Abstract

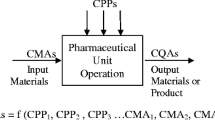

An integrated approach based on QbD and PAT provides a systematic and innovative framework for product development, manufacturing, and quality risk management. In this context, the significance of the outcome of design of experiments (DOEs) to the selection of the product design, robust commercial manufacturing process, design space, and overall control strategy remains vital for the success of a drug product throughout its life cycle. This paper aims at discussing selected recent DOE case studies conducted during QbD-based and integrated QbD/PAT-based development of solid oral formulations and process improvement studies. The main focus of this paper is to highlight the rationales and importance of design selection during development and applications of mathematical models and statistical tools in analyzing DOE and PAT data for developing a design space, control strategy, and improved process monitoring. A total of 25 case studies (includes 9 PAT application studies) have been discussed in this paper which cover 11 manufacturing processes commonly utilized for solid dosage forms. Two case studies relevant to selection of packaging design for solid dosage forms are also briefly discussed to complete the scope. Overall, for a successful modern QbD approach, it is highly important that DOEs are conducted and analyzed in a logical sequence which involves designs that are phase-appropriate and quality-driven and facilitate both statistical and chemometric thinking at each development stage. This approach can result into higher regulatory flexibility along with lower economic burden during life cycle of a product, irrespective of regulatory path used (NDA or ANDA).

Similar content being viewed by others

References

Yu LX. Pharmaceutical quality by design: product and process development, understanding, and control. Pharm Res. 2008;25(4):781–91.

Debevec V, Srčič S, Horvat M. Scientific, statistical, practical, and regulatory considerations in design space development. Drug Dev Ind Pharm. 2018;44(3):349–64.

Q8(R2) ICH harmonized tripartite guideline for pharmaceutical development, current step 4 version dated August 2009 (Accessed Jan 31st, 2019).

FDA Guidance for Industry. Q8 pharmaceutical development. May 2006.

FDA Guidance for Industry. PAT—a framework for innovative pharmaceutical development, manufacturing, and quality assurance. September 2004 (Accessed June 16, 2019).

Report from the EMA-FDA QbD pilot program, April 19, 2017.

Questions and answers on level of detail in the regulatory submissions. EMA/59240/December 10, 2014.

Badawy SI, Narang AS, LaMarche KR, Subramanian GA, Varia SA, Lin J, et al. Integrated application of quality-by-design principles to drug product development: a case study of brivanib alaninate film-coated tablets. J Pharm Sci. 2016;105(1):168–81.

Orloff JJ. The promise and threat of quality risk management. Pharm Technol 2011; 35(2): 38, 40.

Montgomery DC. Design and analysis of experiments. Eight edition. Hoboken: Wiley; 2013. Chapter 1 (p. 3,19), Chapter 11 (p. 501), Chapter 14 (p. 605).

Yu LX, Amidon G, Khan MA, Hoag SW, Polli J, Raju GK, et al. Understanding pharmaceutical quality by design. AAPS J. 2014;16(4):771–83.

Questions and answers on design space verification. EMA/603905/October 24, 2013.

Altan S, Bergum J, Pfahler L, Senderak E, Sethuraman S, Vukovinsky KE. Statistical considerations in design space development (part II of III). Pharm Technol. 2010;34(8):52–60.

Korakianiti E, Rekkas D. Statistical thinking and knowledge management for quality-driven design and manufacturing in pharmaceuticals. Pharm Res. 2011;28(7):1465–79.

Matecka D. Quality issues for clinical trial materials: the chemistry, Manufacturing and Controls (CMC) Review (https://www.fda.gov/downloads/training/clinicalinvestigatortrainingcourse/ucm340005.pdf). Accessed 17 Mar 2019.

Snee RD. Think strategically for design of experiments success. BioProcess Int. 2011 (March): 18–24.

Anderson MJ, Whitcomb PJ. Designing experiments that combine mixture components with process factors, Stat-Ease, Inc. (Accessed 17 Feb 2019).

Rasmuson A, Andersson B, Olsson L, Andersson R. Mathematical modeling in chemical engineering. New York: Cambridge University Press; 2014. Chapter 2. p. 10–8.

Martinello T, Kaneko TM, Velasco MV, Taqueda ME, Consiglieri VO. Optimization of poorly compactable drug tablets manufactured by direct compression using the mixture experimental design. Int J Pharm. 2006;322(1–2):87–95.

Kauffman JF, Geoffroy J-M. Propagation of uncertainty in process model predictions by Monte Carlo simulation. Am Pharm Rev. 2008;11(5):75–9.

