Abstract

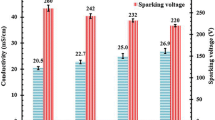

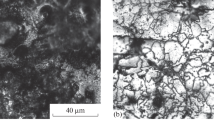

The effect of laser treatment of aluminum samples on the properties of the surface hydroxide oxide layer is studied. It is shown that treatment in air leads to an increase in the thickness of the oxide layer and the almost complete disappearance of hydroxide forms, which results in deterioration of the protective properties of this layer due to its higher defectiveness and porosity. It is found that the optimal treatment regime for aluminum, the surface of which is covered by an oxide layer with a significant fraction of hydroxides, is laser irradiation in an inert argon gas medium with small (1–2 vol %) oxygen content. Laser treatment leads to the formation of a protective surface layer that effectively inhibits the anodic dissolution of aluminum in a model corrosion medium, borate buffer solution at pH 7.4. It is shown that the initial hydroxide oxide film and the oxide film formed during laser treatment processing are hydrophilic, that is, they are well moistened with water. The surface treatment of aluminum in the initial state and after laser irradiation with a solution of vinyltriethoxysilane (VTES) leads to the formation of a hydrophobic adsorption layer and a significant decrease in the currents of anodic dissolution. Using X-ray photoelectron spectroscopy, it is shown that silane adsorption occurs both with the participation of silicon atoms and carbon atoms of an alkene bond. The hydrophobic layer of adsorbed silane on the laser-treated surface has a greater thickness and has a higher inhibiting effect on the anodic dissolution of aluminum than in the case of the initial aluminum surface.

Similar content being viewed by others

REFERENCES

Todt, F., Korrosion und Korrosionsschutz, Berlin: Walter de Gruyter, 1961.

Corrosion, Shreir, L.L., Ed. London: Newnes-Butterworths, 1976.

Semenova, I.V., Florianovich, G.M., and Khoroshilov, A.V., Korroziya i zashchita ot korrozii (Corrosion and Corrosion Protection), Moscow: Fizmatlit, 2002.

Kaluzhina, S.A. and Minakova, T.A., Passivatsiya i lokal’naya aktivatsiya alyuminiya (Passivation and Local Activation of Aluminum), Saarbrucken: LAP Lambert Academic, 2015.

Sinyavskii, V.S., Val’kov, V.D., and Kalinin, V.D., Korroziya i zashchita alyuminievykh splavov (Corrosion and Protection of Aluminum Alloys), Moscow: Metallurgiya, 1986.

Chukin, G.D., Stroenie oksida alyuminiya i katalizatorov gidroobesserivaniya. Mekhanizmy reaktsii (The Structure of Aluminum Oxide and Hydrodesulfurization Catalyst. Reaction Mechanisms), Moscow: Printa, 2010.

Kiselev, V.F. and Krylov, O.V., Adsorbtsionnye protsessy na poverkhnosti poluprovodnikov i dielektrikov (Adsorption on the Surface of Semiconductors and Dielectrics), Moscow: Nauka, 1978.

Masuda, H., Nagae, M., Morikawa, T., and Nishio, K., Long-range-ordered anodic porous alumina with reduced hole interval formed in highly concentrated sulfuric acid solution, Jpn. J. Appl. Phys.: Lett. Exp. Lett., 2006, vol. 45, nos. 12–16, pp. L406–L408.

Gruss, L.L. and Neill, W., Anodic spark reaction products in aluminate, tungstate and silicat solutions, J. Electrochem. Technol., 1963, vol. 1, nos. 9–10, pp. 283–287.

Neill, W. and Gruss, L.L., Anodic film growth by anion deposition in aluminate, oungstate and phosphate solutions, J. Electrochem. Soc., 1963, vol. 110, no. 8, pp. 853–855.

Thompson, G.E., Porous anodic alumina: Fabrication, characterization and applications, Thin Solid Films, 1997, vol. 297, nos. 1–2, pp. 192–201.

