Abstract

Annual ring width, warp, dynamic Young’s modulus, and static bending properties were evaluated for 2 × 4 lumber produced from Larix sibirica trees naturally grown in five different provenances of Mongolia. The lumber was also visually graded according to Japanese Agriculture Standard for structural lumber for wood frame construction. Mean values of dynamic Young’s modulus, modulus of elasticity, and modulus of rupture for lumber in each provenance ranged from 9.89 to 14.46 GPa, 7.53 to 13.02 GPa, and 33.0 to 68.7 MPa, respectively. Significant geographic differences were found in all examined properties of lumber among the five provenances. No significant relations were found between annual ring width and other properties, suggesting that radial growth rate of L. sibirica trees naturally grown does not always affect reduction on mechanical properties of lumber. Knots and wane were main factors downgrading lumber among the evaluated factors. Tree height, stem shape, and juvenile wood percentage of logs more affected lumber quality of L. sibirica trees from natural forests.

Similar content being viewed by others

Introduction

Larix species are known to have high growth rate at young age and good physical and mechanical properties of mature wood [1,2,3]. In addition to those characteristics, Larix wood shows good appearance and higher natural durability [4, 5]. By this nature, the wood of Larix species obtained from both natural stands and plantations is considered as valuable timber resources.

For effective wood utilization, it is important to understand variation of property and quality of woods. In Larix species, several researchers have been reported on geographic variations of growth characteristics and wood properties [2, 5,6,7,8]. For example, Takada et al. [6] evaluated the geographic variation of Young’s modulus of stem of Larix kaempferi in Japan. They found that, of three test stands, only one test site showed significant differences in Young’s modulus among provenances. Curnel et al. [5] also found among-provenance’s differences in wood decay resistance in Larix species. In Larix sibirica, Koizumi et al. [2] reported that wood density of this species significantly differed among five natural stands in South Central Siberia, Russia. These reports suggest that interactions between provenance and environment may affect wood quality in Larix species.

Mongolia also use wood of Larix, especially for L. sibirica, as structural lumber construction, since over 70% of the forest area in the country is covered with this species [9]. Even though L. sibirica wood is used for structural lumber, available information on wood properties was still limited in this species grown in Mongolia. Recently, several researchers have tried to clarify the wood properties and drying process of L. sibirica naturally grown in Mongolia [10,11,12]. Ishiguri et al. [10] investigated the basic density, shrinkage, bending properties, compressive strength parallel to grain, decay resistance, and amounts of chemical components of 200- to 240-year-old trees of L. sibirica grown in Mongolia. They found that values of modulus of elasticity (MOE), modulus of rupture (MOR), and compressive strength were lower near the pith, and increased to 4 cm from the pith, suggesting that juvenile wood affected the results. We also investigated geographical variation in growth characteristics, dynamic Young’s modulus of stem and logs, annual ring width, latewood percentage, and basic density of L. sibirica grown in five provenances of Mongolia [11]. The mean values of tree height, stress-wave velocity of stems, and all measured wood properties except for basic density were significantly different among the five provenances, although the stem diameter was almost the same among provenances. These results suggested that L. sibirica trees naturally grown in Mongolia have geographical variations in the mechanical properties in their wood. However, there is no information on lumber quality and its geographic variations of L. sibirica in Mongolia.

In the present study, to promote the lumber production under appropriate natural forest managements in Mongolia, 2 × 4 lumber was produced from L. sibirica logs collected from five different provenances where were famous L. sibirica forestry sites in Mongolia, and then lumber quality was evaluated. In addition, geographical variation of lumber quality was also discussed for efficient production of structural 2 × 4 lumber from L. sibirica trees naturally grown in Mongolia.

Materials and methods

Materials

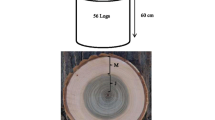

Five natural forests of L. sibirica were selected from five different provenances in Mongolia: Khentii, Arkhangai, Zavkhan, Khuvsgul and Selenge [11]. Geographic information and climatic conditions of the site are listed in Table 1. In addition, a total of 25 trees (five trees in each stand) with good stem shape without any severe damages were selected to cut. Before cutting trees, stress-wave velocity of stems was measured for these selected trees. After cutting trees, logs 2 m in length were obtained from 1.3 m above the ground until the top diameter of each log became less than 14 cm. A total of 111 logs were collected from the harvested 25 trees (from 3 to 6 logs from a tree) [11]. Dynamic Young’s modulus of all logs was measured by the tapping method [13]. Table 2 shows mean values of growth characteristics and stress-wave velocity of harvested trees, and dynamic Young’s modulus of logs. Although the stem diameter was almost the same in all provenances, the mean values of tree height and stress-wave velocity of stems, and dynamic Young’s modulus of logs were significantly different among the five provenances.

