Abstract

Over the years, numerous gold and silver artifacts were excavated from tombs of the Tang Dynasty which gave evidence of the sophisticated metalworking techniques at that time. However, very few of them were studied and the manufacturing process was barely known. In this research, the microstructural analyses including microscopy and SEM–EDS were conducted on a delicate silver cosmetics box excavated from a Tang Dynasty tomb of Xiaolizhuang site. The silver artifact is made up of two symmetrical cambered pieces which were fabricated by alternating hammering and annealing. The shape and surface features were further modified through plastic forming. Afterwards, spinning technique was employed to ensure the interior surface is smooth and has consistent thickness. The surface of the silver box is fully decorated with multiple fine engraving including petals, fish-toe circles, flower pattern, twine pattern and the Tang grass pattern. According to the overlapping status of the notches, the patterns were processed in a certain order by using various gravers. The artifact was brought in its final appearance by gilding to form a thin gold film on the surface. These results overall reveal the sophisticated techniques applied in making the artifact and further enhance the understanding of metalworking practices in the Tang Dynasty.

Similar content being viewed by others

Introduction

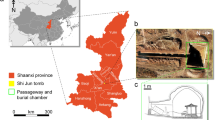

Located in Baofeng County, Henan province, Xiaolizhuang site occupies approximately 1000,000 m2 of land and was listed as one of the national protective heritage sites in 2013. With a 4600 years history, Xiaolizhuang site reserves numerous ancient ruins dating from the Neolithic Age to the Northern and Southern Dynasties (AD 420–589). The first excavation of the site was carried out in 2008 which unearthed various cultural relics including potteries, ceramics, copper wares, iron wares, stone wares, bone artifacts, etc. In 2017, the second excavation was performed jointly by Pingdingshan Bureau of Cultural Relics and University of Zhengzhou. A Tang Dynasty tomb was discovered by coincidence for the first time. It was initially overlooked due to its low status appearance and the difficulty in identifying the female tomb owner due to the damaged epitaph. Only a few potteries, bronze and iron utensils were extracted along with several metal accessories such as hairpins. Among them, a delicate silver artifact which appeared to be a female cosmetics case drew the attentions of the archaeologists. The silver case exhibits a diameter of approximately 3.3 cm and height of 1.55 cm. It consists of two symmetrical pieces of flower-shaped silver and locked by a buckle. The surface is fully decorated with multiple fine carvings which were likely made by experienced silversmith. In the Tang Dynasty, potteries, bronze and iron wares were available to a wide range of people, however, silver objects especially the elaborate ones were reserved for elites to represent their high social status [1]. In other words, the owner of this silver artifact was likely to be a woman of high social status which leaves behind a mystery on the tomb owner’s identity.

Silver is one of the precious metals used by early civilizations to produce ornaments, jewelry and coins, therefore, silver artifacts represent the material cultural heritage of certain periods [2]. Numerous studies of ancient silver artifacts were reported in scientific literatures. The main areas of research are the investigation of provenance [3,4,5], chemical composition and microstructure [6,7,8,9,10] and manufacturing processes [1, 11,12,13]. In ancient China, the sophistication and the technical skills in metalworking of gold and silver artifacts reached its peak in the Tang Dynasty. According to the literatures [14, 15], the various techniques include primarily casting, hammering and annealing, plastic forming, engraving, embossing, granulation, joining techniques and gilding [10, 16, 17]. In general terms, shaping was the basis of metalworking which commonly achieved by utilizing hammering or casting. During the processes of hammering, repeated hammering and annealing were applied to flatten silver metal into desire form [11, 12] and consequent plastic forming was employed to further modify the shape. In addition to hammering, casting was a popular method that involved using a certain mould to form the desired shape of the object. It is believed that the western style hammering was introduced to China in the Tang Dynasty which advanced the local metalworking techniques [18]. Since then hammering presumably became more prevalent than casting in the manufacturing process. After the completion of shape, engraved decorations were subsequently made on the surface of the item by utilizing a set of gravers. To finalize the artifact, gilding was sometimes applied to leave a shiny appearance.

