Abstract

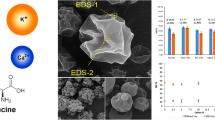

The purpose of this work was to characterize theophylline (THF) cocrystals prepared by spray drying in terms of the physicochemical properties and inhalation performance when aerosolized from a dry powder inhaler. Cocrystals of theophylline with urea (THF-URE), saccharin (THF-SAC) and nicotinamide (THF-NIC) were prepared by spray drying. Milled THF and THF-SAC cocrystals were also used for comparison. The physical purity, particle size, particle morphology and surface energy of the materials were determined. The in vitro aerosol performance of the spray-dried cocrystals, drug-alone and a drug-carrier aerosol, was assessed. The spray-dried particles had different size distributions, morphologies and surface energies. The milled samples had higher surface energy than those prepared by spray drying. Good agreement was observed between multi-stage liquid impinger and next-generation impactor in terms of assessing spray-dried THF particles. The fine particle fractions of both formulations were similar for THF, but drug-alone formulations outperformed drug-carrier formulations for the THF cocrystals. The aerosolization performance of different THF cocrystals was within the following rank order as obtained from both drug-alone and drug-carrier formulations: THF-NIC > THF-URE > THF-SAC. It was proposed that micromeritic properties dominate over particle surface energy in terms of determining the aerosol performance of THF cocrystals. Spray drying could be a potential technique for preparing cocrystals with modified physical properties.

Similar content being viewed by others

References

Begat P, Morton D, Staniforth J, Price R. The cohesive-adhesive balances in dry powder inhaler formulations I: direct quantification by atomic force microscopy. Pharm Res. 2004;21:1591–7.

Paajanen M, Katainen J, Raula J, Kauppinen E, Lahtinen J. Direct evidence on reduced adhesion of salbutamol sulphate particles due to l-leucine coating. Powder Technol. 2009;192:6–11.

Zeng X, Martin G, Tee S, Ghoush A, Marriott C. Effects of particle size and adding sequence of fine lactose on the deposition of salbutamol sulphate from a dry powder formulation. Int J Pharm. 1999;182:133–44.

Gutmann V. The donor–acceptor approach to molecular interactions. New York: Plenum Press; 1978.

Feeley J, York P, Sumby B, Dicks H. Determination of surface properties and flow characteristics of salbutamol sulphate, before and after micronisation. Int J Pharm. 1998;172:89–96.

Begat P, Young P, Edge S, Kaerger J, Price R. The effect of mechanical processing on surface stability of pharmaceutical powders: visualization by atomic force microscopy. J Pharm Sci. 2003;92:611–20.

Fowkes FM. Attractive forces at interfaces. Ind Eng Chem. 1964;56:40–52.

Van Oss C, Good R, Chaudhury M. Additive and nonadditive surface tension components and the interpretation of contact angles. Langmuir. 1988;4:884–91.

Van Oss C. Acid–base interfacial interactions in aqueous media. Colloids Surf, A Physicochem Eng Asp. 1993;78:1–49.

Buckton G. The estimation and application of surface energy data for powdered systems. Drug Dev Ind Pharm. 1992;18:1149–67.

Buckton G, Gill H. The importance of surface energetics of powders for drug delivery and the establishment of inverse gas chromatography. Adv Drug Deliv Rev. 2007;59:1474–9.

Ahfat NM, Buckton G, Burrows R, Ticehurst MD. An exploration of inter-relationships between contact angle, inverse phase gas chromatography and triboelectric charging data. Eur J Pharm Sci. 2000;9:271–6.

Pinto J, Buckton G, Newton J. A relationship between surface free energy and polarity data and some physical properties of spheroids. Int J Pharm. 1995;118:95–101.

Alhalaweh A, Vilinska A, Gavini E, Rassu G, Velaga SP. Surface thermodynamics of mucoadhesive dry powder formulation of zolmitriptan. AAPS PharmSciTech. 2011;12(4):1186–92.

Grimsey IM, Feeley JC, York P. Analysis of the surface energy of pharmaceutical powders by inverse gas chromatography. J Pharm Sci. 2002;91:571–83.

Chiou D, Langrish T. A comparison of crystallisation approaches in spray drying. J Food Eng. 2008;88:177–85.

Basavoju S, Boström D, Velaga S. Indomethacin-saccharin cocrystal: design, synthesis and preliminary pharmaceutical characterization. Pharm Res. 2008;25:530–41.

Jung M, Kim J, Kim M, Alhalaweh A, Cho W, Hwang S, et al. Bioavailability of indomethacin saccharin cocrystals. J Pharm Pharmacol. 2010;62:1560–8.

Schultheiss N, Newman A. Pharmaceutical cocrystals and their physicochemical properties. Cryst Growth Des. 2009;9:2950–67.

Alhalaweh A, George S, Bostrom D, Velaga SP. 1:1 and 2:1 Urea–succinic acid cocrystals: structural diversity, solution chemistry, and thermodynamic stability. Cryst Growth Des. 2010;10:4847–55.

Alhalaweh A, Sokolowski A, Rodriguez-Hornedo N, Velaga SP. Solubility behavior and solution chemistry of indomethacin cocrystals in organic solvents. Cryst Growth Des. 2011;11:3923–9.

Nehm S, Rodriguez-Spong B, Rodriguez-Hornedo N. Phase solubility diagrams of cocrystals are explained by solubility product and solution complexation. Cryst Growth Des. 2006;6:592–600.

Mohammad MA, Alhalaweh A, Velaga SP. Hansen solubility parameter as a tool to predict cocrystal formation. Int J Pharm. 2011;407:63–71.

