Abstract

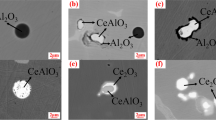

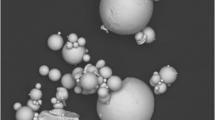

Among the main requirements for the Ni/8% yttria stabilized zirconia (Ni/8YSZ) material, currently used for manufacturing solid oxide fuel cell (SOFC) anodes, fine homogeneous microstructure, considerable structural and mechanical stability, and sufficient gas permeability are of primary concern. In the present investigation, oxide-dispersion strengthened composite Ni powders containing 2, 5, and 10 vol.% 8YSZ were produced by mechanical alloying (MA) in air using a planetary milling machine and ZrO2 milling media. The progress of the MA process was followed by particle size analysis, optical metallography, and x-ray diffraction (XRD) techniques. Results showed that dispersion of the oxide particles and structural refinement reached a significant point after milling for 180 h. The crystallite size and lattice distortion showed considerable dependence on the processing parameters. The mechanically alloyed powders were sintered at 1100° to 1350 °C. The mechanically alloyed powder containing 10 vol.% 8YSZ exhibited maximum densification. The minimum sintered density was observed for the composite powder containing 2 vol.% 8YSZ.

Similar content being viewed by others

References

R.C. Benn and P.K. Mirchandani: in “New Materials by Mechanical Alloying Techniques,” DGM Informationsgesellschaft Verlag, Oberursel, 1989, pp. 19–38.

J.S. Benjamin: Sci. Am., 1976, vol. 234, pp. 40–48.

C.C. Koch: Ann. Rev. Mater. Sci., 1989, vol. 19, pp. 121–143.

R. Orban and S. Domsa: “Powder Metallurgy World Congress,” PM 94, Paris, 1994, vol. 2, p. 1353.

O. Haruyama and N. Asahi: J. Alloys and Compounds, 1993, vol. 194, pp. 361–71.

C.C. Koch, O.B. Cavin, C.G. McKamey, and J.O. Scarbrough: Appl. Phys. Lett., 1983, vol. 43, p. 1017.

J.S.C. Jang and C.C. Koch: J. Mater. Res., 1990, vol. 5 (3), p. 498.

J. Eckert, L. Schultz, and K. Urban: Appl. Phys. Lett., 1989, vol. 55, p. 117.

E. Hellstern, H.J. Fecht, Z. Fu, and W.L. Johnson: J. Appl. Phys., 1989, vol. 65, p. 305.

D. Michel, F. Faudot, E. Gaffet, and L. Mazerolles: J. Am. Cer. Soc., 1993, vol. 76 (11), p. 2884.

R. Wilkenhoener, T. Kloidt, and W. Mallener: in “Electrochemical Proceedings,” U. Stimming et al., ed., The Electrochemical Society, Inc., Pennigton, NJ, 1997, p. 851.

M.F. Ashby, S. Bahk, J. Bevk, and D. Turnbull: Progr. Mater. Sci., 1980, vol. 25, p. 1.

Y. Arami and O. Iwatsu: J. Jpn. Soc. Powder Powder Metall., 1991, vol. 38, p. 47.

Y. Arami and O. Iwatsu: J. Jpn. Soc. Powder Powder Metall., 1996, vol. 43, p. 1289.

A. Guiner: in “X-Ray Diffraction,” W.H. Freeman, San Francisco, CA, 1963, p. 124.

J. Friedel: “Dislocations,” Pergamon Press, Oxford, United Kingdom, 1964, p. 418.

T.D. Shen, K.Y. Wang, M.X. Quan, and J.T. Wang: J. Mater. Sci. Lett., 1992, vol. 11, p. 1570.

Y.H. Zhou, M. Harrmelin, and J. Bigot: Scripta Metall., 1989, vol. 23, p. 1391.

M.H. Tikkanen, B.O. Rosell, and O. Wiberg: Powder Metall., 1962, vol. 10, p. 49.

H. Scher and R. Zallen: J. Chem. Phys., 1970, vol. 53, p. 759.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Mohamed, K.E., Buchkremer, H.P. & Stover, D. Characterization and sinterability of oxide-dispersion strengthened nickel powder produced by mechanical alloying. J. of Materi Eng and Perform 9, 370–378 (2000). https://doi.org/10.1361/105994900770345755

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1361/105994900770345755