Abstract

BaHfO3 (BHO) has been proposed as a new cap layer material for YBa2Cu3O7−δ (YBCO) coated conductors. Highly c-axis oriented BHO cap layer has been deposited on ion-beam assisted deposition-MgO buffered Hastelloy tapes by direct-current-magnetron sputtering method. The epi-growth of BHO films combined with its properties is investigated in details. The degenerated cubic crystal structure of BHO film is confirmed by Raman spectrum analysis. XRD θ–2θ scan, φ-scan and ω-scan reveal an excellent c-axis alignment with good in-plane and out-of-plane textures for BHO cap layers. SEM and AFM investigations show BHO cap layer a dense and crack-free morphology. Subsequently pure c-axis orientation YBCO film was epitaxial grown on such BHO cap layer successfully, shown BaHfO3 a potential cap layer material for coated conductors.

Similar content being viewed by others

Background

Due to their high performance and the potential low cost of both raw materials and preparation techniques, coated conductors based on the high temperature superconductors REBa2Cu3O7−δ (REBCO or RE123; RE = Y, Nd, Sm or other rare earth elements) are expected to be practical materials application at liquid nitrogen temperature. To overcome the weak link behavior of the RE123 grain boundaries and achieve high performance coated conductors, the basic requirement is to realize RE123 films texture on flexible substrates. Main techniques to achieve the required biaxially textured RE123 superconducting layer include the rolling assisted biaxially textured substrates (RABiTS) (Goyal et al. 1996; Norton et al. 1996; Hühne et al. 2007), ion beam assisted deposition (IBAD) (Iijima and Matsumoto 2000; Muroga et al. 2003) and inclined substrate deposition (ISD) (Ma et al. 2004). Compared with RABiTS technique which needs metal substrate a texture structure first, IBAD technology can form the textured films on non-textured polycrystalline metal substrates and is used in worldwide.

Typically, coated conductor architecture includes three layers: the metallic substrate, the buffer layers and the RE123 superconductor layers. The buffer layers on the metallic substrate have two main functions for coated conductors based on the IBAD technique: (1) to form the texture structure and transfer the texture to the epi-grown RE123 superconductor layers; (2) to act as a barrier and prevent Ni or O atoms diffusion during the RE123 processing at high temperature.

Different oxide materials, including LaMnO3 (Aytug et al. 2003), CeO2 (Bhuiyan and Paranthaman 2003), SrTiO3 (Sathyamurthy and Salama 2002) and TiN (Xiong et al. 2010), have been successfully used as buffer layers to fulfill these requirements. Although the mechanism is not clear, it was found that different cap layer properties including material, texture or surface morphology affect subsequently RE123 epi-growth and performance seriously (Wang et al. 2004). Development of new cap layer material is helpful to understand these influences.

Recently, BaHfO3 was found exist stably in RE123 films and was researched as a dope to improve the superconductivity properties of coated conductor films (Erbe et al. 2015). Moreover, no significant reaction between YBCO and BaHfO3 was detected up to YBCO melt temperature about 1060 °C in melt-texture growth technique (Zhang and Evetts 1994). In this case, BHO was thought to be an excellent cap layer material for coated conductors. In this paper, BaHfO3 was deposited on IBAD-MgO buffered Hastelloy substrate as cap layer via DC-magnetron sputtering technique. The biaxially textured BHO cap layer shows a dense, smooth, and crack-free morphology. Finally the YBCO films were epitaxially grown on the BHO cap layer via pulsed laser deposition (PLD) method, shown BHO a new potential buffer material.

Experiments

Hasterlloy tapes were electro-polished to a surface roughness less than 2.0 nm and then used as metal substrate. None crystallized Al2O3 and Y2O3 were deposited by Ion-Beam technique at room temperature as barrier layer and seed layer, respectively. MgO template layers were then deposited by ion beam assisted deposition technique (IBAD) to form the biaxial texture.

BaHfO3 (BHO) layers were then epi-grown on such MgO buffered tapes in a reel-to-reel magnetron sputtering system to form BHO/IBAD-MgO/Y2O3/Al2O3/Hastelloy structure. Metal Barium (99.9%) and Hafnium (99.95%) spliced with area ratio about 1:1 were used as metal targets for BHO cap layers deposition. The BHO was deposited in Ar/O2 mixture atmosphere with a total background pressure of 1 Pa and an oxygen partial pressure of about 0.15 Pa. The thickness of BHO films are about 40–50 nm, which are measured with a surface profiler (DEKTAKXT, Bruker Corporation).

