Abstract

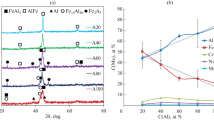

This work is devoted to the deposition of coatings based on FeNiCrWMoCoCB metallic glasses on a surface made of 35 steel; the deposition is carried out by electrospark machining in a medium of granules of metals and alloys used as electrode materials. X-ray diffraction analysis showed that an amorphous phase is predominant in the composition of coatings. At a temperature of 1100°C, the amorphous phase crystallizes in borocarbide of the M23(C,B)6 type, an intermetallic of iron, nickel, and chromium, and αFe phase. Polarization tests of the coating in the NaCl solution (3.5%) demonstrate a lower corrosion current and a higher polarization resistance compared with the 35 steel. It is found during the study of a heat resistance at 600, 700, and 800°C that the use of the FeNiCrWMoCoCB coating on the 35 steel enhances a resistance of its surface to a high-temperature gas corrosion in 8.7, 6.3, and 3.0 times, respectively (the experiment time was 40 h). The wear resistance of the FeNiCrWMoCoCB coatings in a dry sliding wear mode at loadings of 10 and 25 N was 2.2 and 1.7 times higher than for the 35 steel. The samples with the coatings based on the FeNiCrWMoCoCB metallic glasses show a high catalytic activity for a decomposition of a methylene blue solution as at the presence of hydrogen peroxide, as well as without it.

Similar content being viewed by others

REFERENCES

Klement, W., Willens, R.H., and Duwez, P.O.L., Nature, 1960, vol. 187, p. 869.

Wang, P., Wang, J.-Q., Li, H., et al., J. Alloys Compd., 2017, vol. 701, p. 759.

Qin, X.D., Zhu, Z.W., Liu, G., et al., Sci. Rep., 2015, vol. 5, p. 18226.

Ramya, M., Karthika, M., Selvakumar, R., et al., J. Alloys Compd., 2017, vol. 696, p. 185.

Liu, P., Zhang, J.L., Zha, M.Q., et al., ACS Appl. Mater. Interfaces, 2014, vol. 6, p. 5500.

Deng, Z., Zhang, X.H., Chan, K.C., et al., Chemosphere, 2017, vol. 174, p. 76.

Zhang, C., Zhu, Z., Zhang, H., et al., J. Phys. Chem. Solids, 2017, vol. 110, p. 152. https://doi.org/10.1016/j.jpcs.2017.06.010

Lan, X., Wu, H., Liu, Y., et al., Mater. Charact., 2016, vol. 120, p. 82.

Cheng, J., Wang, B., Liu, Q., et al., J. Alloys Compd., 2017, vol. 716, p. 88.

Burkov, A.A., Pyacin, S.A., Ermakov, M.A., et al., J. Mater. Eng. Perform., 2017, vol. 26, p. 901.

Burkov, A.A., Pyachin, S.A., Metlitskaya, L.P., et al., Uprochnyayushchie Tekhnol. Pokrytiya, 2013, vol. 5, no. 101, p. 16.

Burkov, A.A., Materialy 14-oi regional’noi nauchnoi konferentsii. “Fizika: fundamental’nye i prikladnye issledovaniya, obrazovanie” (Proc. 14th Regional Scientific Conference “Physics: Fundamental and Applied Researches, Education”), Khabarovsk, 2016, p. 217.

Verkhoturov, A.D., Formirovanie poverkhnostnogo sloya metallov pri elektroiskrovom legirovanii (Metals’ Surface Layer Formation under Electro-Spark Doping), Vladivostok: Dal’nauka, 1995, p. 323.

Burkov, A.A., Pyachin, S.A., Zaitsev, A.V., et al., Pis’ma Mater., 2016, vol. 6, no. 3 (23), p. 153.

Young, D.J., High Temperature Oxidation and Corrosion of Metals, London: Elsevier, 2008.

Anis, M., Rainforth, W.M., Davies H.A., Wear, 1994, vol. 172, p. 135.

Bolelli, G., Candeli, A., Lusvarghi, L., et al., Wear, 2017, vols. 378–379, p. 68.

Wang, X., Pan, Y., Zhu, Z., Wu, J., et al., Chemosphere, 2014, vol. 117, p. 638.

Serrà, A., Grau, S., Gimbert-Suriñach, C., et al., Appl. Catal., B, 2017, vol. 217, p. 81.

Sohn, K., Kang, S.W., Ahn, S., et al., Environ. Sci. Technol., 2006, vol. 40, p. 5514.

ACKNOWLEDGMENTS

This work was supported by the government of the Khabarovsk krai, order dated May 19, 2017, no. 319-rp.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by N. Saetova

Rights and permissions

About this article

Cite this article

Burkov, A.A., Zaitsev, A.V., Syui, A.V. et al. Corrosion, Mechanical and Catalytic Properties of Coatings Based on FeNiCrWMoCoCB Metallic Glasses. Prot Met Phys Chem Surf 55, 102–108 (2019). https://doi.org/10.1134/S2070205119010076

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2070205119010076