Abstract

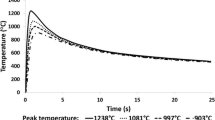

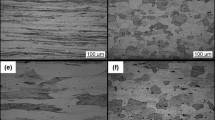

The use of 9Cr-1Mo ferritic steel necessitates its fabrication by the process of welding. The heat-affected zone (HAZ) of 9Cr-1Mo ferritic steel is a combination of many microstructures. In the present study, the corrosion properties of the base metal, weld metal, and the various regions of the HAZ are assessed with respect to their microstructures. The various microstructures in the HAZ were simulated by heat treatment of the normalized and tempered base metal at 1463, 1200, and 1138 K for 5 min followed by oil quenching. The microstructure of the base metal in the normalized and tempered condition revealed martensite laths with M23C6 carbides at lath boundaries, and uniform dispersion of fine, acicular M2C. The weld metal showed predominantly martensitic structure with dispersion of carbides. Simulation of the microstructures of the HAZ by heat treatment resulted in the following microstructures: coarse-grained martensite of 75 µm size at 1463 K, fine-grained martensite at 1200 K, and martensite + proeutectoid α-ferrite at 1138 K. In all cases, carbide precipitation was observed in the martensitic matrix. Microhardness measurements of HAZ-simulated base metal showed increasing hardness with increasing heat treatment temperature. The hardness values obtained corresponded very well with the regions of the actual HAZ in the weld joint. Electrochemical polarization studies were carried out on the base metal, weld metal, weldment (base metal + weld metal + HAZ), and the simulated HAZ structures in 0.5 M sulfuric acid solution. Critical current densities (i crit1 and i crit2), passive current densities (i pass and i sec-pass), and transpassive potential (E tp) were the parameters considered for evaluating the corrosion resistance. The HAZ structures simulated at 1463 and 1200 K, corresponding to coarse- and fine-grained martensitic regions of an actual HAZ, had corrosion properties as good as the normalized and tempered base metal. Of the various simulated HAZ structures, the intercritical region, which was simulated at 1138 K, possessed the worst corrosion resistance. The weld metal possessed the worst corrosion resistance of the various microstructural regions in the weld joint. The weldment adopted the degraded corrosion properties of the weld metal.

Similar content being viewed by others

References

J.A.G. Holmes: Nucl. Eng., 1981, vol. 23, p. 23.

F. Pollard: Proc. ASM Int. Conf. on Production, Fabrication, Properties and Applications of Ferritic Steels for High Temperature Applications, A.K. Khare, ed., ASM, Materials Park, OH, 1981, p. 153.

J. Orr and S.J. Sanderson: Proc. Tropical Conf. on Ferritic Alloys for Use in Nuclear Energy Technologies, Snowbird, UT, J.W. Davis and D.J. Michael, eds., TMS-AIME, Warrendale, PA, 1984, p. 261.

C.A. Hippsley and N.P. Haworth: Mater. Sci. Technol., 1988, vol. 4, p. 791.

H. Kurahashi, T. Kurisu, Y. Sone, K. Wada, and Y. Nakai: Corrosion/84, NACE, Houston, TX, 1984, paper no. 212.

S.K. Banerji, C.J. McMohan, Jr., and H.C. Feng: Metall. Trans. A, 1978, vol. 9A, p. 237.

S.K. Banerji, C.L. Briant, and C.J. McMohan, Jr.: Proc. Conf. on Environment Sensitive Cracking of Materials, The Metals Society, London, 1977, p. 437.

R. Menon and K.K. Khan: “A Report on Transformation, Metallurgical Response and Behavior of Weld Fusion and HAZ in Cr-Mo Steels for Fossil Applications,” Report No. ORNL/Sub/81-07685/02&77, Oak Ridge National Laboratory, Oak Ridge, TN.

B. Paulson: Corr. Sci., 1978, vol. 18, p. 371.

M. Dewitte and C. Coussement: Mater. High Temp., 1991, vol. 9, p. 178.

K. Laha, K.B.S. Rao, and S.L. Mannan: Mater. Sci. Eng., 1990, vol. 129A, p. 183.

J.G. Zhang, F.W. Noble, and B.L. Eyre: Mater. Sci. Eng., 1991, vol. 7, p. 315.

R.S. Fidler and D.J. Gooch: Proc. Int. Conf. Ferritic Steels Fast Reactor Steam Generators, S.F. Pugh and E.A. Little, eds., British Nuclear Energy Society, London, 1978, p. 128.