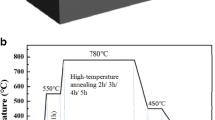

After that, typical 300 nm thick YBCO films were epi-grown by pulsed laser deposition (PLD) method to check up the performance of the BHO cap layers with a substrate temperature of 810 °C, a background oxygen pressure of 30 Pa and an oxygen loading step under 4 × 104 Pa during cooling down. More details can be found elsewhere (Hühne et al. 2007; Ying et al. 2009).

Raman scattering experiments were performed in back-scattering geometry using a Spex 1403 double monochromator equipped with a RC31034 photomultiplier and photocounting system to character the fabricated BHO films and analysis their crystal structure. A Spectra-Physics 171 argon ion laser with a 488 nm laser line was served as the excitation source at an incident power of 10 mW on samples.

To evaluate the textures and the orientation of BHO and YBCO films, X-ray diffraction (XRD, Philips X’Pert PRO, Cu Kα, λ = 1.54185 Å) analysis including θ–2θ scan, φ-scan, and rocking curve were performed. The surface morphology and micro-structures of the BHO films were investigated by Scanning Electron Microscope (SEM, Apollo 300) and Atomic Force Microscopy (AFM, Nanofirst 3600A), respectively. The critical current density Jc of the YBCO coated conductor was examined by inductive measurement using a Cryoscan by Theva.

Results and discussion

Different substrate temperatures ranging from 700 to 900 °C were used to evaluate the epitaxial growth of BaHfO3 on IBAD-MgO buffered substrate. Figure 1 shows the typical θ–2θ XRD pattern of BaHfO3 cap layers. They demonstrate that no additional phases are formed except the desired BHO films. Only BHO (001) and BHO (002) diffraction peak were visible. The BHO films show (001) reflections only indicating a strong (001) texture for all substrate temperatures investigated. Additionally, the intensity ratio of I BHO (002) and I Hast (220) reflections is calculated to evaluate the growth of BHO films, shown in the inset. The ratio of I BHO (002)/I Hast (220) increases with substrate temperature rise, which is an indication for an improved crystallinity of the BHO films grown and better orientation at higher temperatures. As the substrate temperature is higher than 900 °C, the value of I BHO (002)/I Hast (220) is decreased, which should be caused by the mis-orientation of BHO films. Thus, the optimized substrate temperature about 800 °C should be benefit for BHO films epi-growth.

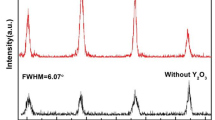

Since the lattice parameters of BaHfO3 and MgO are almost similar, it is difficult to distinguish between them in the X-ray diffraction patterns. To confirm the fabrication of BHO and analyse their crystal structure, the Raman scattering experiments are then performed at room temperature, shown in Fig. 2.

According to group theory, an ideal cubic perovskite structure crystal has six selection rules and symmetry species of the fundamental modes, including 3F1u + F2u. The F2u mode is silent and the F1u modes are only infrared active, so there should be no first-order Raman active mode for AETO3 crystals in cubic perovskite structure (AE = Ca, Sr and Ba, T = Hf an Zr, space group Pm3m) at room temperature (Karan et al. 2009). Park et al. (1976) found that a distortional noncubic perovskite structures could happen for both CaTO3 and SrTO3 but not for BaTO3 (T = Hf and Zr). In this case, first-order Raman bands are allowed for CaTO3 and SrTO3. Further research found that this degenerated perovskite structures can also happen in BaZrO3 by Ti doping. In this degenerated noncubic structures each of the F1u modes split into two E modes and one A1 mode, and the F2u mode split into one E and two B1 modes. All the A1 and E modes are both Raman and infrared active and the B1 mode is a Raman active (Xie and Zhu 2012).

From Fig. 2, the over damped transverse E1 mode combined with other E1 and A1 Raman modes are obviously detected, located at 145.0, 559.4 and 694.5 cm−1, respectively, indicating a degenerated noncubic structures for BaHfO3 cap layer films. The sharp A1 modes at 145 and 559.4 cm−1 are arisen from the interference of the strong anti-resonance effect, which have been attributed to rotational vibrations associated with the polar BaO6 octahedra. Another sharp A1 mode is also detected at 694 cm−1, which is attributed to symmetric stretching mode vibrations associated with O atoms. Thus by the observation of the first-order Raman scattering, which is forbidden in a perfect cubic structure, the BHO cap layer films distortions away from the ideal cubic structure are evidenced. This may be caused by the presence of three-dimensional stress from the multi-films system. This stress induced structure degeneration is also occurred in CeO2 buffered on Ni–5 at.% W substrate (Lu et al. 2015).

