Abstract

The aim of the present study is the fabrication of electrochemical sensor and sorbent for toxic Cd(II) ion using ion-imprinting technique on vinyl-functionalized multiwalled carbon nanotube. Multiwalled carbon nanotube-based ion-imprinted polymer (MWCNT-IIP) were synthesized using meth acrylic acid as the functional monomer, N,N′methylene-bis-acrylamide as the cross linking agent, and potassium peroxo disulphate as an initiator. The template and porogen used were cadmium chloride and water. To know the importance of MWCNT, ion-imprinted polymer without MWCNT was also prepared. For the purpose of comparison, non-imprinted polymers were also synthesized. The synthesized products were analyzed by FT-IR, XRD, TEM, EDAX, and TGA. An electrochemical sensor was made up by modifying platinum electrode with MWCNT-IIP. Experimental factors that control the routine of the sensor were investigated and optimized. Under optimal conditions, a calibration curve was obtained with a detection limit of 0.03 μM by using differential pulse voltammetric technique. Selectivity studies show irrelevant significance with Zn (II), Cu (II), and Ni (II) ions. The feasibility of modified platinum electrode shows a prospective application in real water sample collected from a lake, pigments, cosmetics, and fertilizers. The synthesized nanostructured material is also used for the extraction of Cd(II) ion from real water samples. The maximum adsorption of Cd(II) by various imprinted and non-imprinted sorbents was calculated, and it was found that maximum adsorption takes place at pH 6. The kinetic studies show that the adsorption of Cd(II) increases with time and reaches equilibrium at 70 min and the kinetic data follow pseudo-second-order kinetics. The adsorption data fitted to the Langmuir adsorption model which confirms the monolayer formation of an IIP layer on MWCNT surface. The selectivity co-efficient of the imprinted sorbent shows high selectivity and specificity towards Cd(II) ion than other metal ions.

Similar content being viewed by others

Highlights

-

A new method for Cd(II) ion sensing with the advantage of ion-imprinted and electrochemical sensor.

-

The sensor displays lower detection limit compared with the existed methods.

-

MWCNT-IIP sensor displays good selectivity towards Cd(II) ion over other metal ions.

-

Sensor with high sensitivity can be used for sensing and extraction of Cd(II) ion in real samples.

Introduction

Metal pollution in the environment is generally due to the industrial development (Das et al. 2016). Heavy metal ions such as cadmium, lead, chromium, and arsenic are highly toxic to the human health (Das et al. 1997). Cadmium grades ninth among the toxic substance by US disease and poison registry. Cadmium is a dispensable heavy metal which inhibits the enzyme, and it has been considered as the most hazardous pollutant due to its solubility and toxicity in the surroundings. Cd(II) is classified as a type I carcinogen. Exposure to cadmium leads to a variety of undesirable effects such as cancer, growth in the liver and kidney, and softening of bones (Waalkes 2003; Parameswaran and Mathew 2014). There are lots of methods which reported the detection of cadmium ions such as atomic absorption spectrometry (Parham et al. 2009), inductively coupled plasma mass spectrometry (D’Ilio et al. 2005), and inductively coupled plasma atomic emission spectroscopy (Zougagh 2002). Most of these techniques are even though perceptive and precise but are costly and laborious and cause difficulties for in situ sensing. Thus, it is vital to build up an uncomplicated, fast, and cost-effective method for Cd(II) ion detection.

Currently, molecular imprinting technique has been widely used for the development of artificial receptors with high selectivity and affinity towards the target molecule. Due to its advantage such as stable, inexpensive, versatile, and easy to prepare, its application spread to many fields in sensors, catalysis, separation technique, etc. (Kan et al. 2008; Sooraj and Mathew 2014; Mazzotta and Malitesta 2010). MWCNT has large surface area and pore size, so it has been used for electrochemical sensing as the supporting materials for the IIPs. The electrochemical detection is usually performed with a three electrode system containing a working electrode, a reference electrode, and a counter electrode. The working electrode can be modified with different materials for specific recognition of metal ions (Gumpu et al. 2015; Gong et al. 2004; Martínez-Huitle et al. 2010). The presence of metal ions causes the alteration of current, potential which can be used for the sensing of metal ions. Voltammetric method is used for this sensing because of their intrinsic specificity, fast response, low cost, and soaring sensitivity and due to the short analysis time (Wong et al. 2015; Lee et al. 2016a).

