Abstract

A product/service system (PSS) facilitates remanufacturing and thus is the article’s subject. This article presents a first quantitative analysis, through a descriptive study, of the details of a PSS design case. To do so, an example of PSS design was conducted using a real offering in the marketplace, and this design episode was analyzed through protocol analysis developed further by the authors. The results of the analysis include reasonable hypotheses: PSS design begins with needs by and value for a customer, addresses primarily life cycle activities for solutions, and ends back with value. In addition, life cycle activities, which accounted for about 30% of the episode, were found to be given a central role within PSS design. Furthermore, reasoning about problems, which spent more than 30% of the design, seems to be a new and important type of activity in PSS design as compared to physical product design. This article contributes to greater understanding of PSS design process in quantitative terms and thus to developing effective support for PSS design. Knowledge about PSS enables the understanding of remanufacturing with a more holistic perspective and thus creating an opportunity for better optimization of remanufacturers’ activities.

Similar content being viewed by others

Background

Remanufacturing is the process of bringing used products to a ‘like-new’ functional state by rebuilding and replacing their component parts [1]; as several articles [2–5] point out, it goes hand-in-hand with the product/service system (PSS). PSS, an emerging marketing concept where an original equipment manufacturer (OEM) will sometimes retain ownership of a physical product, can be defined as ‘tangible products and intangible services designed and combined so that they jointly are capable of fulfilling specific customer needs’ [6]. Neither remanufacturing nor PSS is an aim of a business. However, PSS is indeed a potential means in an ever-increasing part of the industry. With PSS, an OEM can have better control in taking back used products and in maintaining better product condition, and thus PSS facilitates remanufacturing. Therefore, this article addresses PSS - with a more holistic approach than remanufacturing - while observing its contribution to remanufacturing.

Design is important in PSS as it has a high impact on quality. However, sufficient insights into PSS design are not available (see e.g., [7, 8]). The literature discussing design for remanufacturing, including design of product, service, and supporting system, has the same tendency [9] - the overall volume on the subject is low. Within PSS design literature, understanding of PSS design processes is scarce. In fact, very little research has been carried out on how PSS is actually designed. The processes of PSS design are not sufficiently understood in detail from a scientific standpoint. One cannot, for example, answer what is happening inside the PSS design processes along time; this question has been posed and answered many times, however, in design research in general (e.g., [10]). Better information grounded on design as a time-based activity can be used to develop richer models of design [11]. Were this information available in PSS design, it could be effectively used to develop PSS design support methods and tools.

Motivated by this gap, this paper aims to propose a method to analyze PSS design cases, analyze the details of the entire process of a PSS design case using the proposed method, and thus contribute to the understanding of PSS design processes. To do so, protocol analysis was used as a basis for the method, and an instance of PSS design was conducted to improve a PSS offering in the marketplace. The PSS design was carried out by three people working as a group. Then, this design episode was analyzed to capture some salient characteristics of PSS design. This article is extended based on previous work [12].

The remainder of the paper is structured as follows: Section Remanufacturing and PSS clarifies the relation between remanufacturing and PSS, Section Literature review presents our research motivation, Section Research method describes the proposed and adopted method, Section Results - analysis of a PSS design episode shows the results of the analysis, Section Discussion discusses the results, and Section Conclusion concludes the paper.

Remanufacturing and PSS

The relation between remanufacturing and PSS is not clearly explained in the literature (one early paper [13] analyzed that between remanufacturing and service selling). PSS is often seen as a concept that does not specify types of included services, while remanufacturing needs specific service such as take back. Thus, remanufacturing can be seen as a concrete activity in PSS as already implied by various authors [2–5].

Setting the target of the research on PSS, i.e., at a more abstract level than remanufacturing itself, might be inefficient with the final aim of supporting and spreading remanufacturing in a wider range of industry. However, the fact that some features of PSS (e.g., strong relationship between a provider and a user) facilitate remanufacturing [2] makes this research approach beneficial.

Another benefit of this approach lies in the holistic and interdisciplinary nature of PSS. Researching PSS enables the understanding of remanufacturing with a more holistic perspective than researching remanufacturing alone and thus provides an opportunity to better optimize a company’s activities.

Furthermore, there are many more firms interested in PSS than only in remanufacturing. In fact, numerous manufacturers’ offerings today include services - in the USA and Finland, this combination of offerings exceeds 50% of all manufacturers [14]. This proportion can be a good target as a channel for disseminating PSS, and through this, dissemination remanufacturing can be promoted. Thus, promoting remanufacturing as a concrete type of PSS may be a good alternative to disseminating remanufacturing. The above provides justification for setting the research target on PSS in order to develop and disseminate knowledge about remanufacturing into industry.

Literature review

Need of descriptive quantitative study in PSS design research

Knowledge is needed about the thoughts and actions of designers throughout the process of designing in various contexts to create methods, if one assumes that designing is a procedure that can be taught and learned [15]. In order to develop knowledge, and thus methods and tools thoroughly in the engineering design discipline, a seminal work in this area by Blessing and Chakrabarti [16] recommends, in the following order: (1) descriptive study (DS-I) to characterize the concerned design process and derive, e.g., a reference model for developing a design method, (2) prescriptive study to produce, e.g., a normative design method, and (3) descriptive study (DS-II) to observe the design process by applying the developed normative method. A descriptive study (both DS-I and DS-II) aims at understanding the phenomenon of design and is argued to be a crucial part of design research together with a prescriptive study [16, 17].