Surface morphologies are important for subsequent epi-growth of YBCO films. The surface morphologies of BHO films deposited at different substrate temperature are characterized by AFM and SEM, shown in Fig. 3. From AFM images, smooth, crackfree, pinholefree and compact surface morphologies of BHO films are observed, which should be suitable for subsequently YBCO film epi-growth. The BHO film deposited at 850 °C achieved a relatively smooth surface morphology, with a root mean square surface roughness (RMS) values about 2.7 nm within 5 × 5 μm2 area. From SEM image, the morphologies of BHO films are confirmed to be smooth, crack-free and compact. Some particles in line arrange are caused by the crystal boundaries of Hastelloy metal substrate. Energy dispersive X-Ray spectroscopy (EDX) examination shows the atomic ratio of Ba to Hf is about 1.3, confirming the formation of BHO phase, which is corresponded well with the results of XRD pattern and Raman spectrums.

The in-plane and out-of-plane texture of BHO films are checked by XRD φ-can and ω–scan, respectively. Figure 4 shows the φ-scan of BHO films deposited at different temperature and the dependence of FWHM values on deposition temperature. The optimized in-plane texture could be achieved at 850 °C, which is fitted well with the results of XRD pattern. The out-of-plane full width at half-maximum (FWHM) values of ω-scan about 3.2° reveal that the BHO films exhibit a strong biaxial texture, indicating BHO a potential cap layer material for YBCO coated conductor.

In the next step, typical 300 nm thick YBCO thin films were deposited on the BHO cap layer by PLD to investigate the performance of this coated conductor architecture. The epitaxial relationship of the YBCO layer towards the used BHO template was investigated by XRD θ–2θ pattern and φ-scan measurements, shown in Fig. 5.

From the θ–2θ XRD pattern of the YBCO film, only YBCO (001) diffraction peak could be detected, showing the YBCO film a well c-axis orientation on such BHO/IBAD-MgO/Y2O3/Al2O3/Hastelloy buffer structure. Inset of Fig. 5 shows the (103) φ-scan of the YBCO film. The four symmetric peaks of the phi-scan indicate that the YBCO film is grown cube-on-cube epitaxially relationship to BHO. No additional texture components are observed in the superconducting layer grown on BHO/IBAD-MgO/Y2O3/Al2O3 buffered Hastelloy substrate. The in-plane FWHM for YBCO films is about 4.5°, much lower compared with the BHO buffer layers. The critical current density Jc of the YBCO coated conductor examined by inductive measurement technique at 77 K in self-field was about 0.7 MA/cm2, shown in Fig. 6, demonstrating the BHO a potential cap layer for superconducting coated conductor.

Conclusion

The BaHfO3 films deposited at different substrate temperature were prepared by reel-to-reel magnetron sputtering technique. A stress induced structure degeneration of BHO cap layer films is evidenced by Raman spectrum. The influence of temperature on the texture and surface morphology of BaHfO3 films were also investigated. BHO deposited at 850 °C has the relatively best texture. The in-plane and out-of-plane full width at half-maximum values of about 7.8° and 3.2°, respectively, and the BHO film has a dense, smooth, and crack-free morphology. Subsequently epi-growth of YBCO film on BHO cap layer has a pure c-axis orientation with a Jc about 0.7 MA/cm2 (77 K, self-field), which demonstrates BHO a new buffer layer for coated conductors.

References

Aytug T, Paranthaman M et al (2003) LaMnO3: a single oxide buffer layer for high-Jc YBa2Cu3O7−δ coated conductors. IEEE Trans Appl Supercond 13:2661–2664

Bhuiyan MS, Paranthaman M (2003) MOD approach for the growth of epitaxial CeO2 buffer layers on biaxially textured Ni–W substrates for YBCO coated conductors. Supercond Sci Technol 16:1305–1309

Erbe M, Hänisch J, Hühne R, Freudenberg T, Kirchner A, Molina-Luna L, Damm C, Van Tendeloo G, Kaskel S, Schultz L, Holzapfel B (2015) BaHfO3 artificial pinning centres in TFA-MOD-derived YBCO and GdBCO thin films. Supercond Sci Technol 28:114002

