Abstract

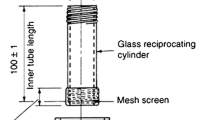

The purpose of this research was to further investigate the hydrodynamics of the United States Pharmacopeia (USP) paddle dissolution apparatus using a previously generated computational fluid dynamics (CFD) model. The influence of paddle rotational speed on the hydrodynamics in the dissolution vessel was simulated. The maximum velocity magnitude for axial and tangential velocities at different locations in the vessel was found to increase linearly with the paddle rotational speed. Path-lines of fluid mixing, which were examined from a central region at the base of the vessel, did not reveal a region of poor mixing between the upper cylin-drical and lower hemispherical volumes, as previously speculated. Considerable differences in the resulting flow patterns were observed for paddle rotational speeds between 25 and 150 rpm. The approximate time required to achieve complete mixing varied between 2 to 5 seconds at 150 rpm and 40 to 60 seconds at 25 rpm, although complete mixing was achievable for each speed examined. An analysis of CFD-generated velocities above the top surface of a cylindrical compact positioned at the base of the vessel, below the center of the rotating paddle, revealed that the fluid in this region was undergoing solid body rotation. An examination of the velocity boundary layers adjacent to the curved surface of the compact revealed large peaks in the shear rates for a region within∼3 mm from the base of the compact, consistent with a ‘grooving’ effect, which had been previously seen on the surface of compacts following dissolution, associated with a higher dissolution rate in this region.

Similar content being viewed by others

References

Cox DC, Wells CE, Furnam WB, Savage TS, King AC. Systematic error associated with apparatus 2 of the USP dissolution test. II: effects of deviations in vessel curvature from that of a sphere. J Pharm Sci. 1982;71:395–399.

Gray VA, Hubert BB. Calibration of dissolution apparatus 1 and 2—What to do when equipment fails. Pharmacopeial Forum. 1994;20:8571–8573.

Achanta AS, Gray VA, Cecil TL, Grady LT. Evaluation of the performance of prednisone and salicylic acid calibrators. Drug Dev Ind Pharm. 1995;21:1171–1182.

McCormick TJ. Industry perspective on dissolution apparatus calibration. Dissolution Technologies. 1995;2:12–15.

Qureshi SA, McGilveray IJ. A critical assessment of the USP dissolution apparatus suitability test criteria. Drug Dev Ind Pharm. 1995;21:905–912.

Qureshi SA, McGilveray IJ. Typical variability in drug dissolution testing: study with USP and FDA calibrator tablets and a marketed drug (glibenclamide) product. Eur J Pharm Sci. 1999;7:249–258.

Carstensen JT. Theory of Pharmaceutical Systems, Volume I. London: Academic Press Inc., 1972:238–241.

Levich VG. Physicochemical Hydrodynamics. Englewood Cliffs, NJ: Prentice-Hall Inc., 1962.

Levich, VG. Theory of concentration polarization. II. Acta Physicochimica U.R.S.S. 1944;19(2–3):117–132.

Grijseels H, Crommelin DJA, de Blaey CJ. Hydrodynamic approach to dissolution rate. Pharm Weekblad Sci Ed. 1981;3:129–144.

Kamba M, Yasuo S, Takeda N, et al. Measurement of agitation force in dissolution test and mechanical destructive force in disintegration test. Int J Pharm. 2003;250:99–109.

Healy AM, McCarthy LG, Gallagher KM, Corrigan OI. Sensitivity of dissolution rate to location in the paddle dissolution apparatus. J Pharm Pharmacol. 2002;54:441–444.

Bocanegra LM, Morris GJ, Jurewicz JT, Mauger JW. Fluid and particle laser Doppler velocity measurements and mass transfer predictions for the USP paddle method dissolution apparatus. Drug Dev Ind Pharm. 1990;16:1441–1464.

Diebold SM. Hydrodynamik und Lösungsgeschwindigkeit-Untersuchungen zum Einfluss der Hydrodynamik auf die Lösungsgeschwindigkeit schwer wasserlöslicher Arzneistoffe 1. ed., Aachen, Germany: Shaker Verlag; 2000.

Diebold SM, Dressman JB. Hydrodynamik kompendialer Lösungsgeschwindigkeits-Testapparaturen. Pharm Ind. 2001;63:94–104.

Kukura J, Arratia PE, Szalai ES, Muzzio FJ. Engineering tools for understanding the hydrodynamics of dissolution tests. Drug Dev Ind Pharm. 2003;29:231–239.

McCarthy LG, Kosiol C, Healy AM, Bradley G, Sexton JC, Corrigan OI. Simulating the hydrodynamic conditions in the United States Pharmacopeia paddle dissolution apparatus. AAPS Pharm Sci Tech. 2003; 4(2): E22.

Levy G, Leonards JR, Procknal JA. Development of in vitro dissolution tests which correlate quantitatively with dissolution rate-limited drug absorption in man. J Pharm Sci. 1965;54:1719–1722.

Scholz A, Kostewicz E, Abrahamsson B, Dressman JB. Can the USP paddle method be used to represent in-vivo hydrodynamics? J Pharm Pharmacol. 2003;55:443–451.

Khoury N, Mauger JW, Howard S. Dissolution rate studies from a stationary disk/rotating fluid system. Pharm Res. 1988;5:495–500.

Schlichting H. Boundary Layer Theory, 4th Edition. New York: McGraw Hill; 1979:225–230.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

McCarthy, L.G., Bradley, G., Sexton, J.C. et al. Computational fluid dynamics modeling of the paddle dissolution apparatus: Agitation rate, mixing patterns, and fluid velocities. AAPS PharmSciTech 5, 31 (2004). https://doi.org/10.1208/pt050231

Received:

Accepted:

DOI: https://doi.org/10.1208/pt050231