In the present work, cadmium ion-imprinted polymers based on multiwalled carbon nanotubes (MWCNT-IIP) for the sensing of cadmium ions have been developed using cadmium ion as a template, methacrylic acid (MAA) as a functional monomer, and N,N′methylene-bis-acrylamide (NNMBA) as a cross linking agent. For smooth interaction and bonding between carbon nanotubes and polymer, MWCNTs are modified with carboxyl functional group which is then converted into acid chloride group and finally to vinyl-functionalized MWCNT. Then, NNMBA and MAA would copolymerize with vinyl groups on the surface of MWCNTs, forming uniform IIP layer. Cyclic voltammetry (CV) technique and differential pulse voltammetry (DPV) technique are used for the sensing of Cd(II) ions using modified platinum electrode (Lee et al. 2016b; Roy et al. 2014). The potential for the sensing of MWCNT-IIP-Pt towards Cd(II) ion was tried against real samples. Subsequent to the flourishing sensing of Cd(II) ion, MWCNT-IIP was also utilized for the extraction of Cd(II) ions from the same sample itself.

Experimental

Materials and methods

MWCNT of 10–15 nm was obtained from Reinsto Nano ventures private limited India; N,N′methylene-bis-acrylamide (NNMBA), potassium peroxo disulphate (K2S2O8), and nafion were purchased from Sigma Aldrich (Germany). Thionylchloride (SOCl2), dimethyl formamide (DMF), and tetrahydrofuran (THF) were obtained from Merck (India). Methacrylic acid (MAA) and metal chlorides were purchased from SRL (India).

The FT-IR spectra were recorded on a Perkin-Elmer 400 FT-IR spectrophotometer. X-ray diffractogram was recorded by PAN analytic XPERT-PRO. TEM-EDAX was investigated by a JEOL-2100 model tunneling electron microscope. Surface area measurements were carried out using Thermofisher Scientific Surfer Analyzer SRFA13/0004. Absorption spectra of Cd(II) ion were recorded by Perkin-Elmer Atomic Absorption Analyser 300. The wavelength selected for the determination of Cd(II) ion is 228.80. Thermo gravimetric analysis was obtained from NETZCHSTA449C instrument. Electrochemical studies were carried out with an electrochemical work station (Biologic SP-200), and cyclic voltammetry and differential pulse voltammetry technique were conceded with platinum wire auxiliary electrode, saturated calomel reference electrode, and a platinum electrode modified with imprinted MWCNT-IIP which was used as the working electrode.

Purification and functionalization of MWCNT

The purchased MWCNT was purified as reported in literature (Shen et al. 2008). The pristine MWCNT was heated in an air oven at 650 °C for 2 h and then allowed to cool followed by the treatment with hydrochloric acid for 2 h. The above mixture was then centrifuged to get the solid. It was then washed with distilled water until the pH becomes neutral. The solid thus obtained was filtered and dried under vacuum.

Purified MWCNT (0.5 g) was treated with 60 ml of con.HNO3 and sonicated for 10 min. This sonicated mixture was refluxed at 60 °C for 24 h. The mixture was filtered and washed with distilled water until the pH of the final wash came down to neutral. The filtered solid was dried under vacuum to obtain carboxyl group incorporated MWCNT (MWCNT-COOH). Carboxylic acid capacity of MWCNT-COOH is calculated by acid–alkali titration and found to be 1.8 mmol/g.

MWCNTs-COOH, 0.4 g, was suspended in a mixture of 10 ml thionyl chloride and 30 ml chloroform in a round bottom flask, refluxed for 24 h at 60 °C. The solid was washed by anhydrous tetrahydrofuran to remove the excess thionyl chloride present on it. It is then dried under vacuum to obtain MWCNT-COCl.

For introducing vinyl group on MWCNT, MWCNTs-COCl was dispersed in 30 ml THF. Twenty microliters of allyl amine dissolved in 10 ml of DMF was added drop wise to the mixture. The mixture was stirred at 60 °C for 24 h and washed with anhydrous THF to remove unreacted reagent. The solid collected was washed with THF and dried under vacuum to get vinyl-functionalized MWCNT (MWCNT-CH=CH2).

Synthesis of IIP on the surface of vinyl-functionalized MWCNTs

Vinyl group incorporated MWCNT (MWCNT-CH=CH2, 0.6 g) was added to the porogen in a 250-ml round bottom flask. Cadmium chloride (0.6 g) and methacrylic acid (0.025 mmol) were added to it and stirred well. Finally, NNMBA (8 g) and potassium peroxo disulphate (100 mg) were also added to it. Then, the mixture was stirred at 70 °C. The obtained polymer was washed with distilled water until no cadmium chloride was detected by AAS in the eluent. MWCNT-NIP was also prepared by the same procedure without using the template molecule. For the purpose of comparison, imprinted polymer was synthesized without using vinyl-functionalized MWCNT and also non-imprinted polymer was prepared without using template molecule.