Zhu, X.F., Li, D.D., Song, Y., and Xiao, Y.H., The study on oxygen bubbles of anodic alumina based on high purity aluminum, Mater. Lett., 2005, vol. 59, nos. 24–25, pp. 3160–3163.

Takahashi, H., Fujimoto, K., and Nagayama, M., Effect of pH on the distribution of anions in anodic oxide films formed on aluminum in phosphate solutions, J. Electrochem. Soc., 1988, vol. 135, no. 6, pp. 1349–1353.

Kolotyrkin, V.I. and Knyazheva, V.M., Possibilities of high-energy methods of metal surface treatment for corrosion protection, Zashch. Met., 1991, vol. 27, no. 2, pp. 184–186.

Kurbatkina, E.I., Rakoch, A.G., Belov, N.A., and Avanesyan, T.G., Corrosion resistance of boron-bearing aluminum alloys and its increase after plasma electrolytic oxidation, Prot. Met. Phys. Chem. Surf., 2014, vol. 50, no. 7, pp. 889–892.

Weber, M.J., Handbook of Lasers, Boca Raton: CRC Press, 2001.

Kharanzhevskii, E.V. and Krivilev, M.D., Fizika lazerov, lazernye tekhnologii i metody matematicheskogo modelirovaniya lazernogo vozdeistviya na veshchestvo (Laser Physics, Laser Technologies, and Methods for Mathematical Modeling of Laser Treatment on Matter), Izhevsk: Udmurt. Gos. Univ., 2011.

Gremaud, M., Carrad, M., and Kurz, W., The microstructure of rapidly solidified Al–Fe alloys to laser surface treatment, Acta Metal. Mater., 1990, vol. 38, no. 12, pp. 2587–2599.

Grigoryants, A.G. and Safonov, A.N., Lazernaya tekhnika i tekhnologiya. Kniga 3. Metody poverkhnostnoi lazernoi obrabotki (Laser Technique and Technology, Book 3: Methods of the Surface Laser Treatment), Moscow: Vysshaya Shkola, 1987.20.

Borisova, E.M., Gil’mutdinov, F.Z., Reshetnikov, S.M., Kharanzhevskii, E.V., and Chausov, F.F., RF Patent 2622466, 2017.

Atlas of Eh-pH Diagrams, Intercomparison of Thermodynamic Databases, Geological Survey of Japan Open File Report No. 419, Tsukuba: Natl. Inst. Adv. Ind. Sci. Technol., Res. Center Deep Geol. Environ., Naoto TAKENO, 2005, pp. 22–23. http://www.eosremediation.com/download/Chemistry/Chemical%20Properties/Eh_pH_Diagrams.pdf.

Nefedov, V.I., Rentgenoelektronnaya spektroskopiya khimicheskikh soedineniy (X-ray Electron Spectroscopy of Chemical Compounds), Moscow: Khimiya, 1984.

Grigorov, O.N., Rukovodstvo k prakticheskim rabotam po kolloidnoi khimii (Guide for Practical Works on Colloid Chemistry), Moscow: Khimiya, 1964.

Boinovich, L.B. and Emelyanenko, A.M., Hydrophobic materials and coatings: principles of creation, properties and application, Russ. Chem. Rev., 2008, vol. 77, no. 7, pp. 583–600.

Funding

This work was carried out as part of the State Assignment no. AAAA-A17-11722250040-0 using the equipment of the Shared Access Center for Physical and Physicochemical Methods of Analysis, Investigation of Properties and Characteristics of Surfaces, Nanostructures, Materials, and Products of the Udmurt Federal Research Center, Ural Branch, Russian Academy of Sciences.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by K. Lazarev

Rights and permissions

About this article

Cite this article

Borisova, E.M., Gilmutdinov, F.Z., Reshetnikov, S.M. et al. Effect of Laser Treatment and Hydrophobization on the Corrosion-Electrochemical Behavior of Aluminum. Inorg. Mater. Appl. Res. 11, 520–525 (2020). https://doi.org/10.1134/S2075113320030065

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113320030065