Abstract

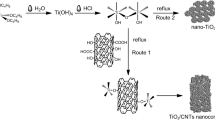

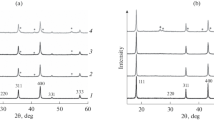

A catalyst for oxidation of carbon black based on potassium dititanate has been synthesized. The catalyst has been fabricated by impregnation of oxidized titanium surface additionally modified with a sublayer of anatase nanoparticles by potassium hydroxide. It has been shown that the synthesized composites exhibit high capacity for oxidation of diesel carbon black, while the applied catalytic layer is characterized by resistance to adhesive and cohesive destruction along with a satisfactory resistance to thermal shock and impact of catalyst poisons. The temperatures of initiation and termination of the catalytic process are in the range 340–550°С and comply with the temperature ranges of the practically applied catalysts.

Similar content being viewed by others

REFERENCES

Krylova, A.V. and Mikhailichenko, A.I., Khim. Tekhnol., 2003, no. 2, p. 13.

Krishna, K., Bueno-López, A., Makkee, M., and Moulijn, J.A., Appl. Catal., B, 2007, vol. 75, p. 201.

Guido, S., Serra, V., Badini, C., and Specchia, V., Ind. Eng. Chem. Res., 1997, vol. 36, no. 6, p. 2051.

Sui, L., Yu, L., and Zhang, Y., Energy Fuels, 2006, vol. 20, p. 1392.

Doorn, J., Varloud, J., Moriaudeau, P., and Perrichon, V., Appl. Catal., B, 1992, vol. 1, p. 117.

Banus, E.D., Milt, V.G., Miro, E.E., and Ulla, M.A., Appl. Catal., A, 2010, vol. 379, p. 95.

Turakulova, A.O., Zaletova, N.V., and Lunin, V.V., Russ. J. Phys. Chem. A, 2010, vol. 84, no. 8, p. 1309.

Gao, Y., Wu, X., and Liu, S., RSC Adv., 2016, vol. 6, p. 57033.

Flouty, R., Abi-Aad, E., Siffert, S., and Aboukaıs̈, A., Appl. Catal., B, 2003, vol. 46, p. 145.

Gross, M.S., Ulla, M.A., and Querini, C.A., Appl. Catal., A, 2009, vol. 360, p. 81.

Zhang, Z., Zhang, Y., Wang, Z., and Gao, X., J. Catal., 2010, vol. 271, p. 12.

Gong, C., Song, Ch., Pei, Y., et al., Ind. Eng. Chem. Res., 2008, vol. 47, p. 4374.

Peng, X., Lin, H., Shangguan, W., and Huang, Z., Ind. Eng. Chem. Res., 2006, vol. 45, p. 8822.

An, H., Kilroy, C., and McGinn, P.J., Catal. Today, 2004, vol. 98, p. 423.

Meng, X., Wang, Q., et al., Kinet. Catal., 2012, vol. 53, no. 5, p. 560.

Wang, Q., Chung, J.-Sh., and Guo, Z., Ind. Eng. Chem. Res., 2011, vol. 50, p. 8384.

Meng, X., Gao, Y., et al., China Pet. Process. Petrochem. Technol., 2012, vol. 14, no. 2, p. 50.

Kondrikov, N.B., Rudnev, V.S., Vasil’eva, M.S., et al., Khim. Interesakh Ustoich. Razvit., 2005, vol. 13, no. 6, p. 851.

Vasil'eva, M.S., Rudnev, V.S., Tyrina, L.M., et al., Russ. J. Appl. Chem., 2005, vol. 78, no. 11, p. 1859.

Vasil'eva, M.S., Rudnev, V.S., Kondrikov, N.B., et al., Russ. J. Appl. Chem., 2004, vol. 77, no. 2, p. 218.

Lukiyanchuk, I.V., Rudnev, V.S., and Tyrina, L.M., Surf. Coat. Technol., 2016, vol. 307, p. 1183.

Karakurkchi, A., Sakhnenko, M., Ved, M., et al., East.-Eur. J. Enterp. Technol., 2017, vol. 5, no. 10 (89), p. 12.

Lebukhova, N.V., Rudnev, V.S., Chigrin, P.G., et al., Surf. Coat. Technol., 2013, vol. 231, p. 144.

Lebukhova, N.V., Rudnev, V.S., Kirichenko, E.A., et al., Surf. Coat. Technol., 2015, vol. 261, p. 344.

Karpovich, N.F., Korol’kov, I.V., Makarevich, K.S., et al., Fundam. Probl. Sovrem. Tekhnol. Materialoved., 2012, vol. 9, no. 1, p. 34.

Gorokhovskii, A.V., RF Patent 2326051, 2008.

Wang, Q., Guo, Z., and Chung, J.-Sh., Mater. Res. Bull., 2009, vol. 44, p. 1973.

Rudnev, V.S., Malyshev, I.V., et al., Prot. Met. Phys. Chem. Surf., 2012, vol. 48, no. 4, p. 455.

Vasilyeva, M.S., Rudnev, V.S., Wiedenmann, F., et al., Appl. Surf. Sci., 2011, vol. 258, p. 719.

ACKNOWLEDGEMENTS

The present study was partially supported by the “Far East” Program of Basic Research (project no. 18-3-034).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by D. Marinin

Rights and permissions

About this article

Cite this article

Chigrin, P.G., Kirichenko, E.A., Rudnev, V.S. et al. Catalytic Properties of K2Ti2O5 + K2Ti4O9/TiO2/TiO2 + SiO2/Ti Composites and Their Resistance to Environment Effects during the Process of Carbon Black Oxidation. Prot Met Phys Chem Surf 55, 109–114 (2019). https://doi.org/10.1134/S2070205119010088

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2070205119010088