Apart from the written source, numerous silver artifacts were excavated from tombs of the Tang Dynasty over the years. Some limited studies with focusing on the surface design [19,20,21,22,23,24,25] and chemical composition [6] were performed, however, the surface features and manufacturing marks that essential for understanding the metalworking techniques [13] were often overlooked. Tan’s team has done a great job on studying the silver artifacts from the Wei family tomb of the Tang Dynasty [26]. The research provided information on the material features and manufacturing techniques in making those silver wares. However, various metalworking techniques might be used in the Tang Dynasty, it requires more homogeneous studies to reveal the sophisticated skills. In this paper, the microstructural analyses were conducted on the silver artifact excavated from the Tang Dynasty tomb of Xiaolizhuang site. Since sampling is strictly forbidden, the noninvasive approach including microscopic analysis and SEM–EDS analysis was employed to identify both the microstructure of the silver box and the elemental compositions. The metalworking techniques including hammering, plastic forming, engraving and gilding were proved to be used in making the artifact. The results overall provide direct source in understanding the metalworking of silver in the Tang Dynasty.

Materials and methods

Sample

The silver artifact that excavated from the Tang Dynasty tomb of Xiaolizhuang site (in Fig. 1) was studied in this paper.

Microscopic analysis

Microscopic studies were performed on a KEYENCE VHX-2000C microscope. The images were captured by using an in-built software.

SEM–EDS analysis

Microstructure and the elemental compositions were collected by the secondary electron imaging and backscattered electron imaging under SEM–EDS with a Phenom XL equipment at 10 kV for 20 s acquisition.

Results and discussion

Morphology analysis

As shown in Fig. 2a, the silver artifact which presents the eight-petaline flower form is made up of two symmetrical cambered pieces. The multiple engraved decorations including fish-roe circles, flower pattern and twine pattern are distributed symmetrically on the front surface with some overlapping textures. While further magnified in Fig. 2b, the eight cross-cutting lines which outline the petals are observed at the center of the surface. The deviation found at the intersection was resulted from the manual error of the silversmith. As observed in Fig. 2c, eight pairs of the Tang grass pattern are circled on the shoulder of the object. The upper and bottom rims are embordered with silver loops (approximately 0.6 mm in thickness) to highlight the frame. In Fig. 2d, the interior surface exhibits the legible processing marks for shaping the petaline embossment. The petals present almost the same shape and dimensions.

Analysis of the shaping and engraving techniques

Solid metal can be processed through cycles of cold working and heating, which also known as hammering and annealing to form desired shape and dimensions. Repeated heating and annealing brings the benefits of low deformation resistance and good plastic property. As shown in Fig. 2d, the hammering marks (pointed out by the arrows) are observed on the interior surface. As demonstrated in the SEM image in Fig. 3, the recrystallized structure is observed which gives evidence of annealing. Annealing with the aim to increase the ductility of the metal would benefit the consequent processes.

The SEM images in Fig. 4a further present the annular marks on the interior surface of the silver box. It is inferred to be resulted from spinning in comparing with the similar marks that found on the silver bowl and silver box of Hejia County (as indicated in Fig. 4b).

Spinning marks that found on the interior of the silver box (a), in comparing with the similar marks on the silver box of Hejia county [27]

Once the shape was formed, the engraved decorations were produced on the surface of the artifact. In Fig. 5a, it is observed from the notches (highlighted by red dots) that the shade-lines of fish-toe circles are interrupted and overlaid by that of flower pattern. The flower pattern and the fish-toe circles are then overlapped by the shade-lines of the petal. The overlaying details observed in Fig. 5b further illustrate the sequence in making the patterns. The route of the pattern could be identified from A to B. It is clear that the fish-toe circles were made prior to the flower pattern and the petals were drawn afterwards. The diameters of the fish-toe circles were measured at 0.2 mm in average, which may indicate the use of bead-carving graver in producing the fine and dense circles. The flower pattern was made stroke by stroke using approximately the flat-headed graver to avoid crack. The visible notch observed in Fig. 5c suggests the use of straight-headed graver to draw the lines of the petal. Overall, these patterns consist of smooth and rounded shade-lines (indicated as C and D in Fig. 5b) were likely made by sophisticated silversmith. However, since manual error is inevitable, several minor flaws that resulted from overexertion were noticed.