Several PSS design methods have been proposed. Many of them (e.g., [18–20]) have been developed for PSS based on theories and methodologies for conventional product design (e.g., [21]) and extended through logical reasoning of what extension and modification is needed for integrating services with products. These methods, however, have the risk of mismatching how PSS design is actually conducted. On the other hand, little literature on PSS design methods has come out explicitly from the first type of descriptive study (DS-I) of an actual PSS design process. Two articles [22, 23] presenting the PSS design process with a more descriptive style are found. The process by Morelli [22], based on a case of telecom center design, consists of the following, and in this order: value proposition, market analysis, product/service definition, use-case analysis, tentative architecture, test, and final definition. Another process by Alonso-Rasgado and Thompson [23] produces the following information, also in order: (1) business ambitions of the client, (2) potential business solutions, (3) core definition of PSS plus PSS options, (4) enhanced definition of the potential PSS, and (5) risk analysis and evaluation of business cases. However, the information about these processes is only qualitatively written, and insights about quantitative details of PSS design processes are rarely available. In general, quantitative data about a given process serves as a fundamental way to improve a process, and thus, quantitative analysis is powerful in providing exact information. For instance, identifying the most time-consuming part of a process enables putting focus on that part to improve the efficiency of the whole process.

The lack of this understanding can be a problem for the research area - producing a number of methods and tools to support PSS design without understanding the PSS design processes thoroughly. This lack of understanding does not secure the optimum effectiveness of the developed normative design support methods, as well as the efficiency of improvement of the design process. Thus, descriptive and quantitative study would be among the most promising research streams to be further explored. This gap provides motivation for the authors to conduct research in order to understand more about PSS design processes in detail through a descriptive and quantitative study.

What to understand in PSS design

Following the demanded research stream identified in Section Need of descriptive quantitative study in PSS design research, the next question to be answered is what should be understood in PSS design; this section answers this question. According to Blessing et al. [24], ‘the aim of engineering design is to support industry by developing knowledge, methods and tools which can improve the chances of producing a successful product’. Among other things, this article focuses on methods to support industry with developing an effective PSS.

In general, to develop prescriptive methods, ‘it is important to understand the interdependencies in the design process and the activities during the process’ [15]. This article focuses on ‘the activities during the process’ as a first step. At present, for instance, almost none of the PSS design or design for remanufacturing literature can answer the following questions. These types of questions usually can be answered in general engineering design (referring to, e.g., a typology of design models [25]):

-

What concepts are the most time-consuming in the PSS design process?

-

Is there any difference regarding types of activities between different PSS design stages?

-

Does the entire PSS design process follow the waterfall model (see, e.g., [26])?

Even from the practical viewpoint, these questions are all relevant. Challenges for conventional manufacturing firms to develop PSS include establishing an effective development routine [27]. It is difficult to establish and rely on such a routine without knowing the answers to the questions above. What is missing is a fundamental understanding of the PSS design process, including concepts addressed and elemental processes taking place in the design process. For instance, if PSS design concentrates on discussing a limited set of concepts, developing support for addressing those concepts in detail would be effective; if discussion is spread between many types of concepts, however, addressing the relations between concepts would be important. In addition, dominant types of processes in PSS design would also suggest effective support - a process of creating a solution and analyzing an object can be supported effectively by creativity support software (TRIZ [28] is an example of software of this type in product design) and computer aided engineering (CAE)-like software, respectively. Thus, this article aims to answer, with regard to effective PSS design, the following:

-

(a)

Which concepts are frequently used in different stages?

-

(b)

Which elemental processes take place in different stages?

-

(c)

Which combination of concepts and processes are used?

Research method

Protocol analysis in general

This research adopts protocol analysis in order to quantitatively describe, structure, and analyze the process of a PSS design episode. Development of protocol analysis to analyze a process of technical problem solving is largely owed to Gero’s and Cross’ groups [11, 29]. Protocol analysis is based on the ‘think aloud’ method introduced by Ericsson and Simon [30] and further developed by van Someren et al. [31].

Protocol analysis facilitates detailed inspection of all the protocol data in a given process that has rich information regarding what is happening in a process. Unlike conventional content analysis methods, it focuses on understanding the cognitive process of a person or team of people conducting a task and thus is more suitable for the purpose of this research. This accords with the view of Carley [32], who points out that content-analytic procedures are appropriate and work well at macrolevels where the interest is in broad cultural concepts, but seems less effective at the microlevel, where psychological or cognitive phenomena need to be examined. Protocol analysis is used for different activities like teamwork [33] and in various fields such as psychology [34] and software engineering [35]. It is an established method in the discipline of design (as shown by, e.g., [11, 29]). In general, it is conducted in the following order [11, 30]: (1) setting the design task, (2) carrying out and recording the design, (3) transcribing the design episode, (4) segmenting (dividing the protocol into utterances) and encoding the utterances, and (5) analyzing the data.

The categories in the coding scheme adopted by each author vary depending on their interest. For instance, the categories used in architectural design [36] are for cognitive actions: physical (e.g., move a pen), perceptual (e.g., attend to shapes), functional, and conceptual. Another example [11] uses three columns for an episode of physical product design: the first column is from the viewpoint of the design object and coded by ‘Function’, ‘Behavior’, and ‘Structure’ as well as by different levels of abstraction. The second and the third are micro- and macrostrategies, respectively. The microstrategy categories are ‘Proposing Solution’, ‘Analyzing Solution’, and ‘Explicit Strategies’, while the macrostrategy categories are ‘Top-Down’, ‘Bottom-Up’, ‘Decomposing the Problem’, ‘Backtracking’, and ‘Opportunistic’. The term ‘strategies’ can be understood as an indication of the effectiveness of characterizing each process in light of how the goal is approached, as design is a goal-oriented activity. The microstrategies are effective in characterizing elemental processes, while the macrostrategies are useful to link to design models (e.g., [25]).

Protocol analysis in any coding scheme can derive extremely rich, quantitative, and objective information, such as utilized concepts and elemental processes across the temporal dimension, because it can follow a certain predefined framework that captures how a designer confronts and handles a problem [11]. Therefore, it is a powerful and suitable tool for the purpose of this research. This feature cannot be obtained by other methods; for instance, a retrospective interview study of a design case - one of the major methods - is here obviously impossible to produce information with the same characteristics.