Modification of platinum electrode and electrochemical sensing

Platinum electrode was polished with 10 μm alumina slurry and sonicated in de-ionize water for 15 min. At this point, the platinum electrode surface would look like a shiny black mirror. At first, Cd(II) ion-imprinted MWCNT-IIP was mixed with 0.5% nafion and sonicated for 10 min to get MWCNT-IIP nafion complex and coated on platinum electrode and then allowed to dry at room temperature; the same procedure was performed with MWCNT-NIP (Rezaei and Rahmanian 2011; Roy et al. 2014; Shen et al. 2008; Legeai and Vittori 2006; Diouf et al. 2017; Trani et al. 2017). MWCNT-IIP modified on the platinum electrode was designated as Pt-MWCNT-IIP (Scheme 1). Nafion were used to solubilize and immobilize imprinted MWCNT-IIP, and they will provide strong ability against electrode fouling. Phosphate buffer (pH 7) was used to blend the reagents, and it contributes conductivity to the paste. Cyclic voltammogram was recorded from − 300 to 1000 mV for Cd(II) ion in 0.1 M phosphate buffer solution. Differential pulse voltammetry was carried out in 0.1 M phosphate buffer solution with successive adding up of different concentration of Cd(II) ion at a pulse amplitude 50 mV, sample width 50 ms, and pulse width 500 ms. Effects of scan rate and pH were also carried out (Veerakumar et al. 2016; Sooraj and Mathew 2014, Trani et al. 2017Han et al. 2013; Fotouhi et al. 2012; Rezaei and Rahmanian 2011). Selectivity studies were evaluated using different metal ions such as Zn (II), Ni (II), and Cu (II) ion. All these studies were carried out at room temperature.

Application of sensor using real samples

The modified platinum electrode was analyzed for Cd(II) ion in real samples collected from a lake (Ashtamudi Lake), pigments, cosmetics, and fertilizers. Real samples were filtered through the 0.22-μm polar size filter paper and used for the analysis. The abovementioned procedure was followed with the sample using MWCNT-IIP and MWCNT-NIP. Electrochemical studies were carried out at a potential range of − 300 to 1000 mV with a scan rate of 100 mV/s.

Extraction procedure

Optimization of adsorption study

Adsorption studies were carried out to investigate the target molecule recognition on the sorbents such as imprinted MWCNT-IIP, IIP, MWCNT-NIP, and NIP. For extraction experiments, batch adsorption method was used. A 10 mg of the sorbent is mixed with 10 ml of Cd(II) solution bearing initial concentration ranging from 1 to 5 ppm. The eluent obtained from the centrifugation was determined with AAS at wavelength 228.80. The concentration range is obtained from the calibration curve of Cd(II) solution bearing different concentration. The amount of Cd(II) ion bound by the sorbent was calculated by Eq. (1).

where Q (μmol/g) is the adsorption capacity, V (ml) is the volume of the solution, M (g) is the mass of the polymer, and Co and Ce (mmol L−1) are the concentration of template before and after extraction process.

The kinetic studies were carried out at different time interval varying from 0 to 100 min by keeping Cd(II) ion concentration constant. The adsorption of Cd(II) ion on MWCNT-IIP, IIP, MWCNT-NIP, and NIP were carried out at different pH values. The selectivity studies were carried out with other metals having ionic nature analogous to Cd(II) ion. Separation and selectivity factor was calculated by the below Eqs. (2)–(4).

DCd and DM represent adsorption ratios of Cd(II) ion and other metal ions. αi and αn are the selectivity factor of imprinted MWCNT-IIP and MWCNT-NIP. αr is the relative selective co-efficient. Factors which affect the adsorption such as template–monomer ratio (Waalkes 2003; Wei et al. 2012; Rezaei and Rahmanian 2011; Mhammedi et al. 2009), effect of mass, and effect of solvent were also determined. Reusability studies were carried out by adsorption desorption experiment (Wong et al. 2015). Swelling studies were carried out, and EWC% (equilibrium water content) was calculated by the below Eq. (5).

Application of the extraction method

The water samples collected from a lake, pigments, cosmetics, and fertilizers were filtered using Whatman no. 1 filter paper. The Cd(II) ion extraction using various ion-imprinted and non-imprinted polymers were carried out using the above explained extraction procedure.