To smooth the rim and further ensure the sealing property of the artifact, the rim was embordered with bended silver foil. Owing to the ductility, the silver metal was stretched into thin foil (width: approximately 0.6 mm) and then bended into loop to warp the rim simultaneously cover the joints.

Analysis of the gilding technique

The entire surface of the artifact especially the locations of the notches exhibit a gold and shiny appearance. The elemental compositions of the selected points were determined by EDS analysis and the results are provided in Table 1. The high contents of Au with the lower contents of Ag and Hg were detected on the surface of the artifact, suggests the application of gilding. And the minor contents of Si were presumably resulted from contaminations. Gilding is a technique with the aim to leave a gold appearance on the metal surface. It is made by applying amalgam (a mixture of gold and mercury) onto the surface of silver or copper and consequent by heating to retain the thin film of gold with removing mercury [28,29,30]. Therefore, the existence of Hg gives evidence of gilding treatment that has done on the entire surface of the silver box. The higher content of Ag identified on the shoulder of the item indicate the relatively thin layer of gold. Moreover, the irregular surface of the artifact caused the differences in the detected contents of mercury, where the notches retain the higher contents of Hg. As shown in Fig. 6, the gray level indicates various distributions of the elements where the bright region represents the obvious higher contents of Au and Hg.

In addition, the central part of the interior surface with fine metallic luster and less oxidation was selected to determine the elemental composition of the raw metal, and the rim was also analyzed from both interior and exterior. Referring to the results in Table 2, the raw material is identified as highly purified silver mixed with minor gold and copper. The dark areas shown in the backscattered electron image represent the oxidation products of silver. The elemental compositions identified from the rim are close to that of the body material. Since gilding was applied only on the exterior surface, Hg was not detected on the interior surface as well as the rim from inside. However, Hg was detected on the rim from outside. It suggests that gilding was applied as the last step after the modification of the rim.

Discussion

The microstructure of metal object is affected by material difference and distinct metalworking techniques (hammering or casting). In other words, the microstructure of metal artifact can explain the type of work that has done. In this research, the above microstructural analyses revealed that related metalworking techniques were involved in the manufacturing of the silver artifact, including hammering and annealing, plastic forming, engraving and gilding. At the first stage, the ingot-shaped silver metal was processed upon many cycles of hammering and annealing to form two symmetrical cambered pieces. The striking marks observed on the interior surface of the artifact give the evidence of hammering, and the signs of recrystallization indicate annealing was employed to improve the ductility of the metal. Hammering is the technique that remodels the metal through repeated striking and knocking, along with annealing to form the desired shape and thickness [11, 12]. The metal needs to be fixed on an elastic cushion (normally made from the mixture of rosin, talcum powder and plant oil) to alleviate the hammering force, and operated by using various hammers and anvils. The metal was flattened by hammering to obtain a thin sheet and cut into round shape. It was then modified through plastic forming (hammering and notching) to allow bending to achieve the cambered shape. The central area was hammered to form the stereoscopic shape of eight petals surrounded by oval embossments. Comparing with casting, the technique of hammering and annealing is more flexible in shaping and performs better on material saving. Afterwards, spinning was employed to ensure the cambered pieces are smooth and have consistent thickness which also left the annular marks on the interior surface of the silver box. It is inferred that the spinning technique of the Tang Dynasty was similar as the metal spinning technique that employed in medieval Europe [31].