Taper and juvenile wood percentage of logs

The butt- and top-end diameters of each log were measured. Taper of log was calculated by the following equation [14]:

where d1 (cm) is the butt-end diameter of log, d2 (cm) is the top-end diameter of log, and L (m) is the length of the lumber.

Percentage of juvenile wood volume in a log was also estimated. In the previous paper [10], juvenile wood was thought to exist within 4 cm from pith in L. sibirica trees naturally grown in Mongolia. Juvenile wood percentage of logs was calculated as the proportion of volume of 4 cm from the pith in each log to total volume of a log calculated using mean values of butt and top diameter and length of log.

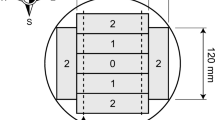

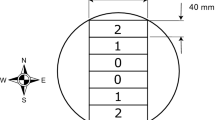

Lumber production

A total of 111 logs, 2 m in length, were used in the present study. The logs were sawn into lumber, as many as possible, with 100 × 50 mm cross section. A total of 190 pieces of lumber were obtained from the logs. The lumber was stacked by about 30 layers with wood stickers with 25 × 25 mm cross section at laboratory without air conditioner or heater in Ulaanbaatar, Mongolia. The lumber was air-dried from August 2017 to August 2018. Unfortunately, temperature and relative humidity were not recorded in the room during air-drying, but minimum, maximum, and mean monthly temperature and relative humidity of Ulaanbaatar, Mongolia, during air-drying were as follows: − 22.4 (January 2018), 17.9 (June 2018), and 2.0 °C, and 30 (May 2018), 71 (December 2017), and 58%. After air-drying, the lumber was planned into 89 × 38 mm cross section.

Lumber quality

Annual ring width, moisture content, deformation of lumber (bow, crook, and twist), dynamic Young’s modulus, and static bending properties were measured as lumber quality.

The bow and crook were determined as maximum deflection of lumber. Bow and crook of the lumber were calculated as the proportion at maximum deflection of bow and crook in each lumber length. To determine twist, lumber was set on a flat surface of a steel beam. After fixing three edges of a lumber, distance between remaining one edge and the flat surface was measured. Twist of the lumber was calculated as follows:

where h (mm) is the measuring distance and w (mm) width of the lumber.

After bending test, small-clear specimens (2.5 cm in thickness) were obtained from the lumber. The digital images (1200 dpi) of cross sections of the specimens were captured by a scanner and incorporated into a personal computer. The total number of annual rings on the cross section and total width of annual rings were measured by the image analysis software (ImageJ, National Institute of Health). Annual ring width of the lumber was determined by dividing total width by the total number of annual rings. In addition, the same specimens were also used to determine moisture content by oven-dry method.

Visual grading

All pieces of lumber were graded according to Japan Agriculture Standard for structural lumber for wood frame construction [15]. For grading, the typical visual sorting criteria, such as annual ring width, knots size, existence and size of holes, slope of grain, deformation (bow, crook, and twist), wane, and crack, were measured on surfaces of a lumber as described in Japan Agriculture Standard. Based on the measurements, the lumber was classified into the following grades: Selected, Nos. 1, 2, 3, and out grading according to Japanese Agriculture Standard for structural lumber for wood frame construction.

Dynamic Young’s modulus and static bending properties of lumber

Dynamic Young’s of modulus of lumber (DMOElum) was determined by tapping method [13]. To determine density at testing, weight, length and dimensions of lumber were measured by portable electric balance (SL-20K, A&D), laser measure (GLM-50C, Bosch), and digital calipers (CD-15CX, Mitutoyo), respectively. One cross end of each lumber was tapped by a small hammer, and then first resonance frequency of longitudinal vibration was obtained by a handheld fast Fourier transform (FFT) analyzer (AD-3527, A&D) with an accelerometer (PV-85, Rion) set on the other end of each lumber. DMOElum was calculated by the following equation:

where l (m) is the length of the lumber, f (Hz) is the first resonance frequency, and ρ (kg/m3) is the density of the lumber at testing.

After measuring dynamic Young’s modulus, four-point static bending test was conducted using a material testing machine (WDW-20E, Jinan Kason Testing Equipment). Load speed, support span, and distance between load points were 14 mm/min, 1602 mm, and 534 mm, respectively. The load was applied to edgewise direction. MOE and MOR of lumber were determined by the following equations:

where ΔP (N) is the difference of load between 10 and 40% values of maximum load (Pmax), Δy is the difference of deflection corresponding to ΔP, l (mm) is the span, \(l^{\prime}\) (mm) is the difference between load points, b (mm) is the width of specimen, and h (mm) is the height of specimen.