However, an attempt to apply protocol analysis to PSS design is scarcely found in the literature. In some existing research of physical product design [11], ‘Function’, ‘Behavior’, and ‘Structure’ were adopted to code an aspect of the problems addressed in the protocol, which can be interpreted as identification of concepts of a design object. How to represent a design object is an issue to apply protocol analysis in this research because a design object in PSS design is different from the physical product design [37]. The solution adopted in this research is described in the next section.

Design parameters in PSS

The question is which set of parameters to represent a design object in the case of PSS design is necessary and sufficient. Although the PSS research community does not seem to agree on it, consolidating various PSS concepts based on the PSS Layer Method [38] can be used as a working solution. This research employs the nine dimensions of this method.

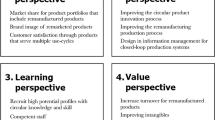

This method adopts the nine dimensions by reflecting divergent viewpoints of different actors involved in PSS, as well as various aspects not only concerning the physical product but also the business model as well. The nine dimensions consist of the following. ‘Needs’ (dimension 1) are satisfied by ‘Customer Value’ (dimension 2), which a customer perceives. ‘Needs’ involves capturing non-solution-oriented needs, e.g., the need for access to broadcast information. ‘Customer Value’ is the benefit obtained through the PSS and can be classified into four types of benefits: economic, environmental, social, and technical. Such value has to be created by ‘Deliverables’ (dimension 3), which have value for the customer. The deliverables are a result (either material or immaterial) of delivery processes, i.e., ‘Life cycle Activities’ (dimension 4). ‘Life cycle Activities’ are performed by the PSS provider and/or the customer, e.g., take back and reconditioning. To implement a life cycle activity chain, resources are needed. Actors (dimension 5), Core Products (dimension 6) (what is called core in remanufacturing), and Periphery (like IT infrastructure or public transport systems) (dimension 7) are such resources. Actors can include the provider, the user, and the logistics company. ‘Contract Elements’ (dimension 8) frame the entire value creation process, including ‘Finance’ (dimension 9) (especially about the payment model, e.g., flat rates, pre-paid, scheduled, or incremental (down-) payment), offerings, and finally the entire business model. This covers most of the important elements of PSS with multi-disciplinary characteristics and is at least a workable solution.

Method proposed and adopted in this research

This section describes the method proposed and adopted in this research based on work by Gero et al. [11] and Müller [38]. The reason for adopting the work by Gero et al. [11] is its generic characteristics and its modularity realized by the three columns (one column concerns a design object and can be replaced with another for PSS). This research intends to capture general trends of PSS design because few research results have been presented in the area and because it coincides with the based method [11].

The coding scheme is adjusted from research by Gero et al. [11] using ‘Function’, ‘Behavior’, and ‘Structure’ (in the case of product design) for the column concerning a design object; the nine dimensions of the PSS Layer Method [38] (as shown in Table 1 with abbreviations used in the paper) are adopted to describe the object (PSS in this case) as explained in the previous section. Thus, the nine dimensions are substituted to the set of ‘Function’, ‘Behavior’, and ‘Structure’, which were used for the design object column [11].

To be able to answer questions b and c, categories for the process characteristics were prepared. The same macrostrategies were used as in the existing cases [11] (see Table 2) to characterize the underlining trends of the utterances. Note that ‘Top-Down’ is interpreted in the PSS design context as a process of elaborating need/value and identifying product/service (‘Bottom-Up’ is for reasoning in the opposite direction).

To complement the macrostrategies, the microstrategies shown in Table 3 are used. This contributes to characterize the motivations of the utterances. The microstrategies were created after modification of the existing cases [11], where ‘Proposing Solution’, ‘Analyzing Solution’, and ‘Explicit Strategies’ were the three categories. Now, ‘Introducing Problem’, ‘Analyzing Problem’, ‘General Strategies’, and ‘Discussion Strategies’ are newly introduced groups of categories. There are two reasons for this addition. First, the PSS design process is argued to be a zigzag process between the problem space and the solution space (e.g., [22]), while a traditional product design process focuses more on exploration in the solution space. Therefore, ‘Introducing Problem’ and ‘Analyzing Problem’ were two groups of categories foreseen to be useful to include. Second, the analysis of PSS design is conducted by multiple people, as opposed to the cases [11], and thus, it is more likely to have sentences questioning or agreeing with other people in the design episode. Thus, two additional groups of categories, ‘General Strategies’ and ‘Discussion Strategies’, were added.

In sum, encoding each segment of the design episode is done from three aspects, i.e., the PSS dimension, the macrostrategy, and the microstrategy. The alternatives are shown in Tables 1, 2, and 3. Note that an alternative, ‘no dimension applied’, was possible to be chosen for the PSS dimension.

The encoding is first performed independently by two people; this can be seen as the first phase of the Delphi method [39]. Then, after a 3-day break at a minimum, the same two people check coding consistency by comparing the two different protocols. The two encoders reach the final, agreed coding through discussion to derive the final protocol. This aims to increase the robustness of the final protocol. This arbitration step corresponds to the latter phases of the Delphi method.

How the PSS design was carried out

Addressed PSS offering and business

The company studied develops, manufactures, and delivers drilling equipment for the construction industry. The construction industry can be characterized by its huge project budgets and less than precise predictions for operations due to the variable conditions (at least compared to production in a factory). These uncertain conditions make operators’ skills (such as digging a hole through rocks/soils with different characteristics within a given time) important. Construction is also typically carried out under great time pressure, and given that work is often performed in remote locations, machine availability is in high demand.

Training, spare parts delivery, and maintenance, repair and overhaul (MRO) are part of the company’s service portfolio. An offering for the construction business, based on a complex machine such as drilling equipment and its related services, has good potential for being designed and offered as a PSS. Another firm in the construction business also offers a PSS by integrating construction machines and services such as monitoring, repair, and performance reports [40]. This is technically realized by the firm’s information and communication network with individual machines, which the studied company has not yet installed.