Results and discussion

Characterization

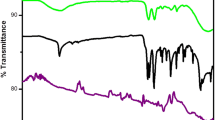

FT-IR spectra were used to confirm the molecular arrangement of all intermediate and product of MWCNT-IIP (Fig. 1). The appearance of band at 1532 cm−1 (C==C) and 1659 cm−1 (N-H) stretching confirms the vinyl group formation on MWCNT-COCl. IIP and MWCNT-IIP give remarkably dissimilar spectra. The peak in the section below 1000 cm−1 is assigned for M-L complexes. The main peaks of bulk IIP and MWCNT-CH=CH2 were present in the spectrum of MWCNT-IIP which confirms the formation of an IIP layer on MWCNT-IIP.

The X-ray diffraction technique is usually used to find out the crystalline nature of polymers. X-ray beams were completely scattered in the case of non-crystalline polymer, thus getting the broad peaks. An X-ray diffract gram of MWCNT, MWCNT-IIP, and bulk IIP is shown in the Fig. 2. MWCNT shows two distinctive peaks at 2θ = 26° and 2θ = 47.8° which verify the crystalline nature of MWCNT. On comparing X-ray diffract gram of MWCNT and MWCNT-IIP, the intensity of the MWCNT-IIP peak decreased due to the wrapping by the polymer layer. IIP shows no peaks due to the amorphous nature.

Thermogravimmetric analysis was done to study the thermal behavior of MWCNTs, MWCNT-IIP, and bulk IIP (Fig. 3). Thermogram of pristine MWCNTs shows a linear model up to 800 °C representing its high thermal stability. On comparing the thermogram of MWCNT-IIP and bulk IIP, the degradation temperature and mass loss were lesser and upper respectively for bulk IIP than MWCNT-IIP. The thermal stability is greater for MWCNT-IIP than for bulk IIP due to the encapsulation of MWCNT to the IIP layer.

The surface morphological analysis of pristine MWCNT, MWCNT-IIP, and bulk IIP was carried out by HR-TEM. Pristine (Fig. 4) MWCNT shows a thread-like nanotube structure with a diameter ranging from 6 to 8 nm. On further functionalization and polymerization, it is found that the thickness of the nanotube was started to increase from 22 to 26 nm. This result clearly specifies the covering of imprinted layer on the surface of MWCNT, thereby providing binding cavities to the surface. Coagulated structure is shown by the bulk IIP, which may be due to the agglomeration on the polymer surface.

The EDAX is helpful to provide the elemental composition of Cd(II) loaded and eluted MWCNT-IIP (Fig. 5a, b). On comparing EDAX images, the signal due to Cd(II) can be observed on MWCNT-IIP and the signal is absent in the case of Cd(II)-eluted MWCNT-IIP. This result confirms the number of cavities on imprinted MWCNT-IIP ease diffusion of the target metal ions. This proved that imprinted MWCNT-IIP has high warmth towards Cd(II) ions.

The surface area analysis of various tailored polymers was investigated using BET method. The specific surface area of the MWCNT-IIP and IIP calculated was 296.8871 and 176.2139 m2/g. Compared with IIP, MWCNT-IIP has a high specific surface area, due to the presence of MWCNT which could effectively enhance the adsorption of Cd(II) on the surface of the adsorbent.

The competence of the synthesized polymer was realized by swelling studies. The extent of swelling is influenced by the nature of polymer strength and extent of crosslinking. The swelling behavior of Cd(II) ion on MWCNT-IIP, IIP, MWCNT-NIP, and NIP was studied and tabulated in Table 1. The maximum swelling behavior is obtained for Cd(II) ion-imprinted MWCNT-IIP due to the cavity left by the Cd(II) ion on MWCNT-attached polymer network.

The dispersion of MWCNT, functionalized MWCNT, and MWCNT-IIP is shown in Fig. 6, where it is clear that the crude MWCNT was aggregated easily and precipitated at the bottom of the container. On functionalizing, it is clear by the naked eye that it shows an increase in dispersibility. Crude MWCNT after functionalization and polymerization is easily dispersed, and the dispersed solution has no change even after 6 months.

Electrochemical studies

To confirm the formation of an electrochemical sensor, cyclic voltammetry of a bare electrode and electrode modified with different adsorbent such as MWCNT-IIP and MWCNT-NIP is compared and shown in Fig. 7. From the figure, it is clear that there is a great difference in the cyclic voltammograms. When the electrode was modified with Cd(II) ion-imprinted MWCNT-IIP, and introducing Cd(II) ion into the modified electrode due to the conductivity of the metal ion, more current is needed to sense the Cd(II) ion; thus, the peak current increases apparently and we get a redox peak. On comparing cyclic voltammogram of Pt-MWCNT-NIP-modified electrode with Pt-MWCNT-IIP electrode, Pt-MWCNT-IIP electrode shows a better current response due to the cavity of the template molecule additional to the good electrical conductivity and high surface area of MWCNT. Thus, MWCNT-IIP-modified platinum electrode was chosen for further studies.

