Abstract

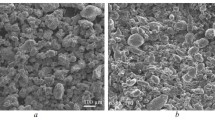

Extremely limited ductility makes several of the processing and manufacturing steps of intermetallic-based materials very critical. The handling of intermetallic cast ingots and the machining of intermetallic components have often proved to be operations with a particularly high failure rate. On the other hand, the processing problems of intermetallic alloys resemble those that are commonly faced with ceramic materials. Therefore, processing routes similar to those used for brittle ceramics have been considered for the manufacturing of intermetallics. In this respect, powder metallurgical methods are certainly very attractive and can potentially help to overcome some of the mentioned drawbacks. In this study, the results of a novel approach to the pressureless forming and sintering of Ni-aluminide powders are presented. This research is an extension of a similar investigation on ceramic (ZrO2 and Al2O3) and metallic (AISI316 inox steel) powders. In all cases, the powders are mixed with a hybrid inorganic-organic binder. The binder-powder mixture can be given the final shape before full polymerization of the binder, which occurs in several minutes at room temperature. Subsequently, debinding and sintering heat treatments are carried out under controlled atmospheres, the composition of which is deliberately changed during the treatments in order to enhance the different processes that are expected to occur. The thermal treatment conditions have been selected and optimized on the basis of thermoanalytical results. The microstructural characterization of the intermediate and final products have been carried out by scanning electron microscopy (SEM) and energy dispersive microanalysis (EDM).

Similar content being viewed by others

References

E.A. Feest and J.H. Tweed: Mat. Sci. Tech., 1992, 8, pp. 308–16.

R.M. German and R.G. Iacocca: “Powder Metallurgy Processing,” in Physical Metallurgy and Processing of Intermetallic Compounds, N.S. Stoloff and V.K. Sikka, ed., Chapman & Hall, New York, NY, 1996, pp. 605–54.

S.C. Deevi, V.K. Sikka, and C.T. Liu: Prog. Mat. Sci., 1997, 42, pp. 177–92.

J. Warren and R.M. German: “The Effect of Powder Characteristics on Binder Incorporation for Injection Molding Feedstock,” in Modern Developments in Powder Metallurgy, Metal Powder Industries Federation, Princeton, NJ, 1988, 18, pp. 391–402.

R. Di Maggio, L. Fambri, and A. Guerriero: Chem. Mater., 1998, 10, pp. 1777–84.

R. Di Maggio, S. Gialanella, and A. Molinari: Proc. of Int. Conf. on Powder Metallurgy & Particulate Materials, W.B. Eisen and S. Kassam, ed., American Powder Metallurgy Indust. International, Princeton, NJ, 2001, 3, pp. 83–90.

R. Di Maggio, L. Lutterotti, P. Giordano Orsini, and S. Gialanella: Proceedings of the 4th European Conference on Advances in Materials and Processes, EUROMAT 95, Associazione Italiana di Metallurgia, Milan, Italy, 1995, 1, pp. 21–26.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Di Maggio, R., Molinari, A. & Gialanella, S. Pressureless forming of NiAl and Ni3Al powders: A preliminary investigation. JPE 23, 68–71 (2002). https://doi.org/10.1361/105497102770332234

Received:

Issue Date:

DOI: https://doi.org/10.1361/105497102770332234