Once the primary shape of the artifact was formed, the multiple engraved decorations including petals, fish-toe circles, flower pattern, twine pattern and the Tang grass pattern were produced on the exterior surface. The eight-petaline flower is a traditional symmetrical pattern that widely used in the decoration of bronze mirror. And the design of fish-toe circles derives from fish scale. Flower pattern and twine pattern are also the traditional decorations that commonly found in painting of porcelain. The Tang grass pattern was a prevalent decorative pattern in the Tang Dynasty that imitates the branch and leaf of peony. Referring to the microstructure of the artifact, it is clear that these patterns were made in a certain order. For instance, it is observed that the shade-lines of the fish-toe circles are interrupted by the flower pattern and they are both overlaid by the lines of the petals. The overlapping status of the notches indicates that the fish-toe circles were made prior to the flower pattern and the outlines of the petals were engraved afterwards. To ensure the smoothness and coherence of the shade-lines, various tools including bead-carving graver, flat-headed graver and straight-headed graver were possibly employed in drawing the patterns. Without help of magnifying tool, it requires sophisticated skills to do the work since the engraved decorations were made purely relying on the experience of the artisan.

In completion of the entire shaping, the rough rim was modified by embroidering with bended silver foils. The bar-shaped silver metal was stretched into thin foil and bended to form a loop. The silver loop was then fixed onto the rim to cover the rough edge and further ensure the sealing property between the upper and lower plates.

At the final stage, gilding was applied to form a gold and shiny film on the finished artifact. In ancient times, amalgam fire gilding was known as the most sophisticate but less expensive technique to coat metal objects with thin gold film [30]. It is done by gently brushing amalgam paste (mixture of gold and mercury) on the metal surface and consequent by thermal treatment to remove mercury. Even minor amount of mercury would be retained, the artifact will be covered with a gold and shiny film [30]. According to the analytical results, the high content of Au and minor Hg that detected on the exterior surface of the artifact prove the use of gilding. However, the irregular surface of the artifact gave rise to the uneven thickness of the gold film.

Over the years, numerous silver artifacts of the Tang Dynasty were excavated including several delicate silver cases with various dimensions and shapes that produced through sophisticated manufacturing procedures and techniques. Majority of them were found in Xi’an where the capital city of the Tang Dynasty located. Among them the silver box named “du guan qi ge guo” (in charge of the seven countries) as shown in Fig. 7a is recognized as a royal treasure that represents the sophisticated technological skills of the late Tang Dynasty [32]. In view of the symmetrical petaline shape and buckle locking form, it is similar to that of the artifact of Xiaolizhuang site. In addition, the same metalworking techniques such as hammering, engraving and gilding were used in making the object. However, its surface decorations were made in various ways. The people and animal embossing were casted on the front cover while the twine patterns were engraved on the shoulder of the artifact. Therefore, it probably required less engraving skills but more casting techniques than that of the investigated object. On the other hand, the gilded silver box collected from the Wei family tomb (as shown in Fig. 7b) was also found with hammering and engraving marks [26], but its shape and decorations are much easier to form than that of the artifact of Xiaolizhuang site. Another example is a small gilded silver box that unearthed in Hongqing County (as shown in Fig. 7c) which was embossed with fine decorations [22], however, the metalworking remains unknown due to a lack of microstructural study. Overall, these delicate artifacts give evidence of the sophisticated metalworking techniques that used in the Tang Dynasty. And most of the techniques are proved to be applied in making the artifact of Xiaolizhuang site. Therefore, the investigated silver box is reckoned to be a representative of the sophisticated metalworking practices of the Tang Dynasty.

Silver cases of the Tang Dynasty that excavated in Xi’an (a gilded silver box named “du guan qi ge guo” unearthed in the campus of Xi’an Jiaotong University [25]; b gilded silver box decorated with engraving of lying deer found in the Wei family tomb [26]; c small gilded silver box unearthed in Chongqing County [22])

Conclusions

In ancient times, silver was a precious metal used by early civilization to produce coins, jewelry and ornaments. It is recorded in the history of China that silversmiths of the Tang Dynasty possessed the most sophisticated metalworking skills. In this research, a delicate silver artifact excavated in the Tang Dynasty tomb of Xiaolizhuang site was studied through microstructural analyses. The nondestructive approach including microscopic analysis and SEM–EDS analysis was employed to identify the microstructure and the elemental compositions of the artifact. The metalworking techniques including hammering, plastic forming, engraving and gilding are proved to be used in the manufacturing processes and completed by skilled silversmith. In comparing with the other silver artifacts of the Tang Dynasty, the investigated object is reckoned to be a representative artifact that exhibits the sophisticated techniques of the Tang Dynasty. This research overall enhances the understanding of metalworking practices in the Tang Dynasty.