Goyal A, Norton DP, Budai JD, Paranthaman M, Specht ED, Kroeger DM, Christen DK, He Q, Saffian B, List FA, Lee DF, Martin PM, Klabunde CE, Hartfield E, Sikka VK (1996) High critical current density superconducting tapes by epitaxial deposition of YBa2Cu3Ox thick films on biaxially textured metals. Appl Phys Lett 69:1795

Hühne R, Subramanya Sarma V, Okai D, Thersleff T, Schultz L, Holzapfel B (2007) Preparation of coated conductor architectures on Ni composite tapes. Supercond Sci Technol 20:709

Iijima Y, Matsumoto K (2000) High-temperature-superconductor coated conductors: technical progress in Japan. Supercond Sci Technol 13:68

Karan NK, Katiyar RS, Maiti T, Guo R, Bhalla AS (2009) Raman spectral studies of Zr4+‐rich BaZrxTi1−xO3 (0.5 ≤ x ≤ 1.00) phase diagram. J Raman Spectrosc 40:370

Lu YM, Cai S, Liang Y, Bai CY, Liu ZY, Guo YQ, Cai CB (2015) The mechanism of the nano-CeO2 films deposition by electrochemistry method as coated conductor buffer layers. Physica C 512:1

Ma B, Koritala RE, Fisher BL, Uprety KK, Baurceanu R, Dorris SE, Miller DJ, Berghuis P, Gray KE, Balachandran U (2004) High critical current density of YBCO coated conductors fabricated by inclined substrate deposition. Phys C 403:183

Muroga T, Araki T, Niwa T, Iijima Y, Saito T, Hirabayashi I, Yamada Y, Shiohara Y (2003) CeO2 buffer layers deposited by pulsed laser deposition for TFA-MOD YBa2Cu3O7−x superconducting tape. IEEE Trans Appl Supercond 13:2532

Norton DP, Goyal A, Budai JD, Christen DK, Kroeger DM, Specht ED, He Q, Saffian B, Paranthaman M, Klabunde CE, Lee DF, Sales BC, List FA (1996) Epitaxial YBa2Cu3O7 on biaxially textured nickel (001): an approach to superconducting tapes with high critical current density. Science 274:755

Park CI, Condrate RA, Synder RL (1976) The Raman spectra of perovskite-structured alkaline earth hafnates. Appl Spectrosc 30:352

Sathyamurthy S, Salama K (2002) Processing aspects of MOD strontium titanate buffer layers for coated conductor applications. Phys C 377:208–216

Wang H, Foltyn SR, Arendt PN, Jia QX, MacManus-Driscoll JL, Stan L, Li Y (2004) Microstructure of SrTiO3 buffer layers and its effects on superconducting properties of YBa2Cu3O7−δ coated conductors. J Mater Res 19:1869

Xie L, Zhu J (2012) The electronic structures, born effective charges, and interatomic force constants in BaMO3 (M = Ti, Zr, Hf, Sn): a comparative first-principles study. J Am Ceram Soc 95:3597

Xiong J, Matias V, Wang H (2010) Much simplified ion-beam assisted deposition-TiN template for high-performance coated conductors. J Appl Phys 108:083903

Ying LL, Lu YM, Liu ZY, Fan F, Gao B, Cai CB, Thersleff T, Reich E, Huhne R, Holzapfel B (2009) Thickness effect of La2Zr2O7 single buffers on metallic substrates using pulsed laser deposition for YBa2Cu3O7−δ-coated conductors. Supercond Sci Technol 22:095005

Zhang JL, Evetts JE (1994) BaZrO3 and BaHfO3: preparation, properties and compatibility with YBa2Cu3O7−x. J Mater Sci 29:778–785

Authors’ contributions

XY, JZ and YL carried out the BHO films deposition and drafted the manuscript. FF and CB carried out the Raman analysis. ZL and YG worked on YBCO films deposition and its analysis. CC participated in its design and coordination. YL conceived of the study and finalized the manuscript. All authors read and approved the final manuscript.

Acknowledgements

This work is partly sponsored by Shanghai Key Laboratory of High Temperature Superconductors (14DZ2260770); the Science and Technology Commission of Shanghai Municipality (13111102300 and 14521102800), the National Natural Science Foundation of China (51572165, 11174193, 51371111 and 51202141).

Competing interests

The authors declare that they have no competing interests.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Zheng, J., Fan, F., Yan, X. et al. Epitaxial growth of BaHfO3 buffer layer and its structure degeneration analysed by Raman spectrum. SpringerPlus 5, 1908 (2016). https://doi.org/10.1186/s40064-016-3563-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40064-016-3563-9