Data analysis

All data analyses were conducted using a software (Excel 2016, Microsoft). Mean values of each property were calculated by averaging values of individual trees within a provenance. An analysis of variance was applied to evaluate the differences in measured lumber properties among the provenances.

Results and discussion

Mean values of lumber properties

Mean values of the moisture content, annual ring width, air-dry density, and deformation of lumber are listed in Table 3. The mean values of annual ring width varied among five provenances. The highest and lowest mean values of annual ring width of 2 × 4 lumber were found in Arkhangai (3.4 mm) and Zavkhan (0.5 mm), respectively (Table 3). The mean values of air-dry density of lumber were 0.61, 0.63, 0.62, 0.55, and 0.59 g/cm3 for Khentii, Arkhangai, Zavkhan, Khuvsgul, and Selenge, respectively. Compared to air-dry density of 2 × 4 lumber produced from the trees in other Larix species, obtained mean values of air-dry density in the present study were relatively higher than those of L. kaempferi, Larix decidua, and Larix dahurica, but almost the same with Larix gmelinii (Table 4). Among the five provenances, mean values of bow, crook, and twist ranged from 0.05 to 0.17%, 0.03 to 0.07%, and 0.06° to 0.16°, respectively (Table 3). The lowest values of average bow (0.05%), crook (0.03%) and twist (0.06°) were found in Khentii. The highest mean values of bow (0.17%) and twist (0.16%) were found in Khuvsgul.

Mean values of dynamic Young’s modulus, MOE, and MOR of lumber ranged from 9.89 to 14.46 GPa, 7.53 to 13.02 GPa, and 33.0 to 68.7 MPa, respectively (Table 5). Bending properties of 2 × 4 lumber in Larix species have been reported by several researchers [1, 5, 16,17,18,19]. In L. kaempferi, as shown in Table 4, mean values of MOE and MOR were 8.44 GPa and 39.5 MPa for 2 × 4 lumber produced from 31-year-old trees planted in Canada [16], and 8.86 GPa and 32.9 MPa for 2 × 4 lumber produced from 63-year-old trees planted in Japan [17]. Chui and MacKinnon-Peters [16] also measured MOE and MOR of 2 × 4 lumber of L. decidua, and they were 10.93 GPa and 43.8 MPa for 63-year-old trees planted in United States of America, and 8.98 GPa and 40.5 MPa for 34-year-old trees planted in Canada, respectively (Table 4). In addition, Ethington et al. [1] reported that MOE and MOR of 2 × 4 lumber of L. dahurica ranged from 11.10 to 14.06 GPa (1.610 to 2.039 × 106 psi), 45.3 to 67.4 MPa (6.564 to 9.779 psi), respectively (Table 4). The mean values of MOE and MOR were similar or relatively higher than those of other Larix species (Table 4).

Figures 1 and 2 show longitudinal variations of MOE and MOR of lumber in each provenance. Except for Khuvsgul, MOE of lumber slightly decreased from bottom to top of trees. In Khuvsgul, it slightly decreased with increase of height positions and then increased at most upper position (Fig. 1). The similar trends were also observed in dynamic Young’s modulus of logs used in the present study [11]. On the other hand, longitudinal patterns of MOR of lumber varied not only among the provenances, but also within a tree (Fig. 2).

Correlation coefficients between dynamic Young’s modulus of lumber and MOE or MOR of lumber are listed in Table 6. Dynamic Young’s modulus of lumber was strongly correlated with the both MOE and MOR of lumber, except for Khuvsgul, suggesting that measuring the dynamic Young’s modulus of lumber is a useful indicator for predicting bending properties of L. sibirica lumber.

Relationships between annual ring width and mechanical properties

Miyajima [20] investigated the relationships between the annual ring width and the mechanical properties of 2 × 4 lumber of L. kaempferi trees planted in Japan. He reported that increasing annual ring width resulted in the decreasing values of the MOE and MOR. To clarify similar tendency with Miyajima [20], the relationships between annual ring width and lumber properties were analyzed in the present study (Table 7). No significant relations were found between annual ring width and lumber properties, except for the lumber from Khentii. Negative significant correlations were recognized between annual ring width and air-dry density, dynamic Young’s modulus, or MOE in the lumber from Khentii. Our results in L. sibirica except for the lumber from Khentii were not the same with those reported by Miyajima [20] in L. kaempferi. Therefore, it is considered that radial growth rate of trees does not always relate to lumber quality in L. sibirica.

