Abstract

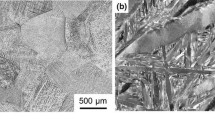

The influence of the warm isothermal (723 K) rolling in grooved rolls on the grain structure, martensitic transformation temperatures, and inelastic properties of Ti49.2Ni50.8 (at %) alloy is investigated. It is shown that transition from initial coarse-grained structure to microand submicrocrystalline structures of samples occurs as a result of rolling with the intense deformation to 1.8. The inelastic properties (superelasticity and shape memory effects) are studied under torsion deformation. The value of the superelasticity effect (including the elastic deformation) was determined in isothermal (295 K) “loading–unloading” cycles. The value of the shape memory effect is equal to the recovery of inelastic deformation under heating of unloaded samples. The accumulated plastic deformation corresponds to the residual deformation after the completion of shape recovery under heating. The total inelastic deformation under torsions of rolled sample reaches 8.5–9.5% (99% of the degree of shape recovery), the shape memory effect is 5–6%, and the superelasticity effect is 3–4%.

Similar content being viewed by others

References

Dudarev, Ye.F., Bakach, G.P., Kolobov, Yu.R., Ivanov, K.V., Lotkov, A.I., Grishkov, V.N., Valiyev, R.Z., and Ivanov, M.B., Localization of martensitic deformation on mesoand macroscale levels in large grain and sub-micro grain alloys with shape memory, Phys. Mesomech., 2004, vol. 7, sp. No. 1, pp. 127–130.

Prokof’yev, Ye.A., Structure and properties of ultrafine grained Ti–Ni alloys obtained by severe plastic deformation, Vest. Ufim. Gos. Aviat. Univ., 2006, vol. 8, pp. 169–171.

Lotkov, A.I., Grishkov, V.N., Kopylov, V.I., Baturin, A.A., and Girsova, N.V., Effect of severe plastic deformation of Ti50Ni47.3Fe2.7 on martensitic transformation and shape memory effect, Prspekt. Mater., 2007, Special issue, part. 2, pp. 396–398.

Khmelevskaya, I.Yu., Prokoshkin, S.D., Dobatkin, S.V., Trubitsyna, I.B., Tatyanin, E.V., Stolyarov, V.V., Prokofyev, Ye.A., Brailovski, V., and Tyurenn, S., Features reversible deformation and stress reactive alloys of TiNi shape memory after thermomechanical treatment and severe plastic deformation, Deform. Razrush. Mater., 2007, no. 2, pp. 33–37.

Khmelevskaya, I.Yu., Prokoshkin, S.D., Trubitsyna, I.B., Belousov, M.N., Dobatkin, S.V., Tatyanin, E.V., Korotitskiy, A.V., Brailovski, V., Stolyarov, V.V., and Prokofiev, E.A., Structure and properties of Ti-Nibased alloys after equal-channel angular pressing and high-pressure torsion, Mater. Sci. Eng. A, 2008, vol. 481–482, pp. 119–122.

Pushin, V.G., Lotkov, A.I., Kolobov, Yu.R., Valiyev, R.Z., Dudarev, Ye.F., Kuranova, N.N., Dyupin, A.P., Gunderov, D.V., and Bakach, G.P., On the nature of the anomalously high plasticity of highstrength titanium nickelide alloys with shape memory effects: I. Initial structure and mechanical properties, Phys. Met. Metallogr., 2008, vol. 106, pp. 520–530.

Grishkov, V.N., Lotkov, A.I., Dudarev, Ye.F., Girsova, N.V., and Tabachenko, A.A., Effect of severe plastic deformation on microstructure and martensitic transformations in titanium nickelide, Fiz. Mezomekh., 2006, vol. 9, Special issue, pp. 95–98.

Lotkov, A.I., Grishkov, V.N., Dudarev, Ye.F., Girsova, N.V., and Tabachenko, A.N., Formation of ultrafine state, martensitic transformation and inelastic properties of after abc-pressing, Vopr. Materialoved., 2008, no. 1, pp. 161–165.

Lotkov, A.I., Grishkov, V.N., Dudarev, Ye.F., Koval’, Yu.N., Girsova, N.V., Kashin, O.A., Tabachenko, A.N., Firstov, G.S., Timkin, V.N., and Zhapova, D.Yu., Ultrafine structure and martensitic transformations in titanium nickelide after a warm abcpressing, Inorg. Mater.: Appl. Res., 2011, vol. 2, pp. 548–555.

