Abstract

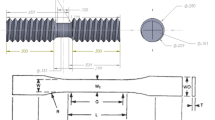

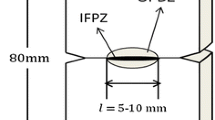

Impact loaded polymers show a variety of strain-rate dependent mechanical properties in their elastic, plastic and failure behaviour. In contrast to purely crystalline materials, the volume of polymeric materials can significantly change under irreversible deformations. In this paper, uni-axial tensile tests were performed in order to measure the dilatation in the Polycarbonate-Acrylnitril-Butadien-Styrol (PC-ABS) Bayblend T65. The accumulation of dilatation was measured at deformation speeds of 0.1 and 500 [mm/s]. Instrumented with a pair of two high-speed cameras, volume segments in the samples were observed. The change in volume was quantified as relation between the deformed and initial volumes of the segments. It was observed that the measured dilatations are of great significance for the constitutive models. This is specifically demonstrated through comparisons of stress-strain relations derived from the two camera-perspectives with isochoric relations based on single-surface observations of the same experiments.

Similar content being viewed by others

References

M. Junginger, Charakterisierung und Modellierung unverstärkter thermoplastischer Kunststoffe zur numerischen Simulation von Crashvorgängen, Doctoral thesis (Fraunhofer EMI, Freiburg, 2004)

S. Kolling, A. Haufe, M. Feucht, P.A. Du Bois, Proceedings to the LS-DYNA Anwenderforum (Bamberg, Germany, 2005)

W. Arnold, E. Rottenkolber, Int. J. Impact Eng. 33, 53 (2006)

Z. Li, J. Lambros, Int. J. Solids Struct. 38, 3549 (2001)

S. Sarva, S. Deschanel, M.C. Boyce, W. Chen, Polymer 48, 2208 (2007)

S. Sarva, A.D. Mulliken, M.C. Boyce, Int. J. Solids Struct. 44, 2381 (2007)

Y. Sato, M. Yoshida, K. Nagayama, Y. Horie, Int. J. Impact Eng. 35, 1778 (2008)

S. Katz, E. Grossman, I. Gouzman, M. Murat, E. Weizel, H.D. Wagner, Int. J. Impact Eng. 12, 1606 (2008)

S. Hiermaier, W. Riedel, C.J. Hayhurst, R.A. Clegg, C.M. Wentzel, Advanced Material Models for Hypervelocity Impact Simulations, Final report to European Space Agency project No. 12400/97/NL/PA(SC), Fraunhofer EMI, Freiburg, Germany, 1999

Structures under Crash and Impact (Springer, New York, 2008)

Bridgman, Studies in Large Plastic Flow and Fracture (McGraw Hill, New York, 1952)

L. Peroni, M. Avalle, M. Peroni, Int. J. Impact Eng. 35, 644 (2008)

M. Wicklein, Zellulares Aluminium: Entwicklung eines makromechanischen Materialmodells mittels mesomechanischer Simulation, Doctoral Thesis (Fraunofer EMI, Freiburg, 2006)

H. DorMohammadi, A.R. Khoei, Int. J. Solids Struct. 45, 631 (2008)

R.A. Duckett, B.C. Goswami, L.S.A. Smith, I.M.Ward, A. M. Zihlif, British Polymer J. 10, 11 (1978)

The Physics of Polymers (Springer, Berlin, 1996)

T.N. Krupenkin, G.H. Fredrickson, Macromolecules 32, 5036 (1999)

J. Rottler, M.O. Robbins, Phys. Rev. E 68, 011801 (2003)

C.B. Bucknall, Polymer 48, 1030 (2007)

C. G’Sell, J.M. Hiver, A. Dahoun, A. Souahi, J. Mater. Sci. 27, 5031 (1992)

S. Aloui, R. Othman, A. Poitou, P. Guegan, S. El-Borgi, Mech. Res. Comm. 35, 392 (2008)

C. G’Sell, J. M. Hive, A. Dahoun, Int. J. Solids Struct. 39, 3857 (2002)

C. G’Sell, J.-M. Hiver, French Patent Nr. 010542100, Bull Of INPI, 23 April 2001

F. Addiego, A. Dahoun, C. G’Sell, J.-M. Hiver, Polymer 47, 4387 (2006)

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Hiermaier, S., Huberth, F. Volume dilatation in a polycarbonate blend at varying strain rates. Eur. Phys. J. Spec. Top. 206, 173–181 (2012). https://doi.org/10.1140/epjst/e2012-01598-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1140/epjst/e2012-01598-x