For the determination of lumber quality, effect the presence of juvenile wood on lumber quality should be considered. Ishiguri et al. [10] showed that wood with lower MOE and MOR, like juvenile wood, was present within 4 cm from the pith for L. sibirica naturally grown in Mongolia. In the present study, juvenile wood percentage in logs was calculated. As a result, juvenile wood percentage gradually increased from bottom to top in all provenances (Fig. 3). The longitudinal trend in juvenile wood percentage was similar to that in MOE of lumber (Fig. 1). Thus, juvenile wood of this species is considered as one of the primary factors to reduce lumber quality. If the wood with wider annual rings was found around the pith area, negative correlations will be found between annual ring width and strength properties. Further research is needed to clarify the relationships between annual ring width and formation of juvenile wood in this species.

Geographical variation of lumber properties

It is known that geographical variations are found in growth characteristics and wood properties in Larix species [2, 6, 11]. In L. kaempferi, Takada et al. [6] investigated geographic variations of Young’s modulus of stems for L. kaempferi trees originated from 19 different seed provenances in two provenance-trial test stands in Hokkaido, Japan. As the results, they found that some better or worse provenances in Young’s modulus rankings were common in two test stands, although there were no correlations between the test stands. Koizumi et al. [2] examined geographical variations of anatomical and mechanical properties of wood in L. sibirica grown in five natural stands of Russia. They found that the wood from Baikal site had very high density, especially due to the narrow growth rings, whereas the wood from the Altai site in the mountain range had a low density. In addition, we previously reported that geographical variations were found tree height, stress-wave velocity, latewood percentage, and dynamic Young’s modulus of logs in L. sibirica naturally grown in Mongolia [11]. In the present study, all lumber properties showed significant differences among the provenances (Tables 3 and 5). The results suggest that wood of L. sibirica trees naturally grown in Mongolia has geographic variation in lumber quality as well as growth characteristics and wood properties.

Figure 4 shows the results of visual grading for lumber from each provenance. Percentage of number of lumber assigned to the Selected and No. 1 in each stand showed more than 50% in all stands except for Arkhangai. In contrast, 50% of total lumber showed outgrading in Arkhangai (Fig. 4). Main reasons of downgrading lumber from Arkhangai were knot and wane (Table 8). Among the provenances, the highest taper value of log was found in Arkhangai (Table 9); although the trees from Arkhangai used in the present study showed almost the same diameter as those other provenances at 1.3 m above the ground, tree height was quite lower than other provenances (Table 2). In addition, juvenile wood percentage of logs at 5.3–7.3 m showed the highest values in Arkhangai (Fig. 3). Based on the results, tree height, taper value and juvenile wood percentage of logs are considered to affect lumber quality considerably in L. sibirica trees naturally growing in Mongolia.

Conclusions

Geographical variations of 2 × 4 lumber quality were examined in L. sibirica trees naturally grown in Mongolia. Among five provenances, significant differences were found in all lumber properties such as air-dry density, deformation, dynamic Young’s modulus, MOE and MOR. Radial growth rate of L. sibirica trees naturally grown did not affect decrease in mechanical properties of lumber. Knot and wane were main factors for downgrading lumber among the evaluated factors. Tree height, stem shape, and juvenile wood percentage of logs are considered to affect lumber quality considerably of L. sibirica trees from natural forests in Mongolia.

Availability of data and materials

Not applicable.

Abbreviations

- MOE:

-

modulus of elasticity

- MOR:

-

modulus of rupture

References

Ethington LR, Gupta R, Green WD (1997) Visual stress grades of Dahurian larch lumber. For Prod J 47(1):82–88

Koizumi A, Takata K, Yamashita K, Nakada R (2003) Anatomical characteristics and mechanical properties of Larix sibirica grown in south-central Siberia. IAWA J 24:355–370

Zhong Y, Ren H (2014) Reliability analysis for the bending strength of larch 2 × 4 lumber. BioResources 9:6914–6923

Gierlinger N, Jacques D, Schwanninger M, Wimmer R, Pâques LE (2004) Heartwood extractives and lignin content of different larch species (Larix sp.) and relationship to brown-rot decay-resistance. Trees 18:230–236

Curnel Y, Jacques D, Gierlinger N, Pâques LE (2008) Variation in the decay resistance of larch to fungi. Ann For Sci 65:810–818

Takada K, Koizumi A, Ueda K (1992) Geographic variation in the moduli of elasticity of tree trunks among Japanese larch in provenance trial-stands. Mokuzai Gakkaishi 38:222–227 (In Japanese with English summary)