Lotkov, A.I., Grishkov, V.N., Kashin, O.A., Baturin, A.A., Zhapova, D.Yu., Girsova, N.V., Timkin, V.N., Krukovskiy, K.V., and Bratchikov, A.D., Formation of ultrafine-grained structure of titanium nickelide with stepwise decreasing temperature multipass warm rolling, Perspekt. Mater., 2011, no. 13, pp. 931–938.

Lotkov, A.I., Kashin, O.A., Grishkov, V.N., Krukovskiy, K.V., Zhapova, D.Yu., and Smolyazhenko, Yu.V., Effect of warm rolling on the patterns of deformation and fracture tensile alloy titanium nickelide, Perspekt. Mater., 2011, no. 13, pp. 401–410.

Grishkov, V.N., Lotkov, A.I., Dudarev, Ye.F., Kudinova, Ye.D., Ivanov, K.V., Maletkina, T.Yu., and Ivanov, Yu.F., Martensitic transformations in nanostuctured alloys based on titanium nickelide produced by severe deformation of rolling, Phys. Mesomech., 2004, vol. 7, Special issue, part 2, pp. 26–29.

Prokoshkin, S.D., Brailovski, V., Khmelevskaya, I.Yu., Dobatkin, S.V., Inayekyan, K.E., Turilina, V.Yu., Demers, V., and Tat’yanin, Ye.V., Creation of substructure and nanostructure in thermomechanical treatment and control of functional properties of Ti–Ni–alloys with shape memory effect, Metal. Sci. Heat Treat., 2005, vol. 47, pp. 182–187.

Prokoshkin, S.D., Brailovski, V., Khmelevskaya, I.Yu., Dobatkin, S.V., Inayekyan, K.E., Demers, V., Bastarache, Ye., and Tat’yanin, Ye.V., Formation of a nanocrystalline structure upon severe rolling plastic deformation and annealing and improvement of set of functional properties of Ti–Ni alloy, Bull. Russ. Acad. Sci.: Phys., 2006, vol. 70, pp. 1536–1541.

Prokoshkin, S.D., Brailovski, V., Inaekyan, K.E., Demers, V., Khmelevskaya, I.Yu., Dobatkin, S.V., and Tatyanin, E.V., Structure and properties of severely cold-rolled and annealed Ti-Ni shape memory alloys, Mater. Sci. Eng. A, 2008, vols. 481–482, pp. 114–118.

Ryklina, Ye.P., Prokoshkin, S.D., Chernavina, A.A., and Perevoshchikova, N.N., Investigation on the influence of thermomechanical conditions of induction and structure on the shape memory effect in the Ti–Ni alloy, Inorg. Mater.: Appl. Res., 2010, vol. 1, pp. 188–194.

Ryklina, Ye.P., Prokoshkin, S.D., and Chernavina, A.A., Peculiarities of abnormally high shape memory effects in thermomechanically treated Ti–Ni alloys, Inorg. Mater.: Appl. Res., 2013, vol. 4, pp. 348–355.

Kuranova, N.N., Gunderov, D.V., Uksusnikov, A.N., Luk’yanov, A.V., Yurchenko, L.I., Prokof’yev, Ye.A., Pushin, V.G., and Valiev, R.Z., Effect of hHeat treatment on the structural and phase transformations and mechanical properties of TiNi alloy subjected to severe plastic deformation by torsion, Phys. Met. Metallogr., 2009, vol. 108, pp. 556–568.

Kuranova, N.N., Pushin, V.G., Uksusnikov, A.N., Yurchenko, L.I., Gunderov, D.V., and Valiyev, R.Z., Effect of severe plastic deformation on the phase and structural transformations and mechanical properties of metastable austenitic Ti–Ni alloys, Russian Metall. (Metally), 2010, no. 4, pp. 296–300.

Shutilin, Yu.F., Reverse torsion pendulum, USSR Patent 978005, 1982.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.I. Lotkov, Yu.N. Koval, V.N. Grishkov, D.Yu. Zhapova, V.N. Timkin, G.S. Firstov, 2015, published in Perspektivnye Materialy, 2015, No. 5, pp. 50–61.

Rights and permissions

About this article

Cite this article

Lotkov, A.I., Koval, Y.N., Grishkov, V.N. et al. Influence of deformation during warm rolling on martensitic transformation temperatures and the value of superelasticity and shape memory effects in Ti49.2Ni50.8 (at %) alloy. Inorg. Mater. Appl. Res. 6, 498–505 (2015). https://doi.org/10.1134/S2075113315050093

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113315050093