H.K.D.H. Bhadeshia, S.A. David, and J.M. Vitek: Mater. Sci. Technol., 1991, vol. 7, p. 50.

G.S. Kim, J.E. Indacochea, and T.D. Spry: Mater. Sci. Technol., 1991, vol. 7, p. 42.

C.K. Elliot, G.E. Lucas, R. Maiti, and G.R. Odette: J. Nucl. Mater., 1986, vol. 141–143, p. 439.

R.K. Singh Raman and A.K. Tyagi: Mater. Sci. Eng. A, 1994, vol. 185, p. 97.

N. Parvathavarthini, R.K. Dayal, and J.B. Gnanamoorthy: Corrosion, 1996, vol. 52, p. 540.

O.P. Modi, M.N. Mungole, and K.P. Singh: Corr. Sci., 1990, vol. 30, p. 941.

R.P. Singh, O.P. Modi, M.N. Mungole, and K.P. Singh: Br. Corr. J., 1985, vol. 20, p. 28.

N. Parvathavarthini, R.K. Dayal, and J.B. Gnanamoorthy: Bull. Electrochem., 1990, vol. 691, p. 20.

R.K. Singh Raman and J.B. Gnanamoorthy: Welding J., 1995, vol. 74, p.133-s.

R.K. Singh Raman and J.B. Gnanamoorthy: Corr. Sci., 1993, vol. 34, p. 1275.

K. Laha, K.S. Chandravathi, K.B.S. Rao, and S.L. Mannan: Int. J. Pressure Vessel Piping. 1995, vol. 62, p. 303.

S.J. Sanderson: Proc. Int Conf. on Production. Fabrication, Properties and Applications of Ferritic Steels for High Temperature Applications. Warrendale, PA, Oct. 1981, A.K. Khare, ed., ASM, Metals Park, OH, 1981, p. 85.

P. Patriarca, S.D. Harkness, J.M. Duke, and L.R. Cooper: Nucl. Technol., 1976, vol. 28, p. 516.

S. Saroja, M. Vijayalakshmi, and V.S. Raghunathan: Mater. Trans. Jpn. Inst. Met., 1993, vol. 34, p. 901.

M. Vijayalakshmi, S. Saroja, V. Thomas Paul, R. Mythili, and V.S. Raghunathan: Metall. Trans. A, 1999, vol. 30A, p. 161.

K. Laha: Ph.D. Desertation, Indian Institute of Science, Bangalore, 1998, p. 77.

D.R. Harries: Proc. Conf. on Ferritic Alloys for Use in Nuclear Technology, Snowbird, UT, J.W. Davis and D.J. Michael, eds., TMS-AIME, New York, NY, 1984, p. 141.

B. Buchamyr, H. Cerjak, M. Mitwer, and J.S. Kirkaldy: Proc. Conf. on Recent Trends in Welding Science and Technology, S.D. David and J.M. Vitek, eds., ASM International, Materials Park, OH, 1989, p. 291.

J.N. Soo: CEGB Report No. RD/L/R, CEGB, 1918.

F.B. Pickering and A.D. Vassiliou: Met. Technol., 1980, vol. 7, p. 409.

S. Saroja, M. Vijayalakshmi, and V.S. Raghunathan: J. Mater. Sci., 1992, vol. 27, p. 2389.

J.N. Soo: Proc. Specialist Meeting on Mechanical Properties of Structural Materials Including Environmental Effects, International Atomic Energy Agency (IAEA) and International Working Group on Fast Reactors (IWGFR), Chester, England, 1983, p. 579.

P.J. Alberry and W.K.C. Jones: Met. Technol., 1977, vol. 4, p. 557.

S.N. Banerjee: An Introduction to Science of Corrosion and Its Inhibition, Oxonian Press Pvt. Ltd., New Delhi, p. 185.

H. Shaikh, G. George, F. Schneider, K. Mummert, and H.S. Khatak: Proc. Int. Conf. on Emerging Trends in Corrosion Control-Evaluation, Monitoring and Solutions, A.S. Khanna, K.S. Sharma, and A.K. Sinha, eds., Replica Press Pvt. Ltd., New Delhi, NACE International India Section, 1999, vol. I, p. 32.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

George, G., Shaikh, H., Parvathavarthini, N. et al. On the microstructure-polarization behavior correlation of a 9Cr-1Mo steel weld joint. J. of Materi Eng and Perform 10, 460–467 (2001). https://doi.org/10.1361/105994901770344890

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1361/105994901770344890