The motivation for this company to provide PSS is to create higher value for its customers/users. The PSS offering investigated was one of the major services provided by the company. Instead of selling a physical product alone, i.e., a drilling machine, the company also delivers warranty of quality, original spare parts on time, early information on the next MRO activity, grease and oil of adequate quality, cleaning equipment, and a service binder. Life cycle activities are early fault detection, MRO prognostics, and execution including scheduling, transport of spares to the field, and take back of rotatable and broken parts.

The design task and preconditions of designers

The task of this design was to find several rational improvement options for this offering and represent them with the nine parameters within approximately 1 h. This task was given to a group of three designers working in a collaborative manner. The reason to not give the task to a single designer was the intention to obtain more ideas from a broader range, which appears to be the rationale in PSS design addressing various dimensions. In addition, the reason why the frame for description, i.e., the nine parameters, was used is that it is difficult to understand how to describe the output without a given frame.

Three designers were nominated from master’s students majoring in mechanical engineering at Kyoto University, Japan. Each had basic knowledge of industrial economics in addition to knowledge in mechanical engineering. None of them were instructed to play a certain function, and the three designers had a homogeneous role in the task. As Stempfle and Badke-Schaub [41] point out, although generalizations from student teams to design teams in industry must be drawn with caution, some insight is expected to be gained into basic thinking processes which are not contaminated by unknown and unpredictable factors which occur in a field setting. This point is revisited in Section Factors influencing PSS design.

Preparation for the design

Before conducting the design, the designers accomplished the following, in this order:

-

1.

Understand the background for industrial interest in PSS.

-

2.

Understand the PSS Layer Method.

-

3.

Understand the addressed offering through studying materials (brochures, etc.) from the company and by visiting a tunnel construction site, located in Kumano, Japan, where similar services and the same core product of the PSS offering were provided by the company.

-

4.

Create, working individually, one or two improvement ideas based on the current offering described in the PSS Layer Method by a developer and an expert in the method.

-

5.

Review feedback about the description from the PSS Layer Method expert in order to correct misunderstandings and to stimulate ideas.

-

6.

Understand how the design should be conducted, e.g., by thinking aloud.

Each designer spent around 14 h on the activities above, excluding the visit to the site. Note that the designers were not allowed to exchange information about the design with the others in order to prevent any co-development in advance of the design session. It should also be noted that the designers did not learn any particular methods for PSS design in order to avoid influencing the design process.

Design environments

The design episode was created in the form of group discussion in the Japanese language, the mother tongue of the three designers. The execution of the design took place in October 2010. A poster-sized paper was used to describe information via post-its for the nine dimensions. In addition, a whiteboard and pens were used for complementary means (see Figure 1). Besides the three designers, two other people were present during the design. One of them, who had more information about the offering and the company, assisted the designers with the aim of ensuring that everything went according to plan. This person also worked as a consultant with external sources during the design. This person, as well as the other attendant, transcribed and encoded the protocols in order to get the best possible insight into the design activities. The equipment used for both audio and video recording consisted of two video cameras with mobile microphones to provide the best possible sound recording.

Outcome of the PSS design - generated ideas for improvement

The design episode lasted for 1 h, 13 min, and 29 s. A number of distinguishable ideas for improving the offering were generated during the design and are presented below. These are all effective solutions with respect to the information given to the designers, some of which is described in Section Addressed PSS offering and business (note that the case by another firm [40] was not discussed in advance to avoid any copying of ideas). Thus, the given design episode can be regarded as one of effective design.

-

1.

Have an on-site service technician for enabling quicker service and sharing more information on machine operation.

-

2.

Provide more information about the provider’s costs with a customer for more transparency of the cost structure.

-

3.

Estimate economic costs of services, particularly for a concerned customer.

-

4.

Introduce an IT system for the different actors to share the current status of a machine and their needs.

-

5.

Introduce a kaizen system at the site to facilitate more efficient machine operation.

-

6.

Improve safety for machine operators (usually not from the PSS provider).

-

7.

Introduce qualification skills for machine operators to assure proper operation of equipment.

-

8.

Make the charging scheme for services easier for a customer to project their economic costs.

-

9.

Support the customer’s corporate social responsibility (CSR) activities at the construction site.

Results - analysis of a PSS design episode

Encoding

The design episode was transcribed into 1,450 segments. The transcripts were the main source for the segmented texts, but when ambiguity about the texts appeared, the video of the design episode as well as the designers were consulted. A table shows an example of a part of the segmented protocols with coding (see Appendix).

The results are shown in Table 4, where the first column shows agreement between two encoders. The second and the third columns show agreement within encoder A and encoder B, respectively. For example, in categorizing the PSS dimensions, two encoders agreed with 67% of their first codings, while the first coding by encoder A was different from the final one by 8%. The ratio of agreement between the encoders in the microstrategies was the lowest, 36%.

Overall trend along the timeline

Figure 2 shows the transitions of dialogues of the entire PSS design along the timeline in terms of microstrategies, macrostrategies, and PSS dimensions (from the top). Note that microstrategies are categorized into a higher level and limited to the four groups (by removing those concerning strategies).

Figure 2 shows, for instance, that the PSS dimensions begin with the customer view (i.e., ‘Needs’ and ‘Customer Value’) and take a descent through the dimensions to return to the customer view later. After around 27 min, the graph for the PSS dimensions shows a focus change from the customer view to the ‘Life cycle Activity’ and then to other dimensions. Note that discontinuous parts of each graph mean no appropriate category is assigned to the corresponding segment.

Analysis by divided parts

To make a trend easier to understand and to answer to questions a, b, and c, the design episode has been divided into five parts, evenly distributed in terms of number of utterances. The reason for adopting the number of utterances is its convenience to test the data statistically. Tables 5, 6, and 7 show numbers of utterances of each micro/macrostrategy used and those of each PSS dimension discussed, respectively. All the numbers in these tables are a percentage of the whole PSS design; 100, for instance, means 100% and corresponds to 1,450 utterances.