Alhalaweh A, George S, Basavoju S, Childs SL, Rizvi SAA, Velaga SP. Pharmaceutical cocrystals of nitrofurantoin: screening, characterization and crystal structure analysis. Cryst Eng Comm. 2012;14:5078–88.

Alhalaweh A, Roy L, Rodríguez-Hornedo N, Velaga SP. pH-dependent solubility of indomethacin-saccharin and carbamazepine-saccharin cocrystals in aqueous media. Mol Pharmaceut. 2012. doi:10.1021/mp300189b.

Cassidy A, Gardner C, Jones W. Following the surface response of caffeine cocrystals to controlled humidity storage by atomic force microscopy. Int J Pharm. 2009;379:59–66.

Vehring R. Pharmaceutical particle engineering via spray drying. Pharm Res. 2008;25:999–1022.

Alhalaweh A, Velaga S. Formation of cocrystals from stoichiometric solutions of incongruently saturating systems by spray drying. Cryst Growth Des. 2010;10:3302–5.

Suzuki E, Shimomura K, Sekiguchi K. Thermochemical study of theophylline and its hydrate. Chem Pharm Bull. 1989;37:493–7.

Phadnis NV, Suryanarayanan R. Polymorphism in anhydrous theophylline—implications on the dissolution rate of theophylline tablets. J Pharm Sci. 1997;86:1256–63.

Debnath S, Suryanarayanan R. Influence of processing-induced phase transformations on the dissolution of theophylline tablets. AAPS PharmSciTech. 2004;5:39–49.

Seton L, Khamar D, Bradshaw IJ, Hutcheon GA. Solid state forms of theophylline: presenting a new anhydrous polymorph. Cryst Growth Des. 2010;10(9):3879–86.

Jayasankar A. Understanding the mechanisms, thermodynamics and kinetics of cocrystallization to control phase transformations: The University of Michigan; 2008.

Wiedenfeld H, Knoch F. Arch Pharmacal Res. 1986;319:654–9.

Lu E, Rodríguez-Hornedo N, Suryanarayanan R. A rapid thermal method for cocrystal screening. Cryst Eng Comm. 2008;10:665–8.

Lu J, Rohani S. Preparation and characterization of theophylline-nicotinamide cocrystal. Org Process Res Dev. 2009;13:1269–75.

Kaialy W, Ticehurst MD, Murphy J, Nokhodchi A. Improved aerosolization performance of salbutamol sulfate formulated with lactose crystallized from binary mixtures of ethanol–acetone. J Pharm Sci. 2011;100:2665–84.

Trask AV, Motherwell W, Jones W. Physical stability enhancement of theophylline via cocrystallization. Int J Pharm. 2006;320:114–23.

Hooton JC, German CS, Davies MC, Roberts CJ. A comparison of morphology and surface energy characteristics of sulfathiazole polymorphs based upon single particle studies. Eur J Pharm Sci. 2006;28:315–24.

Sheth A, Grant D. Relationship between the structure and properties of pharmaceutical crystals. Kona. 2005;23:36–48.

Bethune S, Huang N, Jayasankar A, Rodri guez-Hornedo N. Understanding and predicting the effect of cocrystal components and pH on cocrystal solubility. Cryst Growth Des. 2009;9:3976–88.

Tong HHY, Shekunov BY, York P, Chow AHL. Influence of polymorphism on the surface energetics of salmeterol xinafoate crystallized from supercritical fluids. Pharm Res. 2002;19:640–8.

Heng JYY, Thielmann F, Williams DR. The effects of milling on the surface properties of form I paracetamol crystals. Pharm Res. 2006;23:1918–27.

Shekunov BY, Feeley JC, Chow AHL, Tong HHY, York P. Aerosolisation behaviour of micronised and supercritically-processed powders. J Aerosol Sci. 2003;34:553–68.

Chamarthy SP, Pinal R, Carvajal MT. Elucidating raw material variability—importance of surface properties and functionality in pharmaceutical powders. AAPS PharmSciTech. 2009;10:780–8.

Lechuga-Ballesteros D, Charan C, Stults CLM, Stevenson CL, Miller DP, Vehring R, et al. Trileucine improves aerosol performance and stability of spray‐dried powders for inhalation. J Pharm Sci. 2008;97:287–302.

Newell HE, Buckton G, Butler DA, Thielmann F, Williams DR. The use of inverse phase gas chromatography to measure the surface energy of crystalline, amorphous, and recently milled lactose. Pharm Res. 2001;18:662–6.

Tong HHY, Shekunov BY, York P, Chow AHL. Predicting the aerosol performance of dry powder inhalation formulations by interparticulate interaction analysis using inverse gas chromatography. J Pharm Sci. 2006;95:228–33.

Feeley J, York P, Sumby B, Dicks H. Processing effects on the surface properties of α-lactose monohydrate assessed by inverse gas chromatography (IGC). J Mater Sci. 2002;37:217–22.

Acknowledgments

A. Alhalaweh and S. Velaga thank the Kempe Foundation (Kempestiftelserna) for an instrumentation grant. Waseem Kaialy thanks the University of Damascus for providing PhD scholarship.

Author information

Authors and Affiliations

Corresponding author

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

ESM 1

(DOC 234 kb)

Rights and permissions

About this article

Cite this article

Alhalaweh, A., Kaialy, W., Buckton, G. et al. Theophylline Cocrystals Prepared by Spray Drying: Physicochemical Properties and Aerosolization Performance. AAPS PharmSciTech 14, 265–276 (2013). https://doi.org/10.1208/s12249-012-9883-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1208/s12249-012-9883-3