Effect of concentration

The influence of Cd(II) ion concentration in MWCNT-IIP-modified platinum electrode was studied. The voltammetric experiments were limited to a maximum Cd(II) ion concentration of 5 ppm, and the electrochemical measurement obtained was shown in Fig. 8. The redox peak current increases linearly with the Cd(II) ion concentration up to 5 ppm. This is due to the increased availability of the electro active species present in the solution. At higher concentration, no evident peak current was observed because Cd(II) ion gets adsorbed on the electrode surface.

Effect of pH

The routine of MWCNT-IIP sensor depends upon the pH of the solution. The effect of pH on the modified electrode has been investigated by varying over the pH range 2–7. The redox peak current of Cd(II) ion was increased with increasing pH (Fig. 9). At pH 6, maximum redox current was obtained for Cd(II) ion sensing. Above pH 6, the current goes on decreasing due to the decrease of degree of the protonation of Cd(II) ion.

Effect of scan rate

The cyclic voltammogram of Cd(II) ion-imprinted MWCNT-IIP sensor measured with different scan rate ranging from 10 to 100 mVs−1 in the potential range from − 1 to 1 V is shown in Fig. 10. As the scan rate increases, the peak current moves to more current values. As viewed from the figure, the redox peak current was proportional to the scan rate in the range 10–100 mVs−1 with a correlation co-efficient of 0.9918 which confirms that the reaction occurring on the modified platinum electrode was irreversible. Since the plot of scan rate versus current is linear, it proved that the redox process is diffusion controlled.

Selectivity studies

Selectivity studies were carried out with platinum electrode modified with Cd(II) ion-imprinted MWCNT-IIP. Due to their closer ionic nature, Cu, Ni, and Zn were chosen for selectivity studies. Selectivity studies were carried out by successive addition of metals into 0.1 M phosphate buffer solution with regular time intervals (Fig. 11). The result shows redox peak current response for Cd(II) ion compared to other metal ions. Since the platinum electrode was modified with Cd(II) ion-imprinted MWCNT-IIP, it can be selectively uptake Cd(II) ion while other existed cations are not absorbed noticeably due to non-specific cavity. From the above result, it is clear that the modified electrode reduced the influence of other metal ions and showed greater selectivity for Cd(II) ions.

Differential pulse voltammetry

Differential pulse voltammetric measurements were calculated to realize the lower detection limit of the modified electrode. The DPV curve obtained for Cd(II) ion concentration in phosphate buffer solution is depicted in Fig. 12. The studies have shown that DPV enables evaluation of Cd(II) ion down to 1 ppm. Preconcentration time is also an important factor while carrying out DPV experiments. The relationship between current and time would change from linearity when the time taken for the experiment was longer and the preconcentration time was chosen as 5 min. This may be due to the surface saturation; the cavities in the platinum electrode are not free to accommodate Cd(II) ions. The calibration curve was found to be linear with correlation co-efficient 0.9979 and slope of 0.1153. From the calibration curve, the detection limit was found to be 0.03 μM. When the metal concentration was greater than the detection limit, the potential of current responses decreases, due to the saturation of modified platinum electrode.

Application of modified electrode

The applicability and practicability of the projected electrode for the analysis of real sample with different matrices were assessed by its application towards real samples including lake water, pigments, cosmetics, and fertilizers. The result obtained is shown in Table 2. The obtained results confirm the applicability of the method for the determination of Cd(II) ion in a wide variety of real samples.

Comparison with other reported electrodes

The limit of detection of the modified electrode was compared with other reported electrodes. It is comparatively better with some of the previously reported electrodes (Table 3).

Extraction studies

Template–monomer interaction study

The structure and strength of the polymer affinity are related to the complex formed between the template and monomer. In the case of molecular imprinting technique, the selection of functional monomer is very significant whether it interacts with the template molecule very strongly or not. Monomer (MAA) with different concentration is titrated against a particular concentration of template (Cd(II)). From Fig. 13, it is clear that with the increase of the concentration of MAA, the absorbance also increases, which confirms the strong bond formation between template and monomer.

Effect of solvent

A study of the effect of solvent on extraction of Cd(II) ion in which definite quantity of MWCNT-IIP, IIP, MWCNT-NIP, and NIP were treated with Cd(II) ion in H2O, acetonitrile, and methanol was carried out. From Fig. 14, it is clear that the binding is maximum in the case where the binding medium and porogen used for the polymerization are same.