In order to check if there is a significant difference in the data in Tables 5, 6, and 7, the utterance numbers (i.e., matrixes with the elements on Tables 5, 6, and 7 multiplied by 1,450 and divided by 100) were tested statistically. As a result, the null hypothesis of independence between the row and column variables is rejected by the Chi-square test with a p value less than 0.01 for all the data sets. This means that the distributions of micro- and macrostrategies used and that of PSS dimensions discussed depend on the parts; that is, they vary along time.

The numbers above the average are shown in italics in the table to visualize the difference. Table 5 shows that two microstrategies, ‘Introducing Problem’ (I) and ‘Analyzing Problem’ (Z), are used in earlier parts, while the strategy ‘Analyzing Solution’ (A) is used later. Actually, ‘Introducing Problem’ (I) and ‘Analyzing Problem’ (Z) accounted for 49% within parts 1 and 2. Table 6 shows a clear shift of the macrostrategies used in parts 1/2 and parts 3/4/5, from ‘Top-Down’ (TD) to ‘Bottom-Up’ (BU).

Table 7 shows that the customer view, i.e., ‘Need and Customer Value’, are discussed 14% (8% and 5% each) in part 1 and 12% in part 2. Actually, 64% of the utterances in part 1 and part 2 were spent in these two dimensions. In part 3 and part 4, the ‘Life cycle Activities’ rose to 54%, while the customer view fell to 8%. In the last part, ‘Value’ is heavily discussed (34%). In addition, the dimension with the highest frequency was ‘Life cycle Activities’ with 31% of the total number, followed by ‘Value’ (21%). Furthermore, noticeable from the other dimensions is that ‘Core Products’ (CP) is almost non-existent.

Analysis of combination between strategies and PSS dimensions

Table 8 shows numbers of utterances of each PSS dimension discussed in combination with micro/macrostrategies.

The utterance numbers were tested statistically in the same manner as in Section Analysis by divided parts. As a result, the null hypothesis of independence between the row and column variables is rejected for these tables as well by the Chi-square test with a p value less than 0.01.This means that the PSS dimensions that are primarily discussed are significantly affected by the macro/microstrategies used.

The numbers in italic are above the average in these tables as well. All the numbers are in percentage, in the same manner as those in Tables 7, 8, and 9; 100% corresponds to 1,450 utterances. For example, the time for ‘Life cycle Activities’ (L) to be discussed with the microstrategy ‘Analyzing Solution’ (A) accounts for 18% of the design, as shown in Table 8. In the same way, Table 9 shows the time for ‘Value’ (V) to be discussed with the macrostrategies’ ‘Top-Down’ (TD) accounting for 12%.

The customer view, i.e., ‘Needs and Value’, shares highly in ‘Introducing Problem’ (I) - 68%. This means that most problems were introduced when discussing ‘Needs’ and ‘Value’ of the customer. In addition, for the customer view, i.e., ‘Needs’ and ‘Value’, ‘Top-Down’ (TD) and ‘Decomposing’ (DE) strategies were dominant to be combined, with 81% for ‘Needs’ and 90% for ‘Value’. On the other hand, ‘Life cycle Activities’ (L) were combined 63% with ‘Bottom-Up’ (BU).

The highest percentages were taken out from Tables 8 and 9 to Tables 10 and 11, respectively. Tables 10 and 11 show combinations of a PSS dimension and a micro- and macrostrategy that are addressed most frequently.

Analysis by division with length

To check the robustness of the answers to the three questions, the episode has also been analyzed by dividing it into five parts, with the identical length of utterances instead of the identical numbers. That is, each part was created so that it spent (as closely as possible to) one fifth of the entire length, 4,409 seconds (1 hour, 13 minutes and 29 seconds).

Tables 12, 13, 14, 15, 16, 17, and 18 show the data of the five parts divided by the length, which can be compared with Tables 5 to 11, respectively. As shown, no difference can be found to answer the three questions.

Discussion

General trend of the PSS design

Answering question a in Section What to understand in PSS design, as explained in Table 7, simply put, the entire design episode spent major time on ‘Need’ and ‘Value’ in the beginning, shifted to focus mainly on ‘Life cycle Activities’ with addressing ‘Periphery’ and ‘Finance’, and closed with a focus on ‘Value’. This is in clear contrast to physical product design, where function is mainly reasoned about in the beginning [42]. The high percentages of the total time spent for ‘Life cycle Activities’ (31%), ‘Value’ (21%), and ‘Need’ (15%) are also evidence of the contrast to the design of a physical product, in which, for instance, function, behavior, and structure are sufficiently as used concepts [42]. From this analysis of used concepts, the essence of PSS design seems to be linking, in a design solution, the life cycle activities and customer value anchored with customer need. High frequencies of ‘Periphery’ and ‘Finance’ are caused by the improvement options derived from this particular design. If the discussed improvement options were about the PSS core products, the frequency of CP might in that case have been as high as ‘Periphery’ or ‘Finance’.

Concerning question b, as explained in Tables 5 and 6, as a general trend for the used macrostrategies, the whole design episode began with ‘Top-Down’ and ‘Decomposing Problem’, went through ‘Bottom-Up’, and ended with all of the three. This is in line with some product design episodes analyzed with the same macrostrategies [11]. This implies that a PSS design episode can have a similar pattern of processes as a certain group of product design.

Regarding the microstrategies, it started with ‘Introducing Problem’, ‘Analyzing Problem’, and ‘Analyzing Solution’, went in the middle through more ‘Analyzing Solution’, and finished with ‘Analyzing Solution’. These general trends observed in this particular PSS design follow the general characteristics of a problem-solving process. Regarding microstrategies, similarity like high percentage of time spent on ‘Analyzing Solution’ can be found in the previous analysis of designing a physical product [11]. At the same time, a difference has been found: ‘Introducing Problem’ and ‘Analyzing Problem’, which were not used as encoding alternatives in the based work [11], accounted for as much as 10% and 23%, respectively. Based on this, reasoning about problems seems to be a new type of activity as compared to product design. For clarification, the three questions assumed that it is possible to split a design episode into different stages, and the results show that it is indeed possible.