Karlman L, Martinsson O, Karlsson C, Skaaret G (2013) Yield of Larix sukaczewii Dyl. and larch hybrid in northern Scandinavia. Eurasian J For Res 16(1):45–56

Cáceres CB, Hernández RE, Fortin Y (2018) Variation in selected mechanical properties of Japanese larch (Larix kaempferi, [Lamb.] Carr.) progenies/provenances trials in Eastern Canada. Eur J Wood Wood Prod 76:1121–1128

Dulamsuren C, Hauck M, Khishigjargal M, Leuschner HH, Leuschner C (2010) Diverging climate trends in Mongolian taiga forest influence growth and regeneration of Larix sibirica. Oecologia 163:1091–1102

Ishiguri F, Tumenjargal B, Baasan B, Jigjjiv A, Pertiwi YAB, Aiso-Sanada H, Takashima Y, Taiichi Iki, Oshima J, Iizuka K, Yokota S (2018) Wood properties of Larix sibirica naturally grown in Tosontsengel, Mongolia. Int Wood Prod J 9(3):127–133

Tumenjargal B, Ishiguri F, Aiso-Sanada H, Takahashi Y, Baasan B, Chultem G, Ohshima J, Yokota S (2018) Geographic variation of wood properties of Larix sibirica naturally grown in Mongolia. Silva Fenn 52: no 4, article id 10002

Ayush T, Jigjjav A, Baasan B, Pertiwi YAB, Ishiguri F, Yokota S (2019) Drying performance of a direct-fired kiln developed in Mongolia. Wood Res 64(1):177–184

Sobue N (1986) Measurement of Young’s modulus by the transient longitudinal vibration of wooden beams using a fast Fourier transformation spectrum analyzer. Mokuzai Gakkaishi 32:744–747

Butler MA, Dahlen J, Eberhardt TL, Montes C, Antony F, Daniels RF (2017) Acoustic evaluation of loblolly pine tree- and lumber-length logs allows for segregation of lumber modulus of elasticity, not for modulus of rupture. Ann For Sci 74:20–35

MAFF (2018) www.maff.go.jp/j/kokuji_tuti/kokuji/pdf/k0001410.pdf. Accessed 6 Aug 2018

Chui YH, MacKinnon-Peters G (1995) Wood properties of exotic larch grown in eastern Canada and north-eastern United States. Forest Chron 71:639–645

Nagao H, Washino K, Kato H, Tanaka T (2003) Estimation of timber strength based on the distribution of MOE in the stem, Application to Japanese larch. Mokuzai Gakkaishi 49:59–67 (in Japanese with English summary)

Ishiguri F, Matsui R, Iizuka K, Yokota S, Yoshizawa N (2008) Prediction of the mechanical properties of lumber by stress-wave velocity and Pilodyn penetration of 36-year-old Japanese larch trees. Holz Roh Werkstoff 66:275–280

Zhou H, Han L, Ren H, Ju J (2015) Size effect on strength properties of Chinese larch dimension lumber. BioResources 10:3790–3797

Miyajima H (1985) Basic wood quality of plantation-grown larch, Todo-Fir and Korean pine in the Tomakomai experiment forest. Res Bull Coll Expt For Hokkaido Univ 42:1089–1115 (in Japanese with English summary)

Acknowledgements

The authors thank Ms. Yui Kobayashi and Mr. Tappei Takashima, students, Utsunomiya University, and Mr. Sarkhad Murzabek and Ms. Togtokhbayar Erdene-Ochir, Mongolian University of Science and Technology, for their assistance in measuring lumber properties.

Funding

A part of this research was supported by the M-JEED program of the Ministry of Education, Culture, Science, and Sports, Mongolia.

Author information

Authors and Affiliations

Contributions

BT contributed to experiments, data analysis and writing the manuscript. FI designed this study and also contributed to experiments, data analysis and writing the manuscript. HA-S contributed to experiments and discussion on the obtained results. YT and IN contributed to experiments and data analysis. BB and GC contributed to experiments. JO and SY contributed to discussion on the obtained results. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

This article is published under an open access license. Please check the 'Copyright Information' section either on this page or in the PDF for details of this license and what re-use is permitted. If your intended use exceeds what is permitted by the license or if you are unable to locate the licence and re-use information, please contact the Rights and Permissions team.

About this article

Cite this article

Tumenjargal, B., Ishiguri, F., Aiso-Sanada, H. et al. Geographical variations of lumber quality of Larix sibirica naturally grown in five different provenances of Mongolia. J Wood Sci 65, 43 (2019). https://doi.org/10.1186/s10086-019-1823-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s10086-019-1823-3