbacher, and F.H. Wohlbier, ed., Trans Tech Publication, Aedermansdorf, Switzerland, 1995, Vol. 104, pp. 791–98.

W.W. Gerberich: “Microstructure and Fracture,” ASM Handbook on Mechanical Testing, 1995, 8, pp. 476–92.

V.V. Bhanuprasad, M.A. Staley, P. Ramakrishnan, and Y.R. Mahajan: “Fractography of SiC Particulate Reinforced Aluminum Metal Matrix Composites” in Key Engineering Materials, G.M. Newaz, H. Neber-Aesehbacher, and F.H. Wohlbier, ed., Trans Tech Publication, Aedermansdorf, Switzerland, 1995, 104, pp. 495–506.

Y. Torisaka and S. Kojima: “Superplasticity and Internal Friction of a Superplastic Zn-22%Al Eutectiod Alloy,” Acta Metall. Mater. 1991, 39(5), pp. 947–54.

N.V. Ravi Kumar and E.S. Dwarakadasa: “Effect of Matrix Strength on the Mechanical Properties of Al-Zn-Mg/SiCp Composites,” Composites Part A, 2001, 31, pp. 1139–45.

Y. Chen and M. Tu: “Dimension Shrinkage of Supersaturated ZA27Cu1 and ZA27Cu2 Alloy,” Mater. Sci. Technol., 1998, 14, pp. 473–76.

T. Savaskan and S. Murphy: “Decomposition of Zn-Al Alloy on Quench-Aging,” Mater. Sci. Technol., 1990, 6, pp. 695–703.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ranganath, G., Sharma, S.C., Krishna, M. et al. A study of mechanical properties and fractography of ZA-27/titanium-dioxide metal matrix composites. J. of Materi Eng and Perform 11, 408–413 (2002). https://doi.org/10.1361/105994902770343935

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1361/105994902770343935