Described in the previous three paragraphs is a description of the whole design episode containing nine different design solutions shown in Section Outcome of the PSS design - generated ideas for improvement. This paper did not discover how these multiple solutions were generated time wise; e.g., if they were derived in parallel or more in a sequential manner on the timeline. Therefore, there is risk of identifying general patterns like those previously mentioned. However, it is reasonable to make a hypothesis: PSS design begins with ‘Need’ and ‘Value’, addresses mainly ‘Life cycle Activities’ with particular dimensions addressed for solutions, and ends with ‘Value’.

Regarding question c, the combination between ‘Life cycle Activities’ and ‘Analyzing Solution’ was ranked at the top (18%) in terms of frequency as shown in Table 10. In addition, the combination between ‘Life cycle Activities’ and ‘Bottom-Up’ was ranked at the top (20%) (see Table 11).

These facts in this design may give a central role to ‘Life cycle Activities’ in quantitative terms.

Effectiveness of the proposed method for analysis

As described in Section Method proposed and adopted in this research, this article proposes a method for analysis of a PSS design protocol. The results from the analysis using the method showed distinct difference in characteristics of the design process over time. This means that the method is effective to analyze PSS design. This effectiveness is also supported by another piece of research work using protocol analysis of PSS design [43], which is based on the earlier publication (as a conference paper) [12] of this proposed method but extended differently. In sum, one of the new insights brought by this article lies in this unique method for analysis explained in a complete manner.

Factors influencing PSS design

As shown in Table 7, Core Products (CP) was virtually untouched in this PSS design. This is due to the fact that all the improvement options were not directly about the core product. The reason for this can be attributed to the relatively sparse information that designers had about the details of the core product. On the other hand, the designers could and did reason about the ‘Finance’, e.g., by referring to offerings in other sectors. This implies that the time spent in each dimension is dependent on the competence of the designers, as well as the type of offering.

Furthermore, the capacity and skills of the designers are interesting factors that influence the outcomes and the process of the design. A review paper [44] shows the difference between design by an expert and a novice. This design episode was created by master’s course students, i.e., not experienced designers, which is a delimitation of this research. There is a possibility, for instance, for the created design solutions to be less realistic to implement, and the reason for this may be their lack of expertise. Nevertheless, the insight gained in this research can be regarded as a meaningful piece of scientific insight for PSS design in practice for the following reasons. First, there is similarity in problem solving strategies in design between that by an expert and by a non-expert. For instance, Ho [45] found, by a protocol analysis of product design, that both a novice and an expert used bottom-up solving strategies. Second, the designers in this research are senior students at the master’s level, not junior students or novices. Third, carrying out (and reporting) the same experiment in a natural, industrial setting on a real task can be problematic because practitioners may feel embarrassed and/or companies may not allow the recording of such an experiment [16]. Thus, the result (including the proposed method) of this article is valuable despite the uncertainty coming from the characteristics of designers in this experiment. Noteworthy is that the acknowledged article analyzed the PSS design process that was carried out by students [43]. Yet another piece of acknowledged work analyzed processes of decision making in supply chain management by master’s students (instead of experts in marketing, production, etc.) [46].

Issues about encoding

It should be mentioned that the way of encoding the episode based on the PSS Layer Method has the drawback of making it impossible to compare the result of protocol analysis for other types of design such as software. This analysis was conducted by prioritizing the motivation to understand PSS design, and thus by using a modeling method specific to PSS, but with sacrifice of such comparability. However, analysis using a generic modeling method, rather than one specific to PSS, would enable the comparison and thus lead to further understanding of PSS design.

Verifying the encoding, Table 4 clearly shows the difficulty of encoding in the same manner by two different encoders. First of all, sentences are in some cases very short (e.g. ‘Yes.’ and ‘The information from inspection is …’). This is relevant for all the three columns. For the macrostrategies, it can be hard to discriminate among their categories, e.g., ‘Top-down’ and ‘Decomposing Problem’ in the macrostrategies. In the microstrategies, it can be hard to determine exactly when the switch took place between ‘Introducing Problem’ and ‘Analyzing Problem’. In the PSS dimension, an utterance sometimes has multiple aspects, e.g., ‘We don’t know if it’s feasible to take back the product, isn’t it?’ was coded as ‘Needs’ and as ‘Finance’ differently by the two encoders. All of these constitute, in combination, the reasons for the difficulty.

This difficulty is not unique to this case. For instance, another case with a product design [11], which is more simple in its object dimension (‘Function’, ‘Behavior’, and ‘Structure’), has shown that the match ratio between two encodings was 63%, and encoding in this case was done twice by an identical encoder with a 10-day break. Thus, the match ratio between the two encoders in this article should not be overemphasized when questioning the encoding quality. Nevertheless, this uncertainty should be kept in mind in making the analysis.

Implication for development of PSS design methods

From the viewpoint of developing methods/tools to support PSS design, there are several implications. First, it will be important to address need, value, and life cycle activity, as they accounted for 66% of the time of the design case in total. Notably, these three concepts are not addressed in traditional product design. Thus, they should be effectively incorporated into a PSS design method as compared to traditional product design. Second, developing the methods/tools supporting the combinations in Tables 10 and 11 is implied to be more focused on than other combinations. This is based on the assumption that the activities consuming more time have the higher possibility of reducing the time for the design as a whole. It would be of interest to question the research community if, for instance, the process of analyzing solutions at the level of life cycle activities (with the highest ratio in Table 10) has sufficiently been the target of research, or if that process deserves more attention. It should be noted that the ‘partner’ of life cycle activities is analyzing solutions, and neither analyzing problems nor introducing problems, which took the second and third shares in the analyzed PSS design, respectively.

Contribution to design for remanufacturing

How can the result be used to better support design for remanufacturing? First of all, one should bear in mind that remanufacturing goes in hand-in-hand with PSS [2–5]. More precisely, PSS facilitates remanufacturing, and thus PSS design contributes to the design for remanufacturing. Industrial cases also show that PSS design and design for remanufacturing go hand-in-hand [47].

