Abstract

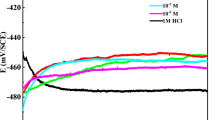

Corrosion behavior of electrolytic coated carbon steel in 3% NaCl solution was investigated using potentiodynamic polarization, lineer polarization resistance, chronoamperometry, open circuit potential as a function of time and impedance (EIS) measurements. Zn and Ni coated carbon steel surfaces immersed into 3% NaCl solution during 1, 5 and 10 days were characterized using scanning electron microscope (SEM). According to the experimental results, nickel coated carbon steel corrosion resistance was higher than that of Zn coating. Accordingly, the corrosion rate of nickel coated carbon steel decreased by 89.6% compared to the zinc coating.

Similar content being viewed by others

References

Ortiz, Z.I., Diaz-Arista, P., Meas, Y., et al., Corrosion Sci., 2009, vol. 51, p. 2703.

Pistofidis, N., Vourlias, G., Chaliampalias, D., et al., Polychroniadis, Surf. Interface Analysis, 2006, vol. 38, p. 252.

Zhang, X.G., Corrosion Electrochemistry of Zinc, N.Y.: Plenum Press., 1996.

Rahsepar, M. and Bahrololoom, M.E., Corrosion Sci., 2009, vol. 51, p. 2537.

Hambu, Y., Tifouti, L., and Pedraza, F., Corrosion Sci., 2010, vol. 52, p. 1883.

Motfe, C., Naury, N., Olivier, M.G., et al., Surf. Coat. Technol., 2005, vol. 200, p. 2366.

Yadav, A.P., Nishikata, A., and Tsuru, T., Corrosion Sci., 2004, vol. 46, p. 169.

Barranco, V., Feliu, S., Jr., and Feliu, S., Corrosion Sci., 2004, vol. 46, p. 2203.

Suzuki, I., Corrosion Sci., 1985, vol. 25, p. 1029.

Chunga, S.C., Chengb, J.R., Chioub, S.D., and Shiha, H.C., Corrosion Sci., 2000, vol. 42, p. 1249.

Lodhi, Z.F., Mol, J.M.C., Hovestad, A., et al., Surf. Coat. Technol., 2009, vol. 203, p. 1415.

Abou-Krisha, M.M., Rageh, H.M., and Matter, E.A., Surf. Coat. Technol., 2008, vol. 202, p. 3739.

Tian, W., Xie, F.Q., Wu, X.Q., and Yang, Z.Z., Surf. Interface Analysis, 2009, vol. 41, p. 251.

Kelly, R.G., Scally, J.R., Shoesmith, D.W., and Buncheit, R.G., Electrochemical Techniques in Corrosion Science and Engineering, 1st ed., N.Y.: Marcel Dekker, Inc., 2003, p. 205.

Hamlaui, Y., Pedraza, F., and Tifouti, L., Corrosion Sci., 2008, vol. 50, p. 1558.

Deslouis, C., Duprat, M., Chr. Tournillon, Corrosion Sci., 1989, vol. 29, p. 13.

Cachet, C., Ganne, F., Maurin, G., et al., Electrochim. Acta, 2002, vol. 47, p. 3409.

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

Rights and permissions

About this article

Cite this article

Ünal, H.I., Zor, S. & Gökergil, H.M. Corrosion behavior of Zn and Ni coated carbon steels in 3% NaCl. Prot Met Phys Chem Surf 49, 591–596 (2013). https://doi.org/10.1134/S2070205113050158

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2070205113050158