Abstract

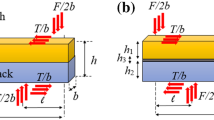

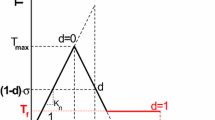

The present paper is concerned with the interfacial fracture problem of bi-material interfaces of superplastic forming/diffusion bonding (SPF/DB) components. It has been known that the interfacial fracture toughness is a strong function of the mode mixture of crack tip, which is the most important characteristic of interfacial problems. Micromechanical models have been proposed to understand this trend of interfacial toughness curves, based on which a modified criterion for fracture under mixed-mode loading is advanced in this paper to predict phenomenological functional forms of toughness curves. On the ground of linear elastic fracture mechanics (LEFM), mode I and mode II interfacial fracture toughnesses of SPF/DB components formed under different processing conditions have been measured in this paper using the double cantilever beam (DCB) and end-notched flexure (ENF) specimens, respectively. It is found that, just as is the general trend of interfacial fracture toughness curves, the experimental results of mode II toughness values are much greater than those of mode I toughness values, and the fluctuation of mode II toughness values under different processing conditions is much greater than that of mode I toughness values. On the basis of the experimental results, the four basic parameters in the modified criterion are obtained and the interfacial toughness curve of Ti-50A/Ti-6Al-4V SPF/DB components is determined using the modified criterion for fracture under mixed-mode loading. Comparison between the results shows that the agreement between experiment and theory is excellent.

Similar content being viewed by others

References

Z. Suo and J.W. Hutchinson: Mater. Sci. Eng. A, 1989, vol. 107, pp. 135–43.

A.G. Evans, M. Ruhle, B.J. Dalgleish, and P.G. Charalambides: Mater. Sci. Eng. A, 1990, vol. 126, pp. 53–64.

A.G. Evans and J.W. Hutchinson: Acta Met., 1989, vol. 37, p. 909.

M. Charalambides, A.J. Kinloch, Y. Wang, and J.G. Williams: Int. J. Fracture, 1992, vol. 54, pp. 269–91.

Wu Shichun: Superplastic Deformation Theory of Metals, National Defense Industry Press, Beijing, 1997 (in Chinese).

J. Dundurs: J. Appl. Mech., 1969, vol. 36, pp. 650–52.

J.G. Williams: Fracture Mechanics of Polymers, Ellls Horwood, Wiley, Chichester, 1984, p. 55.

M.L. Williams: Bull. Seismological Soc. America, 1959, vol. 49, pp. 199–204.

C. Atkinson: Acta Mech., 1977, vol. 26, pp. 103–13.

W. Yang and C.F. Shih: Int. J. Solids Structures, 1994, vol. 31, pp. 985–1002.

J.R. Rice: J. Appl. Mech., 1988, vol. 55, p. 98.

A.G. Evans and J.W. Hutchinson: Acta Metall., 1989, vol. 37, pp. 909–16.

D. Broek: Elementary Engineering Fracture Mechanics, 4th ed., 1986.

A.J. Russell and K.N. Street: Delamination and Debonding of Materials, ASTM STP 876, ASTM, Philadelphia, PA, 1985, p. 349.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Xiang, Y., Wu, S. & Chen, D. Fracture toughness of superplastic formed/diffusion bonded interfaces. J. of Materi Eng and Perform 10, 679–684 (2001). https://doi.org/10.1361/105994901770344548

Received:

Issue Date:

DOI: https://doi.org/10.1361/105994901770344548