According to the result, PSS design has been found to give a central role to ‘Life cycle Activities’. Remanufacturing is a kind of ‘Life cycle Activity’ and thus should be discussed substantially in PSS design. Indeed, remanufacturing activities such as take back, inspection, maintenance, and repair were discussed in the case design episode. This means that PSS design, even if not guided with specific attention to remanufacturing or the environmental aspect, would go through ‘Life cycle Activities’, which have in many cases a positive contribution to the environmental impact and can be remanufacturing. Thus, knowledge about PSS design such as the result presented in this article contributes to better support the design for remanufacturing. Additional support needed for PSS designers to incorporate remanufacturing may be making them fully aware of remanufacturing as a candidate for ‘Life cycle Activities’.

Concerning the design for remanufacturing as such, it could be said, based on the result, that designers should make sure to sufficiently address the need and value of a customer, as focusing on a remanufacturer’s activities may take away the designers’ attention to them.

Conclusion

This article presented a first protocol analysis of the entire process of a PSS design episode. The proposed and adopted methods were protocol analysis with extension by the authors. This article presented results from investigating what is happening inside a PSS design process, with a focus on the general trends. The insights gained through this research include reasonable hypotheses. First, PSS design begins with need and value, addresses mainly life cycle activities with particular dimensions addressed for solutions, and ends with value. In addition, life cycle activities seem to play a central role in design. This article contributed to understanding of the PSS design process scientifically and in quantitative terms. However, more research is needed to draw stronger conclusions. To do so, the method proposed by this article can be immediately used.

Future work will include continued research to obtain greater understanding of PSS design, of particular interest will be scientific and quantitative understanding of design for remanufacturing. When sufficient knowledge on what to implement is accumulated, research on how to implement it in an organization would become an issue.

Appendix

The categories for the microstrategies including their subcategories are presented in Table 19. Table 20 shows an example of a part of the segmented protocols with coding.

The time column shows what time the specific segment starts. PSS is an abbreviation for a dimension of the PSS Layer Method. The Mi and Ma columns specify which type of micro- and macrostrategies are used, respectively. The D column, for designer, specifies which designer out of the three (labeled 1, 2, and 3) spoke the dialogue. In the ‘Dialogue’ column, the designer’s words are transcribed. In this column, short pauses are represented by ‘…’ in the text.

Authors’ information

Prof. Tomohiko Sakao is from the Division of Environmental Technology and Management, Department of Management and Engineering, Linköping University, Sweden. He is a visiting researcher at the University of Tokyo and at Technical University of Berlin. His research interests include Ecodesign and Integrated Product Service Engineering. Assoc. Prof. Hajime Mizuyama is from the Department of Industrial and Systems Engineering, Aoyama Gakuin University, Japan. His research interests include Collective Intelligence, CSCW, and Group Decision Making.

References

Ijomah WL, Childe SJ: A model of the operations concerned in remanufacture. Int J Prod Res 2007,45(24):5857–5880. 10.1080/00207540601137181

Sundin E, Bras B: Making functional sales environmentally and economically beneficial through product remanufacturing. J Clean Prod 2005,13(9):913–925. 10.1016/j.jclepro.2004.04.006

Mont O, Dalhammar C, Jacobsson N: A new business model for baby prams based on leasing and product remanufacturing. J Clean Prod 2006,14(17):1509–1518. 10.1016/j.jclepro.2006.01.024

Besch K: Product-service systems for office furniture: barriers and opportunities on the European market. J Clean Prod 2005, 13: 1083–1094. 10.1016/j.jclepro.2004.12.003

Kuo TC, Ma H-Y, Huang SH, Hu AH, Huang CS: Barrier analysis for product service system using interpretive structural model. Int J Adv Manuf Technol 2010, 49: 407–417. 10.1007/s00170-009-2399-7

Tischner U, Verkuijl M, Tukker A: First Draft PSS Review. Cologne: Econcept; 2002.

7. Fukushige S, Yamamoto K, Umeda Y: Lifecycle scenario design for product end-of-life strategy. J Remanufacturing 2012.,2(1)

Aurich JC, Fuchs C, Wagenknecht C: Life cycle oriented design of technical product-service systems. J Clean Prod 2006,14(17):1480–1494. 10.1016/j.jclepro.2006.01.019

Hatcher GD, Ijomah WL, Windmill JFC: Design for remanufacture: a literature review and future research needs. J Clean Prod 2011, 19: 2004–2014. 10.1016/j.jclepro.2011.06.019

Eder EW: Design modeling - a design science approach (and Why does industry Not Use It?). J Eng Des 1998,9(4):355–371. 10.1080/095448298261499

Gero JS, Neill TM: An approach to the analysis of design protocols. Des Stud 1998, 19: 21–61. 10.1016/S0142-694X(97)00015-X

Sakao T, Paulsson S, Mizuyama H: Inside a PSS design process: insights through protocol analysis. In International Conference on Engineering Design. Copenhagen; 2011.

Sundin E, Björkman M, Jacobsson N: Analysis of Service Selling and Design for Remanufacturing. In Proceedings of IEEE International Symposium on Electronics and the Environment. San Francisco; 2000:272–277.

Neely A: The servitization of manufacturing: an analysis of global trends. In 14th EurOMA Conference. Ankara; 2007.

Badke-Schaub P, Daalhuizen J, Roozenburg N: Towards a designer-centred methodology: descriptive considerations and prescriptive reflections. In The Future of Design Methodology. Edited by: Birkhofer H. London: Springer; 2011:181–197.

Blessing L, Chakrabarti A: DRM, a Design Research Methodology. London: Springer; 2010.

Cross N: Engineering Designs Methods. Chichester: Wiley; 1989.