Lebrun P, Krier F, Mantanus J, Grohganz H, Yang M, Rozet E, et al. Design space approach in the optimization of the spray-drying process. Eur J Pharm Biopharm. 2012;80(1):226–34.

Lyngberg O, Bijnens L, Geens J, Marchut A, Mehrman S, Schafer E. Applications of modeling in oral solid dosage form development and manufacturing. In: Ierapetritou M, Ramachandran R, editors. Process simulation and data modeling in solid oral drug development and manufacture. Methods in pharmacology and toxicology. New York: Humana Press; 2016. Chapter 1. p. 1–42.

Chatterjee S, Moore CMV, Nasr MM. An overview of the role of mathematical models in implementation of quality by design paradigm for drug development and manufacture. In: Reklaitis GV, Seymour C, García-Munoz S, editors. Comprehensive quality by design for pharmaceutical product development and manufacture. First Edition. Hoboken: Wiley; 2017. Chapter 2. p. 9–24.

Michaels JN, Bonsignore H, Hudson-Curtis BL, Laurenz S, Lin H-R H, Mathai T, et al. Attribute-based design space: materials-science-based quality-by-design for operational flexibility and process portability. J Pharm Innov. 2011;6(4):193–201.

Wu J. Process analytical technology (PAT) in ANDA submissions—advancing generic drug manufacturing. IFPAC Annual Meeting Arlington, VA, January 24, 2014.

Peinado A, Hammond J, Scott A. Development, validation and transfer of a near infrared method to determine in-line the end point of a fluidised drying process for commercial production batches of an approved oral solid dose pharmaceutical product. J Pharm Biomed Anal. 2011;54(1):13–20.

Flåten GR, Ferreira AP, Bellamy L, Frake P. PAT within the QbD framework: real-time end point detection for powder blends in a compliant environment. J Pharm Innov. 2012;7(1):38–45.

Anderson CA, Drennen JK, Ciurczak EW. Pharmaceutical applications of near-infrared spectroscopy. In: Burns DA, Ciurczak EW, editors. Handbook of near-infrared analysis. Third edition. Boca Raton: Taylor & Francis Group, LLC; 2008. Chapter 30. p. 585–611.

Sever NE, Warman M, Mackey S, Dziki W, Min JM. Process analytical technology in solid dosage development and manufacturing. In: Qiu Y, Chen Y, Zhang GGZ, Liu L, Porter WR, editors. Developing solid oral dosage forms: pharmaceutical theory and practice. Burlington: Elsevier; 2009. Chapter 35. p. 827–41.

Kolter K, Flick D. Structure and dry binding activity of different polymers, including Kollidon VA 64. Drug Dev Ind Pharm. 2000;26(11):1159–65.

Augsburger L, Hoag SW. Advances in capsule formulation development and technology. In: Augsburger LL, Hoag SW, editors. Pharmaceutical dosage forms: capsules. Boca Raton: Taylor and Francis Group, LLC; 2018. Chapter 1. p. 1–13.

NIST/SEMATECH e-handbook of statistical methods, http://www.itl.nist.gov/div898/handbook/ Accessed 5 Mar 2019.

Fariss G, Keintz R, Okoye P. Thermal effusivity and power consumption as PAT tools for monitoring granulation end point. Pharm Technol. 2006;30(6):60–72.

Pandey P, Badawy S. A quality by design approach to scale-up of high-shear wet granulation process. Drug Dev Ind Pharm. 2016;42(2):175–89.

Faure A, York P, Rowe RC. Process control and scale-up of pharmaceutical wet granulation processes: a review. Eur J Pharm Biopharm. 2001;52(3):269–77.

van den Ban S, Goodwin DJ. The impact of granule density on tabletting and pharmaceutical product performance. Pharm Res. 2017;34(5):1002–11.

He X, Lunday KA, Li LC, Sacchetti MJ. Formulation development and process scale up of a high shear wet granulation formulation containing a poorly wettable drug. J Pharm Sci. 2008;97(12):5274–89.

Roggo Y, Chalus P, Maurer L, Lema-Martinez C, Edmond A, Jent N. A review of near infrared spectroscopy and chemometrics in pharmaceutical technologies. J Pharm Biomed Anal. 2007;44(3):683–700.

Shikata F, Kimura S, Hattori Y, Otsuka M. Real-time monitoring of granule properties during high shear wet granulation by near-infrared spectroscopy with a chemometrics approach. RSC Adv. 2017;7:38307–17.