Effect of concentration

The maximum amount of Cd(II) ion bound on different adsorbent with different concentration is shown in Fig. 15a. The figure shows Cd(II) ion adsorption increases from 1 to 5 ppm and the binding capacity is greater for MWCNT-IIP as compared to the other adsorbents due to the incorporation of nanomaterials into the polymer matrix and thus the number of binding sites and surface area increases. The lower adsorption of MWCNT-NIP and NIP is due to the absence of binding sites. Adsorption isotherm data of MWCNT-IIP is fitted with Langmuir adsorption isotherm with R2 value obtained which is 0.99633 (Fig. 15b). The results revealed confirm the homogeneous distribution and monolayer coverage on MWCNT-IIP.

Effect of pH

pH plays an important role on metal ion adsorption. Cd(II) ion adsorption on different adsorbent such as MWCNT-IIP, IIP, and MWCNT-NIP exhibits a high affinity at pH 6 (Fig. 16). At low pH value, lower adsorption of Cd(II) is observed because of the protonation of the binding site of Cd(II) ion. Cd(II) ion adsorption increases as the pH value increases until the pH becomes 6 and then the adsorption was not carried out due to the precipitation formation between high concentration of hydroxide ion and Cd(II) ion. On comparing Cd(II) ion adsorption on MWCNT-IIP and MWCNT-NIP, the percentage of adsorption was enhanced in MWCNT-IIP due to the presence of cavities left by the template molecule.

Effect of time

Kinetic studies were carried out to examine the adsorption rate law and sorption mechanism of Cd(II) ion on different adsorbent such as MWCNT-IIP, IIP, MWCNT-NIP, and NIP. The pseudo-first- and pseudo-second-order Lagregan rate equation was used to study the kinetics of Cd(II) ion adsorption on MWCNT-IIP. The adsorption of Cd(II) ion on MWCNT-IIP, IIP, MWCNT-NIP, and NIP elevates with time and reaches the upper limit. Figure 17a shows two distinctive part in the graph; in the first part of the graph, rapid uptake of Cd(II) ion takes place due to the large binding site availability. And in the second part, adsorption of Cd(II) ion is slow due to saturation of binding sites and attaining equilibrium. Kinetic studies show that adsorption of Cd(II) ion MWCNT-IIP follows the linear form of pseudo-second-order kinetics with R2 value 0.995 and rate constant 0.136 (Fig. 17b).

Effect of mass of the polymer

To study the effect of mass of the polymer for the binding, different amount of adsorbent such as MWCNT-IIP, IIP, MWCNT-NIP, and NIP were equilibrated with a specific volume of Cd(II) ion solution. From Fig. 18, it is clear that as the amount of adsorbent increases, the Cd(II) ion binding also increases. On comparing binding of Cd(II) ion, MWCNT-IIP has the greater binding capacity due to the large surface area and binding site availability in MWCNT-IIP.

Selectivity studies

Selectivity of Cd(II) ion-imprinted and non-imprinted polymers were carried out by rebinding Cd(II) ion in the presence of other metal ions such as copper, nickel, and zinc since it is having similar ionic radius and charge (Fig. 19). On comparing adsorption percentage of metal ions, adsorption is greater for imprinted polymers rather than non-imprinted polymers due to the lack of binding site availability for non-imprinted polymers. The selectivity experiments show that binding capacity of other metal ions is lower than that of Cd(II) ion due to the complimentary cavities fitted for the Cd(II) ions that have been created during imprinting procedure. The selectivity factor was calculated (Table 4). From the observation, it is revealed that Cd(II) ion-imprinted polymers show high selectivity towards Cd-Cu mixture. Cd-Zn mixture shows lower selectivity, and Cd-Ni mixture shows considerable selectivity towards MWCNT-grafted imprinted polymers.

Reusability study

Waste water treatment is more useful when the substance used for the conduct is reusable. Reusability studies were carried out by adsorption–desorption experiment using water as solvent. From Fig. 20, it is clear that the synthesized adsorbent can be used for five cycles of adsorption–desorption experiment and after that adsorption decreased but not clearly. Thus, it was shown that synthesized imprinted MWCNT-IIP is efficiently favorable.

Extraction of Cd(II) ion from real samples

The synthesized imprinted MWCNT-IIP and MWCNT-NIP were applied to the analysis of Cd(II) ion in water samples. The samples were introduced into the imprinted MWCNT-IIP and MWCNT-NIP by method as described above. The results obtained are clearly depicted in Table 5. The results show the appropriateness of Cd(II) ion-imprinted MWCNT-IIP for the extraction of Cd(II) ion.