Sakao T, Shimomura Y: Service engineering: a novel engineering discipline for producers to increase value combining service and product. J Clean Prod 2007,15(6):590–604. 10.1016/j.jclepro.2006.05.015

Maussang N, Zwolinski P, Brissaud D: Product-service system design methodology: from the PSS architecture design to the products specifications. J Eng Des 2009,20(4):349–366. 10.1080/09544820903149313

Komoto H, Tomiyama T: Integration of a service CAD and a life cycle simulator. CIRP Ann Manuf Technol 2008,57(1):9–12. 10.1016/j.cirp.2008.03.001

Pahl G, Beitz W: Engineering Design: A Systematic Approach. London: Springer-Verlag; 1988.

Morelli N: Product-service systems, a perspective shift for designers: a case study: the design of a telecentre. Des Stud 2003,24(1):73–99. 10.1016/S0142-694X(02)00029-7

Alonso-Rasgado T, Thompson G: A rapid design process for total care product creation. J Eng Des 2006,17(6):509–531. 10.1080/09544820600750579

Blessing L, Chakrabatri A, Wallace KM: An overview of descriptive studies in relation to a general design research methodology. In Designers – The Key to Successful Development. Edited by: Frankenberger E, Badke-Schaub P, Birkhofer H. London: Springer; 1998:42–56.

Blessing LTM: A process-based approach to computer-supported engineering design. Twente: University of Twente; 1994.

Hoffman CM, Joan-Arinyo R: CAD and the product master model. Comput Aided Des 1998,30(11):905–918. 10.1016/S0010-4485(98)00047-5

Isaksson O, Larsson TC, Rönnbäck AÖ: Development of product-service systems: challenges and opportunities for the manufacturing firm. J Eng Des 2009,20(4):329–348. 10.1080/09544820903152663

Altshuller G, Altov H: And suddenly the inventor appeared-TRIZ, the theory of inventive problem solving. Worcester: Technical Innovation Center; 1996.

Kruger C, Cross N: Solution driven versus problem driven design: strategies and outcomes. Des Stud 2006, 27: 527–548. 10.1016/j.destud.2006.01.001

Ericsson KA, Simon HA: Protocol Analysis Verbal Reports as Data. Cambridge, MA: MIT Press; 1993.

Van Someren MW, Bardard YF, Sandberh JAC: The Think Aloud Method: A Practical Guide to Modelling Cognitive Processes. London: Academic Press; 1994.

Carley K: Coding choices for textual analysis: a comparison of content analysis and map analysis. Sociol Methodol 1993, 23: 75–126.

Frankenberger E, Auer P: Standardized observation of team-work in design. Res Eng Des 1997, 9: 1–9. 10.1007/BF01607053

Smagorinsky P: Rethinking protocol analysis from a cultural perspective. Ann Rev Appl Linguist 2001, 21: 233–245.

Hughes J, Parkes S: Trends in the use of verbal protocol analysis in software engineering research. Behav Inform Technol 2003,22(2):127–140. 10.1080/0144929031000081341

Al-Sayed K, Dalton RC, Hölscher C: Discursive design thinking: the role of explicit knowledge in creative architectural design reasoning. Artificial Intelligence for Engineering Design, Analysis and Manufacturing 2010, 24: 211–230. 10.1017/S0890060410000065

Sakao T, Shimomura Y, Sundin E, Comstock M: Modeling design objects in CAD system for service/product engineering. Comput Aided Des 2009,41(3):197–213. 10.1016/j.cad.2008.06.006

Müller P: Integrated Engineering of Products and Services. Layer-based Development Methodology for Product-Service Systems: Technical University of Berlin, Berlin; 2013.

Linstone HA, Turoff M: The Delphi Method Techniques and Applications. Reading, MA: Addison-Wesley Educational Publishers; 1975.

Komatsu, Komtrax http://www.komatsuamerica.com/komtrax

Stempfle J, Badke-Schaub P: Thinking in design teams - an analysis of team communication. Des Stud 2002,23(5):473–496. 10.1016/S0142-694X(02)00004-2

Neill TM, Gero JS, Warren J: Understanding conceptual electronic design using protocol analysis. Res Eng Des 1998,10(3):129–140. 10.1007/BF01607155

Bertoni A: Analyzing product-service systems conceptual design: the effect of colorcoded 3D representation. Des Stud 2013, 34: 763–793. 10.1016/j.destud.2013.02.003

Cross N: Expertise in design: an overview. Des Stud 2004, 25: 427–441. 10.1016/j.destud.2004.06.002

Ho CH: Some phenomena of problem decomposition strategy for design thinking: dierences between novices and experts. Des Stud 2001, 22: 27–45. 10.1016/S0142-694X(99)00030-7

Önkal D, Sayım KZ, Lawrence M: Wisdom of group forecasts: does role-playing play a role? Omega 2012, 40: 693–702. 10.1016/j.omega.2011.01.010

Sundin E, Lindahl M, Ijomah W: Product design for product/service systems - design experiences from Swedish industry. J Manuf Technol Manage 2009,20(5):723–753. 10.1108/17410380910961073

Acknowledgements

The authors express their sincere thanks to all who contributed to this paper, especially to the company that provided us with a valuable opportunity to adopt the PSS offering as a case. Dr. Patrick Müller, a primary developer of the PSS Layer Method from Fraunhofer IPK Berlin, supported us through commenting on a description of the current offering on the PSS Layer Method. Mr. Svante Paulsson supported the analysis of the PSS design. This research was partially supported by a Grant-in-Aid for Creative Scientific Research 2007 to 2011 (19GS0208) funded by the Ministry of Education, Culture, Sports, Science and Technology, Japan. Last not but not the least, three anonymous reviewers are highly appreciated with their insightful and inspiring comments to the earlier versions of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

TS reviewed the literature, initiated the definition of the method, and analyzed the design. HM conducted and supported the analysis of the design. Both authors have read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Sakao, T., Mizuyama, H. Understanding of a product/service system design: a holistic approach to support design for remanufacturing. Jnl Remanufactur 4, 1 (2014). https://doi.org/10.1186/2210-4690-4-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2210-4690-4-1