Tousey MD. The granulation process 101: basic technologies for tablet making. Pharm Technol. (year book) 2002, 8–13.

Levin M. Wet granulation: end-point determination and scale-up. In: Swarbrick J, editor. Encyclopedia of pharmaceutical technology. Third edition, vol. I. New York: Informa Healthcare USA, Inc.; 2007. p. 4078–98.

Gao JZ, Jain A, Motheram R, Gray DB, Hussain MA. Fluid bed granulation of a poorly water soluble, low density, micronized drug: comparison with high shear granulation. Int J Pharm. 2002;237(1–2):1–14.

Rambali B, Baert L, Massart DL. Using experimental design to optimize the process parameters in fluidized bed granulation on a semi-full scale. Int J Pharm. 2001;220(1–2):149–60.

Balachandran M, Devanathan S, Muraleekrishnan R, Bhagawan SS. Optimizing properties of nanoclay–nitrile rubber (NBR) composites using face centred central composite design. Mater Des. 2012;35:854–62.

Lourenço V, Lochmann D, Reich G, Menezes JC, Herdling T, Schewitz J. A quality by design study applied to an industrial pharmaceutical fluid bed granulation. Eur J Pharm Biopharm. 2012;81(2):438–47.

EMEA Guideline on the use of near infrared spectroscopy by the pharmaceutical industry and the data requirements for new submissions and variations. 27 January 2014 (Accessed June 14, 2019).

FDA Draft Guidance for Industry. Development and submission of near infrared analytical procedures. March 2015 (Accessed June 14, 2019).

Mehta S, De Beer T, Remon JP, Vervaet C. Effect of disintegrants on the properties of multiparticulate tablets comprising starch pellets and excipient granules. Int J Pharm. 2012;422(1–2):310–7.

Désiré A, Paillard B, Bougaret J, Baron M, Couarraze G. Extruder scale-up assessment in the process of extrusion-spheronization: comparison of radial and axial systems by a design of experiments approach. Drug Dev Ind Pharm. 2013;39(2):176–85.

Newton JM. Extrusion and extruders. In: Swarbrick J, editor. Encyclopedia of pharmaceutical technology. Fourth edition. Boca Raton: Taylor & Francis Group, LLC; 2013. p. 1567–84.

Simon O, Guigon P. Interaction between feeding and compaction during lactose compaction in a laboratory roll press. Kona. 2000;18:131–8.

Teng Y, Qiu Z, Wen H. Systematical approach of formulation and process development using roller compaction. Eur J Pharm Biopharm. 2009;73(2):219–29.

am Ende MT, Moses SK, Carella AJ, Gadkari RA, Graul TW, Otano AL, et al. Improving the content uniformity of a low-dose tablet formulation through roller compaction optimization. Pharm Dev Technol. 2007;12(4):391–404.

Sprockel O, Both D. Implementation of QbD: the roles of product attributes and equipment parameters in control loop development. Am Pharm Rev. 2012; August 21 (online article).

Gamble JF, Tobyn M, Dennis AB, Shah T. Roller compaction: application of an in-gap ribbon porosity calculation for the optimization of downstream granule flow and compactability characteristics. Pharm Dev Technol. 2010;15(3):223–9.

Allesø M, Holm R, Holm P. Roller compaction scale-up using roll width as scale factor and laser-based determined ribbon porosity as critical material attribute. Eur J Pharm Sci. 2016;87:69–78.

Boersen N, Belair D, Peck GE, Pinal R. A dimensionless variable for the scale up and transfer of a roller compaction formulation. Drug Dev Ind Pharm. 2016;42(1):60–9.

Shi W, Sprockel OL. A practical approach for the scale-up of roller compaction process. Eur J Pharm Biopharm. 2016;106:15–9.

Fahmy R, Kona R, Dandu R, Xie W, Claycamp G, Hoag SW. Quality by design I: application of failure mode effect analysis (FMEA) and Plackett-Burman design of experiments in the identification of “main factors” in the formulation and process design space for roller-compacted ciprofloxacin hydrochloride immediate-release tablets. AAPS PharmSciTech. 2012;13(4):1243–54.

Allesø M, Torstenson AS, Bryder M, Holm P. Presenting a rational approach to QbD-based pharmaceutical development: a roller compaction case study. Eur Pharm Rev. 2013;18(6):3–10.

Allesø M. QbD in pharmaceutical development: tablet formulation design spaces for direct compression and roller compaction processes. Umetrics User Meeting, Le Méridien Parkhotel, Frankfurt, June 15-16, 2011.