Conclusions

This study reveals a simple and well-designed approach for the sensing of Cd(II) ions from the real samples through adsorption on mutiwalled carbon nanotube-based ion-imprinting polymer. The modified platinum electrode exhibited a low detection limit of 0.03 μM and a good selectivity, practical applicability for the sensing of Cd(II) ions. At pH 5, maximum sensing was obtained. The plot of current versus concentration of Cd(II) ion gives a straight line passing through the origin, portraying that it is acquiescent for electro analysis of Cd(II) ion. Extraction studies were carried out by batch wise method. The effect of concentration, pH, contact time, and reusability was studied in details. At pH 6, maximum adsorption was obtained. The Langmuir model of cadmium sorption was fitted with Langmuir isotherm which assumed that the sorption was monolayer adsorption with no interaction between adsorbed ions. The adsorption isotherm verified that a homogeneous distribution of binding site with monolayer coverage within MWCNT-IIP takes place, and the sorption process is chemisorption. A pseudo-second-order rate equation can be used to determine the adsorption of Cd(II) onto MWCNT-IIP. Investigations showed that the selectivity of MWCNT-IIP was significantly higher than that of bulk IIP and it can be used as perceptive substances for the sensing of Cd(II) from real samples. This low cost, superficial synthetic route and strength of the surface-imprinted nanostructure IIP provide a useful intermediate for Cd(II) ion extraction from other metal ions which was also confirmed by its high selectivity coefficient.

References

Afkhami A, Soltani-Shahrivar M, Ghaedi H, Madrakian T. Construction of modified carbon paste electrode for highly sensitive simultaneous electrochemical determination of trace amounts of copper (II) and cadmium (II). Electroanalysis. 2015;28:296–303.

D’Ilio S, Petrucci F, D’Amato M, Di Gregorio M, Senofonte O, Violante N. Method validation for determination of arsenic, cadmium, chromium, and lead in milk by means of dynamic reaction cell inductively coupled plasma mass spectrometry. Anal Chim Acta. 2005;624:59–67.

Das N, Bhattacharya S, Maiti MK. Enhanced cadmium accumulation and tolerance in transgenic tobacco overexpressing rice metal tolerance protein gene OsMTP1 is promising for phytoremediation. Plant Physiol Biochem. 2016;105:297–309.

Das P, Samantaray S, Rout GR. Studies on cadmium toxicity in plants: a review. Environ Pollut. 1997;98:29–36.

Diouf A, Motia S, El Alami El Hassani N, El Bari N, Bouchikhi B. Development and characterization of an electrochemical biosensor for creatinine detection in human urine based on functional molecularly imprinted polymer. J Electroanal Chem. 2017;788:44–53.

L. Fotouhi, A. B. Hashkavayi, and M. M. Heravi, “Electrochemical behaviour and voltammetric determination of sulphadiazine using a multi-walled carbon nanotube composite film-glassy carbon electrode,” J Exp Nanosci, 8, 947–956 (2012). X. Fu, Q. Yang, Q. Zhou, Q. Lin, and C. Wang, “Template-monomer interaction in molecular imprinting: is the strongest the best?,” Open J Org Polym Mater, 2, 58–68 (2015).

Gong K, Dong Y, Xiong S, Chen Y, Mao L. Novel electrochemical method for sensitive determination of homocysteine with carbon nanotube-based electrodes. Biosens Bioelectron. 2004;20:253–9.

Gumpu MB, Sethuraman S, Krishnan UM, Rayappan JBB. A review on detection of heavy metal ions in water – an electrochemical approach. Sensors Actuators B Chem. 2015;213:515–33.

Y. Han, J. Zheng, and S. Dong, “A novel nonenzymatic hydrogen peroxide sensor based on Ag–MnO2–MWCNTs nanocomposites,” Electrochim Acta, 90, 35–43 (2013). G. Fan, “Highly sensitive electrochemical determination of cadmium (II) in environmental water based on the electrodeposited bismuth nanoparticles,” Int J Electrochem Sci, 4362–4370 (2016).

Kan X, Zhao Y, Geng Z, Wang Z, Zhu J-J. Composites of multiwalled carbon nanotubes and molecularly imprinted polymers for dopamine recognition. J Phys Chem C. 2008;112:4849–54.

Lee S, Oh J, Kim D, Piao Y. A sensitive electrochemical sensor using an iron oxide/graphene composite for the simultaneous detection of heavy metal ions. Talanta. 2016a;160:528–36.

Lee SM, Zirlianngura JA, Tiwari D. Electrochemical sensor for trace determination of cadmium(II) from aqueous solutions: use of hybrid materials precursors to natural clays. Int J Environ Anal Chem. 2016b;96:490–504.