Availability of data and materials

All data generated or analyzed during this study are included in this article.

Abbreviations

- SEM–EDS:

-

scanning electron microscope energy–dispersive spectrometry

References

Hörz G, Kallfass M. The treasure of gold and silver artifacts from the Royal Tombs of Sipán, Peru—a study on the Moche metalworking techniques. Mater Charact. 2000;45:391–420. https://doi.org/10.1016/S1044-5803(00)00093-0.

Vassiliou P, Novakovic J, Ingo GM, De Caro T. Corrosion of ancient silver alloys. In: 17th International Corrosion Congress 2008: Corrosion Control in the Service of Society; 2008.

Hajivaliei M, Mohammadifar Y, Ghiyasi K, Jaleh B, Lamehi-Rachti M, Oliaiy P. Application of PIXE to study ancient Iranian silver coins. Nucl Instrum Methods Phys Res Sect B Beam Interact Mater Atoms. 2008;266(8):1578–82. https://doi.org/10.1016/j.nimb.2007.12.101.

Wood JR, Charlton MF, Mercedes MB, Marcos MT. Gold parting, iridium and provenance of ancient silver: a reply to Pernicka. J Archaeol Sci. 2017;86:127–30. https://doi.org/10.1016/j.jas.2017.07.005.

Wood JR, Charlton MF, Mercedes MB, Marcos MT. Iridium to provenance ancient silver. J Archaeol Sci. 2017;81:1–12. https://doi.org/10.1016/j.jas.2017.03.002.

Wei CL, Fan QM, Liu YW, Li DL. X-ray fluorescence analysis of the silver content of ancient Chinese silverware. X-Ray Spectrom. 1996;25:138–9. https://doi.org/10.1002/(SICI)1097-4539(199605)25:3%3c138:AID-XRS157%3e3.3.CO;2-N.

Caridi F, Sabatino G, Mezzasalma AM, Faenza P, Castrizio ED. Spectroscopic analyses of an ancient silver fragment of the reliquary bust of St. Leo. Radiat Effects Defects Solids. 2014;169(7):573–83. https://doi.org/10.1080/10420150.2014.931403.

Sándor ZS, Tölgyesi S, Gresits I, Kasztovszky ZS. Determination of the alloying elements in ancient silver coins by X-ray fluorescence. J Radioanal Nucl Chem. 2002;254(2):283–8. https://doi.org/10.1023/a:1021667731404.

Vasilescu A, Constantinescu B, Stan D, Radtke M, Reinholz U, Buzanich G, Ceccato D. Studies on ancient silver metallurgy using SR XRF and micro-PIXE. Radiat Phys Chem. 2015;117:26–34. https://doi.org/10.1016/j.radphyschem.2015.07.008.

Oudbashi O, Shekofteh A. Chemical and microstructural analysis of some Achaemenian silver alloy artefacts from Hamedan, western Iran. Periodico Di Miner. 2015;84(3A):419–34. https://doi.org/10.2451/2015PM0022.

Ashkenazi D, Gitler H, Stern A, Tal O. Metallurgical investigation on fourth century BCE silver jewellery of two hoards from Samaria. Sci Rep. 2017. https://doi.org/10.1038/srep40659.

DeVries MF, Thmosen HH, Thomsen EG. The manufacture of an ancient silver bowl. J Appl Metalwork. 1980;1(3):52–60. https://doi.org/10.1007/BF02833905.

Angelini E, Batmaz A, De Caro T, Faraldi F, Grassini S, Ing GM, Riccucci C. The role of surface analysis in the strategies for conservation of metallic artefacts from the Mediterranean Basin. Surf Interface Anal. 2014;46(10–11):754–63. https://doi.org/10.1002/sia.5512.

Yang XL. Fine workmanship—crafts and cultural relics. Beijing: Science Press; 2008 (in Chinese).

Xu XD, Yang JC. Ancient Chinese crafts of gold processing. Hong Kong: Chinese University of Hong Kong; 2017 (in Chinese).