Rantanen J, Jørgensen A, Räsänen E, Luukkonen P, Airaksinen S, Raiman J, et al. Process analysis of fluidized bed granulation. AAPS PharmSciTech. 2001;2(4):13–20.

Lim H, Dave VS, Kidder L, Neil Lewis E, Fahmy R, Hoag SW. Assessment of the critical factors affecting the porosity of roller compacted ribbons and the feasibility of using NIR chemical imaging to evaluate the porosity distribution. Int J Pharm. 2011;410(1–2):1–8.

Hancock BC, Garcia-Munoz S. How do formulation and process parameters impact blend and unit dose uniformity? Further analysis of the product quality research institute blend uniformity working group industry survey. J Pharm Sci. 2013;102(3):982–6.

Adam S, Suzzi D, Radeke C, Khinast JG. An integrated quality by design (QbD) approach towards design space definition of a blending unit operation by discrete element method (DEM) simulation. Eur J Pharm Sci. 2011;42(1–2):106–15.

Chowhan ZT, Chi LH. Drug-excipient interactions resulting from powder mixing. IV: role of lubricants and their effect on in vitro dissolution. J Pharm Sci. 1986;75(6):542–5.

Portillo PM, Ierapetritou M, Tomassone S, Mc Dade C, Clancy D, Avontuur PPC, et al. Quality by design methodology for development and scale-up of batch mixing processes. J Pharm Innov. 2008;3(4):258–70.

Wu H, Khan MA. Quality-by-design (QbD): an integrated approach for evaluation of powder blending process kinetics and determination of powder blending end-point. J Pharm Sci. 2009;98(8):2784–98.

Narang AS. Identification of CPPs based on CQAs & mechanistic process & product understanding: a case study. 2nd FDA/PQRI Conference on Advancing Product Quality Bethesda, MD, October 5–7, 2015.

Huang J, Goolcharran C, Ghosh K. A quality by design approach to investigate tablet dissolution shift upon accelerated stability by multivariate methods. Eur J Pharm Biopharm. 2011;78(1):141–50.

Garcia T, Bergum J, Prescott J, Tejwani R, Parks T, Clark J, et al. Recommendations for the assessment of blend and content uniformity: modifications to withdrawn FDA draft stratified sampling guidance. J Pharm Innov. 2015;10(1):76–83.

FDA Guidance for Industry. Quality attribute considerations for chewable tablets. August 2018 (Accessed March 16, 2019).

FDA Guidance for Industry. Orally disintegrating tablets. December 2008 (Accessed March 16, 2019).

Bahr MN. A design of experiments for tablet compression. Pharm Technol. (Europe) 2011; 23(9): 72–81.

Peeters E, De Beer T, Vervaet C, Remon JP. Reduction of tablet weight variability by optimizing paddle speed in the forced feeder of a high-speed rotary tablet press. Drug Dev Ind Pharm. 2015;41(4):530–9.

Dietrich P, Bauer-Brandl A, Schubert R. Influence of tableting forces and lubricant concentration on the adhesion strength in complex layer tablets. Drug Dev Ind Pharm. 2000;26(7):745–54.

Goodwin DJ, van den Ban S, Denham M, Barylski I. Real time release testing of tablet content and content uniformity. Int J Pharm. 2018;537(1–2):183–92.

Yoshino H, Hara Y, Dohi M, Yamashita K, Hakomori T, Kimura SI, et al. A scale-up approach for film coating process based on surface roughness as the critical quality attribute. AAPS PharmSciTech. 2018;19(3):1243–53.

Agrawal AM, Pandey P. Scale up of pan coating process using quality by design principles. J Pharm Sci. 2015;104(11):3589–611.

Teckoe J, Mascaro T, Farrell TP, Rajabi-Siahboomi AR. Process optimization of a novel immediate release film coating system using QbD principles. AAPS PharmSciTech. 2013;14(2):531–40.

Manca D, Funaro C, Cembali F, Mondelli G, Tarozzi G, Ragazzini PA. How to make a perforated pan PAT-compliant. Pharm Eng. 2008;28(5):1–8.

Naelapää K. Quality by design (QbD) approach in coating: from knowledge base to design space. 3rd PharmSciFair, Pharmaceutical Process Modelling and Simulation, Prague, Czech Republic, June 2011.

Knop K, Kleinebudde P. PAT-tools for process control in pharmaceutical film coating applications. Int J Pharm. 2013;457(2):527–36.