Legeai S, Vittori O. A Cu/Nafion/Bi electrode for on-site monitoring of trace heavy metals in natural waters using anodic stripping voltammetry: an alternative to mercury-based electrodes. Anal Chim Acta. 2006;560:184–90.

Martínez-Huitle CA, Fernandes NS, Cerro-Lopez M, Quiroz MA, Quiroz MA. Determination of trace metals by differential pulse voltammetry at chitosan modified electrodes. Port Electrochim Acta. 2010;28:39–49.

Mazzotta E, Malitesta C. Electrochemical detection of the toxic organohalide 2, 4-DB using a Co-porphyrin based electrosynthesized molecularly imprinted polymer. Sensors Actuators B Chem. 2010;148:186–94.

Mhammedi MAE, Achak M, Hbid M, Bakasse M, Hbid T, Chtaini A. Electrochemical determination of cadmium(II) at platinum electrode modified with kaolin by square wave voltammetry. J Hazard Mater. 2009;170:590–4.

Parameswaran G, Mathew B. Bioremediation of waste water containing hazardous cadmium ion with ion imprinted interpenetrating polymer networks. Adv Environ Chem. 2014;2014:1–10.

Parham H, Pourreza N, Rahbar N. Solid phase extraction of lead and cadmium using solid sulfur as a new metal extractor prior to the determination by flame atomic absorption spectrometry. J Hazard Mater. 2009;163:588–92.

Rezaei B, Rahmanian O. Direct nanolayer preparation of molecularly imprinted polymers immobilized on multiwalled carbon nanotubes as a surface-recognition sites and their characterization. J Appl Polym Sci. 2011;125:798–803.

Roy E, Patra S, Madhuri R, Sharma PK. Simultaneous determination of heavy metals in biological samples by a multiple-template imprinting technique: an electrochemical study. RSC Adv. 2014;4:56690–700.

Shen J, Hu Y, Qin C, Ye M. Layer-by-layer self-assembly of multiwalled carbon nanotube polyelectrolytes prepared by in situ radical polymerization. Langmuir. 2008;24:3993–7.

M. P. Sooraj and B. Mathew, “Structure-specific sorbent based on nanostructures for selective recognition of cimetidine from its structural analogues,” J Appl Polym Sci, 131, (2014).

A. Trani, R. Petrucci, G. Marrosu, D. Zane, and A. Curulli, “Selective electrochemical determination of caffeine at a gold-chitosan nanocomposite sensor: may little change on nanocomposites synthesis affect selectivity?,” J Electroanal Chem, 788, 99–106 (2017).

Veerakumar P, Veeramani V, Chen S-M, Madhu R, Liu S-B. Palladium nanoparticle incorporated porous activated carbon: electrochemical detection of toxic metal ions. ACS Appl Mater Interfaces. 2016;8:1319–26.

Waalkes M. Cadmium carcinogenesis. Mutation Research/Fundamental and Molecular Mechanisms of Mutagenesis. 2003;533:107–20.

Wei Y, Gao C, Meng F-L, Li H-H, Wang L, Liu J-H, Huang X-J. SnO2/reduced graphene oxide nanocomposite for the simultaneous electrochemical detection of cadmium(II), lead(II), copper(II), and mercury(II): an interesting favorable mutual interference. J Phys Chem C. 2012;116:1034–41.

Wong A, Foguel MV, Khan S, de Oliveira FM, Tarley CRT, Sotomayor MDPT. Development of an electrochemical sensor modified with MWCNT-COOH and MIP for detection of diuron. Electrochim Acta. 2015;182:122–30.

Zougagh M. Determination of cadmium in water by ICP-AES with on-line adsorption preconcentration using DPTH-gel and TS-gel microcolumns. Talanta. 2002;56:753–61.

Acknowledgements

The analytical facilities from Cashew Export Promotion Council of India, Kollam, Kerala, is gratefully acknowledged.

Funding

There is no funding for this study.

Availability of data and materials

The authors have no data to share since all data are revealed in the submitted manuscript.

Author information

Authors and Affiliations

Contributions

MWCNT-based ion-imprinted polymer used as an electrochemical sensor and sorbent for toxic Cd(II) ions from real samples was discussed in this paper. Both authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing interests.

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Aravind, A., Mathew, B. Tailoring of nanostructured material as an electrochemical sensor and sorbent for toxic Cd(II) ions from various real samples. J Anal Sci Technol 9, 22 (2018). https://doi.org/10.1186/s40543-018-0153-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40543-018-0153-1