Untracht O. Jewelry concepts and technology (Ch. 9). London: Robert Hale Limited; 2007.

Schorsch D. Silver-and-gold moche artifacts from Loma Negra, Peru. Metrop Mus J. 1998;33:109–36. https://doi.org/10.2307/1513009.

Yang BD. Discussion on the denomination of the pattern carving crafts used in making Chinese gold and silver wares. Palace Mus J. 1995;4:15 (in Chinese).

An YX. Discovery of gold-and silverware unearthed from an ancient tomb at Zhaosu County, Yili, Xinjiang. Cult Relics. 1999;9:4–15 (in Chinese).

Liu JG, Liu X. The silverwares of the Tang Dynasty that unearthed from Dingmaoqiao, Dantu, Jiangsu province. Cult Relics. 1982;11:15–28 (in Chinese).

Lu JG, Liu JG. Analysis of the silverwares that unearthed from Dingmaoqiao, Dantu. Cultural Relics. 1982;11:28–34 (in Chinese).

Yan L. Gold and silver wares of the Tang Dynasty that unearthed in Xi’an. Cult Relics. 1959;8:34–5 (in Chinese).

Bao Q. Gold and silver wares of the Tang Dynasty that unearthed in the suburbs of Xi’an. Archaeol Cult Relics. 1984;4:27–9 (in Chinese).

Wang CQ. Gold and silver wares of the Tang Dynasty that unearthed in Xi’an and their decorative and artistic features. Relics Museol. 1992;3:20–33 (in Chinese).

Wei C. A precious silverware of the Tang Dynasty: the hexapetalus silver box named “du guan qi ge guo”. Collectors. 2003;7:15–7 (in Chinese).

Tan PP, Yang JC, Li XC. An analysis and preliminary research on the silver wares unearthed from the Wei family tomb of the Tang Dynasty in Xi’an, China. Qian Ling Cult Res. 2014;00:38–49 (in Chinese).

Chen SX, Xiong XM. Textual research on the use of spinning technique in ancient China. Stud Hist Nat Sci. 1985;4(4):342–4 (in Chinese).

Rifai MM, El Hadidi NMN. Investigation and analysis of three gilded wood samples from the tomb of Tutankhamun. In: Dawson J, Rozeik C, Wright MM, editors. Decorated surfaces on ancient Egyptian objects, technology, deterioration and conservation. United Kingdom: Cambridge; 2010. p. 16–24.

Sandu ICA, Murta E, Veiga R, Muralha VSF, Pereira M, Kuckova S, Busani T. An innovative, interdisciplinary, and multi-technique study of gilding and painting techniques in the decoration of the main altarpiece of Miranda do Douro Cathedral (XVII–XVIIIth centuries, Portugal). Microsc Res Tech. 2013;76(7):733–43. https://doi.org/10.1002/jemt.22224.

Ingo GM, Riccucci C, Pascucci M, Messina E, Giuliani C, Biocca P, Tortora L, Fierro G, Di Carlo G. Combined use of FE-SEM + EDS, ToF-SIMS, XPS, XRD and OM for the study of ancient gilded artefacts. Appl Surf Sci. 2018;446:168–76.

Wu KY. Gilding. Chin J Hist Sci Technol. 1981;1:90–5 (in Chinese).

Liang XQ. More argument on the six-petal silver box in seven governed countries. J Qujing Norm Univ. 2010;29(5):81–7 (in Chinese).

Acknowledgements

We are thankful to Feng Li from School of Archaeology, Zhengzhou University for providing the sample. The technical support from Zhengzhou University is greatly appreciated.

Funding

There is no funding supported for this research.

Author information

Authors and Affiliations

Contributions

ZY analyzed and interpreted the patient data. YG performed the examination and was a major contributor in writing the manuscript. Both authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated.

About this article

Cite this article

Yao, Z., Gong, Y. Study on a silver box unearthed from the Tang Dynasty (AD 618–907) tomb at Xiaolizhuang Site, Henan Province, China. Herit Sci 7, 72 (2019). https://doi.org/10.1186/s40494-019-0315-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40494-019-0315-5