Korasa K, Vrečer F. Overview of PAT process analysers applicable in monitoring of film coating unit operations for manufacturing of solid oral dosage forms. Eur J Pharm Sci. 2018;111:278–92.

Lin H, May RK, Evans MJ, Zhong S, Gladden LF, Shen Y, et al. Impact of processing conditions on inter-tablet coating thickness variations measured by terahertz in-line sensing. J Pharm Sci. 2015;104(8):2513–22.

Frey C. A parameter model for Wurster fluid-bed film coating. Proceedings of 32nd Annual Meeting & Exposition of Controlled Release Society, 2005, Abstract # 489.

Teunou E, Poncelet D. Batch and continuous fluid bed coating—review and state of the art. J Food Eng. 2002;53(4):325–40.

Avalle P, Pollitt MJ, Bradley K, Cooper B, Pearce G, Djemai A, et al. Development of process analytical technology (PAT) methods for controlled release pellet coating. Eur J Pharm Biopharm. 2014;87(2):244–51.

Marucci M, Holmgren A, Carlsson H, Jarke A, Johansson M, Corswant von C. Non-uniformity of pellets coating, effect on the dose release profile and how to improve the coating process by reducing the electrostatic charging of the pellets. Chem Biochem Eng 2012; 26 (4): 379–384.

Sidwell R, Hansell J, Rane M, Rajabi-Siahboomi AR. Characterization of inert cores for multiparticulate dosage forms. In: Rajabi-Siahboomi A, editor. Multiparticulate drug delivery formulation, processing and manufacturing. Springer; 2017. Chapter 2. p. 5–35.

Jones D. Development, optimization, and scale-up of process parameters: wurster coating. In: Qiu Y, Chen Y, Zhang GGZ, Liu L, Porter WR, editors. Developing solid oral dosage forms: pharmaceutical theory and practice. Burlington : Elsevier; 2009. Chapter 34. p. 807–826.

Kramar A, Turk S, Vrecer F. Statistical optimisation of diclofenac sustained release pellets coated with polymethacrylic films. Int J Pharm. 2003;256(1–2):43–52.

Maguire J, Peng D. How to identify critical quality attributes and critical process parameters. FDA/PQRI 2nd Conference, North Bethesda, Maryland, October 6, 2015.

USP chapter <1671> The application of moisture vapor transmission rates for solid oral dosage forms in plastic packaging systems (draft chapter), 2018.

Chen Y. Packaging selection for solid oral dosage forms. In: Qiu Y, Chen Y, Zhang GGZ, Liu L, Porter WR, editors. Developing solid oral dosage forms: pharmaceutical theory and practice pharmaceutical theory and practice. Burlington: Elsevier; 2009. Chapter 24. p. 563–576.

Barry J, Bergum J, Chen Y, Chern R, Hollander R, Klein D, et al. Basis for using moisture vapor transmission rate per unit product in the evaluation of moisture-barrier equivalence of primary packages for solid oral dosage forms. Pharm Forum. 2005;31(1):226–69.

Bergum J, Chen Y, Hunt D, Lockhart H, Malinowski D, Moreton C, O’Reilly D, Wiltulski F (PQRI Container Closure Working Group). Development and application of MVTR/unit data in regulatory submissions. Pharm Forum 2013; 39(6).

Badawy SI, Gawronski AJ, Alvarez FJ. Application of sorption-desorption moisture transfer modeling to the study of chemical stability of a moisture sensitive drug product in different packaging configurations. Int J Pharm. 2001;223(1–2):1–13.

Wass JA. First steps in experimental design II: more on screening experiments. J Valid Technol. 2011[Winter]; pp. 12–20.

Carvalho TC, Escotet ML, Lin J, Sprockel OL. Assessing impact of manufacturing and package configurations to photosensitive compounds. Drug Dev Ind Pharm. 2016;42(6):936–44.

Q1B ICH harmonized tripartite guideline for stability testing: photostability testing of new drug substances and products. Current Step 4 version dated 6 November 1996 (Accessed 15 Feb 2019).

Acknowledgments

The author gratefully acknowledges the contributions of cited authors whose publications helped in developing the analytical insights and personal opinions expressed in this paper. Thanks are due to reviewers for their valuable comments and individual authors and publishers for their kind permissions to reproduce figures and tables used in this manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Singh, B.N. Product Development, Manufacturing, and Packaging of Solid Dosage Forms Under QbD and PAT Paradigm: DOE Case Studies for Industrial Applications. AAPS PharmSciTech 20, 313 (2019). https://doi.org/10.1208/s12249-019-1515-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/s12249-019-1515-8